SEA Gate 2 DG R1 El manual del propietario

- Categoría

- Abridor de puerta

- Tipo

- El manual del propietario

GATE 2 DG R1

(Cod. 23023025)

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

SEA S.p.A.

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. +39 0861 588341 r.a. Fax +39 0861 588344

www.seateam.com

67411385

Italiano

English

Français

Español

CENTRALE ELETTRONICA PER 1 O 2 MOTORI A 230V/115V

ELECTRONIC CONTROL UNIT FOR 1 OR 2 230V/115V MOTORS

ARMOIRE DE COMMANDE POUR 1 OU 2 MOTEURS EN 230V/115V

CENTRAL ELECTRÓNICA PARA 1 O 2 MOTORES A 230V/115V

Rev.07 - 12/2014

67411385

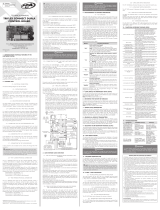

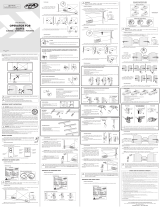

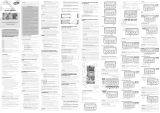

CN1 = Input/output connectors

CN2 = Limit switch, 24V~, Electrolock connector

CN3 = M1 Motors and capacitors connector

CN4 = M2 motors and capacitors connector

CN5 = Courtesy light output connector

CN6 = Power supply connector

CN7 = Encoder connector

CNA = RX Receiver connector

CNP = Porgramming connector

EXP = Expansion module connector / LE Card

JOLLY = Jolly and Jolly 2 connector

DS = Programming display

OK = Programming button

DOWN = Programming button

UP = Programming button

T1 = Motors piloting Triac

T2 = Motors piloting Triac

R1 = Motors comand relay

R2 = Courtesy light comand relay

R3 = Photocell autotest relay

R4 = Electrolock relay

F1 = Accessories 1A fuse

F2 = 6.3AT fuse on 230V/10AT on 115V

F3 = 6.3A Electrolock fuse

TR1 = Power transformer

24

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

COMPONENTS

TECHNICAL SPECIFICATIONS

Control unit power supply: 230 Vac 50/60 Hz - 115Vac 50/60 Hz

Absorption in stand by: 30 mA

Environment temperature : -20°C +50°C

Specifications of external enclosure: 325,7 X 246 X 140

RECEIVER RX

168 mm

174 mm

CNP

CN7

EXP

JOLLY

CNA

CN6

CN5

CN4

CN3

CN1 CN2

F1

UP DOWN OK

F2

F3

R2

R1

T1 T2

TR1

R4

R3

DS

JOLLY-JOLLY2

1 2

ON

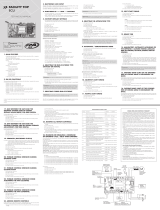

CN1

CNP

DS1

POTENC

M2

M1

1 2 4

P01 D1 P11 P02 D2 P12 I1

5 6 7

I2

GND

I3 I4

3 8 9 10 11

+ -

LE CARD

Rev.07 - 12/2014

67411385

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

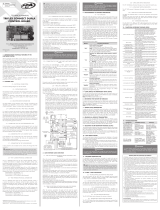

1

2

3 4

5 6

7 8

9

10

11

12

13

CN1

Start

Stop

Common

Antenna

START Pedestrian

Common

Photocell 1

Common

ANT COM STRT

STPD

STOP COM PH1 PH2

EDG1

COM 24VA FLS

Safety edge 1

Photocell 2

Lamp

(500mA max)

+

-

Safety edge 2

AUX

(24V 800mA

max)

24V~

(800 mA max)

24VPh

(800 mA max)

14

15

16 17

18 19

20 21

22

23

CN2

Electrolock

24

25

26 27

28

CN3

29

30

31 32

33

CN4

M1

M2

JUMPERS

1

2

3 4

5 6

7 8

9

10

11

12

13

CN1

+

-

EDG2

LSO1 LSC1 LSO2 LSC2 COM 24V~ 24VPH LOCK CLM1 NM1 OPM1 CAPM1 CLM2 NM2 OPM2 CAPM2

ANT COM STRT

STPD

STOP COM PH1 PH2

EDG1

COM 24VA FLS

EDG2

67411385

25

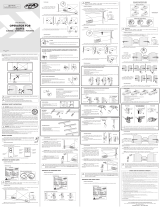

CONNECTIONS

WARNING: The control unit is designed with the automatic detection of not used N.C. inputs (Photocells, Stop and Limit

switch) except the SAFETY EDGE input. The exclude inputs in self-programming can be restored in the “Check inputs”

menu without need to repeat the programming (page 38).

Limit Switch opening M1

Limit Switch closing M1

Limit Switch opening M2

Limit Switch closing M2

Common

Motor 1

opening

Motor 1

closing

Motor 1

Neutral

Capacitor

Motor 1

Motor 2

opening

Motor 2

closing

Motor 2

Neutral

Capacitor

Motor 2

Start

Stop

Common

Antenna

START Pedestrian

Common

Photocell 1

Safety edge 1

Photocell 2

Safety edge 2

The herein reported

functions are

available starting

from revision 33, on

R1B versions only.

Optional

Obligatory jumper

without accessory

connection.

Common

Lamp

(500mA max)

AUX

(24V 800mA

max)

Rev.07 - 12/2014

67411385

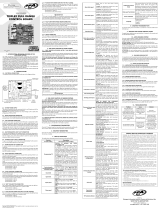

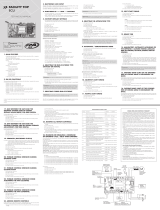

UPDOWN

ALL OTHER PARAMETERS HAVE DEFAULT SETTINGS WHICH ARE USEFUL FOR THE 90% OF THE APPLICATIONS

BUT CAN BE HOWEVER SET THROUGH THE SPECIAL MENU. FOR ENTERING INTO THE SPECIAL MENU MOVE

ON ONE OF THE MENU AND PRESS THE UP AND DOWN BUTTONS AT THE SAME TIME FOR 5 S.

26

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

OK

1

2

3

4

5

6

7

8

OK

OK

OK

OK

OK OK

OK OK

OK OK

OK OK

OK OK

UP

UP

UP

UP

UP

UP

UP

OK

PRESS

BUTTON

STORED

TRANSMITTERS

START

MOTOR

ONE SINGLE

LEAF

LOGIC

PAUSE TIME

START IN

PAUSE

PROGRAM-

MING

TEST START

MENU

SEA

SET

MENU

SEA

SET

OK

UP

LANGUAGE

ITALIANO

UP

PROGRAMMING

BUTTONS

OK

DOWNUP

9

Skip this step if you do not want to program a transmitter

Press the

button of the

TX to be

stored

OK to exit

Menu or press

the button of

the next TX to

be stored

Choose the type of

motor with

UP or DOWN

To confirm and return

to main menu

With UP or DOWN

choose

the desired logic

To confirm and return

to main menu

With UP or DOWN

choose a delay for

automatic closing

To confirm and return

to main menu

Skip this step

if you want to work

in half-automatic

logic

With UP or DOWN

Choose ON

To confirm and return

to main menu

With UP or DOWN choose ON

to start times learning

At the end of the selflearning

the control unit returns automatically

to the main menu

With

UP or DOWN Choose

ON to start test

To confirm and return to

main menu

Skip this step if a TX has already been stored

With UP or DOWN choose

ON only if in single

leaf mode (Motor 1)

To confirm and return

to the main menu

Skip this step if you are working in double leaf mode

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

MENU

SEA

SET

RECEIVER

MISSING

If on the display

appears the item:

Check if a receiver has

been connceted

(see page 24)

(See

page 27)

The gate will execute a CLOSING-OPENING-CLOSING CYCLE

(See

page 27)

PROGRAMMING

QUICK START

Rev.07 - 12/2014

67411385

27

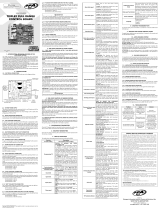

MENU

Default

1 - langvage

4 - one s ngle

leaf *

SET

espanol

engl sk

fran(a s

tal ano

stop

start

off

on

off

1 240

Start

Stop

start

off

off

tal ano

kydravli(

E(kan (

U

Sliding

Reversible sliding gate

Hydraulic

Mechanic

off

7 - start n pavse

on

Off on

off

off

vnlo(k

Storing of a command

for unlocking an

electric brake

MENU FUNCTIONS TABLE GATE 2 DG R1

Description

Set value

Italian

English

French

Spanish

U

2 - trans tters

External odvle

U

Pedestr an Start

(Lear e ory

UU

Delete a trans itter

U

Ped Start.

External module

Pedestrian Start

Delete single transmitter

Delete transmitter memory

3 - otor

U

Sl d ng

Reuers ble Sl d ng gate

E(kan (

U

Disabled

In ON activates single leaf

mode (Motor 1)

5 - log (

Avto at (

U

open-stop-(lose-stop-open

2 bvttons

safety

Dead an

U

open-stop-(lose-open

Automatic

Step by step type 1

Step by step type 2

Two buttons

Safety

Dead man

Avto at (

U

6 - paVse t e

U

Setting from 1s to 4min.

OFF

(semi-automatic logics)

8 - progra ng

U U

Times learning start

In pause start is not acceped

In pause start is accepted

Note 1: The * indicates that the default value or the menu may change depending on the selected motor

type.

dut(k

Olandese

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

(See page 29)

Off on

off

9 - test start

end

Start command

Select END and press OK to exit the menu.The menu

deactivates automatically after 2 minutes

(See page 28)

Rev.07 - 12/2014

The control unit is pre-set with the default settings, to start the control unit with the

DEFAULT settings just keep pressed the UP and DOWN buttons at the same time power

supplying the control unit the display shows the message init.

The DEFAULT settings are shown in the Menues table.

SELFLEARNING OPERATION TIME WITH AMPEROMETRIC SENSOR

(For electromechanical motors only)

The times learning can be done only on electromechanical gates, taking advantage of the automatic detection of

the stops.

Once the programming has been started just make sure that the gate executes the following cycle: CLOSING M2

- CLOSING M1 - OPENING M1 - OPENING M2 - CLOSING M2 - CLOSING M1.

Note: For stop detection sensitivity setting refer to the special menu.

LEARNING WITH LIMIT SWITCH

When limit switches are mounted, the gate executes automatically the follwing cycle: CLOSING M2 - CLOSING M1 -

OPENING M1 - OPENING M2 - CLOSING M2 - CLOSING M1.

Before starting the learning, make sure( through the test menu), that the relative limit switches of every leaf and every

opening are employed.

Exe: For the M2 motor closing the limit switch M2 in closing must be employed.

67411385

WORKING TIMES SELFLEARNING THROUGH IMPULSES

ATTENTION: This procedure is potentially dangerous and should only be performed by qualified people in

safety conditions.

NOTE: The card is preset with the standard working times, therefore the automation can be started even

without the times programming, simply by adjusting the timing on the display (see default times).

1) Turn off electricity, release the motors and manually position the leaves on halfway.

Reset the mechanical lock.

2) Connect the control board to the power supply

3) Select on the on-board display or JOLLY programmer, the type of motor that you are using as indicated in the

dispaly management ( E(kani( - Ele(trokydravli(, etc).

4) If necessary also set the operation logic and the other parameters. If you want to program with a transmitter, store

a transmitter before programming.

5) Select PROGra ing on the display, press OK and than one of the UP or DOWN buttons.

(If the motor starts in opening, remove and re-put power supply, select on the display reuerse otor. And through

the UP and DOWN button put it on ON, or if you have the Jolly programmer, activate the motor exchange function. )

6) At this point the gate will start the following cycle: CLOSING M2 - CLOSING M1 - OPENING M1 - OPENING M2 -

CLOSING M2 - CLOSING M1. During cycle, to store the respective stops, press UP or DOWN or START at every

point of stop of the leaf.

7) The self-learning is done.

U

UU

U

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

WORKING TIMES SELF LEARNING

28

SELFLERNING OPERATION TIME WITH ENCODER / POTENTIOMETER

When an encoder is installed, it is necessary to select On in the EN(oder menu, when the potentiometer is installed, it

is necessary to select POTENtio eter in the EN(oder menu. Start programming and make sure that leaf 2 starts as

first in closing. The gate will automatically execute the following cycle: CLOSING M2 - CLOSING M1 - OPENING M1

- OPENING M2 - CLOSING M2 - CLOSING M1.

Note: For stop detection sensitivity setting refer to the special menu.

U

Rev.07 - 12/2014

FUNCTION LOGIC

AUTOMATIC LOGIC

A start impulse opens the gate. A second impluse during the opening will not be accepted.

A start impulse during closing reverses the movement.

SECURITY LOGIC

A start impulse opens the gate. A second impulse during opening reverses the movement.

A start impulse during closing reverses the movement.

STEP BY STEP TYPE 1 LOGIC

The start impulse follows the OPEN-STOP-CLOSE-STOP-OPEN logic.

STEP BY STEP TYPE 2 LOGIC

The start impulse follows the OPEN-STOP-CLOSE -OPEN logic.

DEAD MAN LOGIC

The gate opens as long as the START button of opening is pressed; releasing it the gate stops. The gate closes as

long as the button connected to the PEDESTRIAN START is pressed; releasing it the gate stops. To execute

complete opening and/or closing cycles the related pushbuttons must be constantly pressed.

2 PUSHBUTTONS LOGIC

One start opens, one pedestrian start closes. In opening the closing will not be accepted. In closing a start command

reopens, a pedestrian start command (closes) will be ignored.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will be semi-

automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU the item

Startin pavse and choosing ON or OFF. By default, the parameter is OFF.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will be semi-

automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU the item

Startin pavse and choosing ON or OFF. By default, the parameter is OFF.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will be semi-

automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU the item

Startin pavse and choosing ON or OFF. By default, the parameter is OFF.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will be semi-

automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU the item

Startin pavse and choosing ON or OFF. By default, the parameter is OFF.

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

67411385

29

Rev.07 - 12/2014

67411385

30

PRESS AT THE SAME TIME FOR 5 SECONDS TO ENTER OR TO EXIT THE SPECIAL MENU

MENU SP

Default

SET

10 100

10 100

0.0 5.0

Pre-flashing only

active before closing

75

Off

75

10 100

10 100

75

75

Off 6

2,5

1,5

Off 20

6 - leaf delay n (los ng *

7 - Pvshouer *

Off

Only (los ng

Off

8 - pvsk ng stroke

Off 3

Off 50

20

Off 50

20

Off 50

20

Off 50

20

bvzzer

Buzzer

15 - reuerse otor *

U

Off

On

Off

Off

UPDOWN

SPECIAL MENU FUNCTIONS TABLE GATE 2 DG R1

UP and DOWN

press END or

UP and DOWN

For entering into the special menu move on one of the menu and press the

buttons at the same time for 5 s. For exiting the special menu move on one of the

menu and press the buttons at the same time for 5 s.

Description

Set value

1 - open ng torq 1 *

2 - (los ng torq 1 *

3 - open ng torq 2 *

4 - (los ng torq 2 *

M1 opening torque

Note: with hydraulic motors

the torque will be on 100%

M2 opening torque

Note: with hydraulic motors

the torque will be on 100%

M2 closing torque

Note: with hydraulic motors

the torque will be on 100%

M1 closing torque

Note: with hydraulic motors

the torque will be on 100%

5 - leaf delay n open ng *

Setting from OFF to

6 seconds

Setting from OFF to

20 seconds

Open ng and (los ng

Only open ng

Disabled

Opening an closing

Opening only

Closing only

From OFF to 3 seconds

10 - (los ng sloudoun 1

9 - open ng sloudoun 1

12 - (los ng sloudoun 2 *

11 - open ng sloudoun 2 *

From OFF to 50% of

the stroke

From OFF to 50% of

the stroke

From OFF to 50% of

the stroke

From OFF to 50% of

the stroke

13 - preflasx ng

14 - flasx ng l gxt

Only (los ng

Nor al

U

L gxt

aluays

Normal

Control lamp

Always ON

Pre-flashing time

Synchronized right motor

Synchronized left motor

Nor al

U

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

SPECIAL MENU

Rev.07 - 12/2014

MENU SP

Default

SET

Description

Set value

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

OFF

ON

Off

Off

16 - EN(ODER *

xxx.s

Xxx.

xxx.s

Xxx.

16 - EN(ODER *

17 - opening ti e

otor 1

u

u

18 - (losing ti e

otor 1

u

u

xxx.s

xxx.s

Xxx.

Xxx.

In ON enables the

Encoder.

19 - opening ti e

otor 2

u

u

20 - (losing ti e

otor 2

u

u

17 - en(oder tot.

Otor 1

u

18 - en(oder par.

Otor 1

u

19 - en(oder tot.

Otor 2

u

20 - en(oder par.

Otor 2

u

In OFF disabled the

Encoder

Indicates the working times selflearning

in opening and closing on motor 1.

With UP or DOWN it is possible to increase

or reduce the working times.

Indicates the working times selflearning

in opening and closing on motor 2.

With UP or DOWN it is possible to increase

or reduce the working times.

Encoder impulses stored in programming

on motor 1.

Encoder impulses during operation

on motor 1.

Encoder impulses stored in programming

on motor 2.

Encoder impulses during operation

on motor 2.

67411385

31

Off

16 - EN(ODER *

Enables the reading of

the potentiometer with

LE card.

Potentio eter

u

Reports the current posi-

tion of the potentiometer

on the leaf of motor 1.

This parameter is useful

for seeing if the potentio-

meter is read correctly.

--------

Reports the impulses

stored by the control unit

when the leaf of motor 1

is fully open.

--------

--------

--------

--------

--------

Reports the impulses

stored by the control unit

when the leaf of motor 1

is fully close.

Reports the current posi-

tion of the potentiometer

on the leaf of motor 2.

This parameter is useful

for seeing if the potentio-

meter is read correctly.

Reports the impulses

stored by the control unit

when the leaf of motor 2

is fully open.

Reports the impulses

stored by the control unit

when the leaf of motor 2

is fully close.

21 - i.par. 1 *

u

22 - i.ap. 1 *

u

23 - i.(h. 1 *

u

24 - i.par. 2 *

u

25 - i.ap. 2 *

u

26 - i.(h. 2 *

u

Rev.07 - 12/2014

MENU SP

Default

SET

Description

Set value

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

1 240

20

Off on

Off

5 100

100

0 10e9 0

1 240

100 10e4

0 100

100%

10e4

= start

Off

= start

27 - (ourtesy l gxt

N (y(le

Courtesy light setting

from 1s to 4min.

Courtesy light in cycle

28 - traff ( l gxt

reseruat on

When setting this function

the pedestrian input will be

activated to work on the

auxiliary board SEM

(traffic light management).

29 - pedestr an open ng

Setting from 5 to 100

30 - pedestr an PAvSE

31 - a((elerat on

32 - a ntenan(e (y(les

U

33 - perfor ed (y(les

U

Pause in pedestrian

opening same as in

total opening

Disabled

Acceleration ramp

Setting from 1s to 4 min.

Setting from 100 to

100000

Reports the executed

cycles. Keep pressed OK

to reset the cycles

34 - t er

U

off

off

ON PXOTO2

Disabled

Timer function active

on photocell 2

ON PEDESTR AN ENTRY

Timer function active on

pedestrian input

Active in opening

and closing

35 - EDGE1

ONLY (LOS NG

OPEN NG AND (LOS NG

ONLY OPEN NG

Active only in opening

Active only in closing

OPEN NG

AND

(LOS NG

36 - EDGE2

37 - EDGE1

8x2

38 - EDGE2

8x2

ONLY (LOS NG

OPEN NG AND (LOS NG

ONLY OPEN NG

Active in opening

and closing

Active only in opening

Active only in closing

OPEN NG

AND

(LOS NG

Nor al

U

Nor al

U

Edge is active and

protected by a 8k2 resistor

Normal N.C. contact

Edge is active and

protected by a 8k2 resistor

Normal N.C. contact

Nor al

U

Nor al

U

Rev.07 - 12/2014 67411385

32

stop

39 - PKOTO1

40 - PKOTO2

MENU SP

Default

SET

Description

Set value

OPEN NG AND (LOS NG

(LOS NG

Stop AND (LOSE

(LOSE

PAUSE RELOAD

Active in opening

and closing

Photocell active in closing

Photocell active before

opening

The photocell gives a

command to close during

opening, pause and

closing

The photocell charging the

pausing time

The photocell stops in closing

and closes when released

stop

OPEN NG AND (LOS NG

(LOS NG

Stop AND (LOSE

(LOSE

PAUSE RELOAD

Active in opening

and closing

Photocell active in closing

Photocell active before

opening

The photocell gives a

command to close during

opening, pause and

closing

The photocell charging the

pausing time

The photocell stops in closing

and closes when released

(LOS NG

OPEN NG

If the photocell is occupied

during opening, pause or

closing, the gate reopens

completely and closes

without observing the

pause time.

Delay pause ti e

u

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Delay pause ti e

u

If the photocell is occupied

during opening, pause or

closing, the gate reopens

completely and closes

without observing the

pause time.

67411385

41 - 24u avx

ALUAYS

N (Y(LE

N pavsE

OPEN NG

(LOS NG

AUX output always

power supplied

AUX output power

supplied only during opening

AUX output power

supplied only during closing

AUX output power

supplied only during pause

AUX output active only

during cycle

POS T UE BRAKE

ANAGE ENT

UU

NEGAT UE BRAKE

ANAGE ENT

U

U

Positive Electrobrake

Negative Electrobrake

ALUAYS

1 flash per sec. in opening

2 flashes per sec. in closing

Steady lit in Stop or Open.

Gate open uorning

light

Rev.07 - 12/2014

33

0 20

1

42 - opening POSiTiON

RE(OUERY *

Recovers the motor inertia

in opening after stop or

inversion.

0.1

44 - OTOR RELEASE *

U

Off

0.1 3.0

45 - BRAKE *

----

Disabled

Setting from 1 to 3

Adjusts the braking on the

limit switches

0

MENU SP

Default

SET

Description

Set value

off 8

46 - PER OD (AL pvshouer *

off

Off

Off

3

Off 5

49 - lock

off

Off

On

51 - ant ouerlap *

Off

On

Desactivate the leaves

anti-overlapping control,

allowing separate control

of the two leaves.

Activate the leaves

anti-overlapping control

off

Allows the repetition of the

Pushover functionat a

distance of time adjustable

from 0 to 8 hours at hourly

intervals

47 - ant ntrvs on

ONLY (LOS NG

ONLY OPEN NG

OPEN NG AND (LOS NG

Only on limit switch in opening

Only on limit switch in closing

On limit switches in closing

and in opening

If the limit switch is freed

manually it forces the

reclosing of the gate

48 - LOCK T E

U

Sets the lock release

time from 0 to 5 s

ONLY (LOS NG

ONLY OPEN NG

OPEN NG AND (LOS NG

Active only before opening

Active before opening

and closing

Active only before cloning

OPEN NG

The flashing light remains

ON with active timer and

open gate

The flashing light remains

OFF with the active timer

and open gate

50 - FLASX NG L GXT AND

t er

U

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

67411385

0 20

1

43 - (losing POSiTiON

RE(OUERY *

Recovers the motor inertia

in closing after stop or

inversion.

1 10

Shows last event

(See alarms table)

52 - diagnosti(S

53 - sloudoun ra p torq

U

100

Adjusts the transition

between max. torque

and slowdown

0 %

100%

Rev.07 - 12/2014

34

55 - edge AVTOTEST

edge1

edge2

edge1-2

Off

edge1-2

Test enabled on edge

1 and 2

Test enabled on edge 1

Test enabled on edge 2

Disabled

MENU SP

Default

SET

Description

Set value

0

0 100

0

0 100

Adjust the tolerance

between stop and

obstacle Motor 1 opening.

0

0 100

0

0 100

off

off

off

off

off

64 - slou doun

sens t u ty *

56 - OPEN NG TOLERAN(E

otor1

U

57 - (los ng TOLERAN(E

otor1

U

58 - OPEN NG TOLERAN(E

otor2 *

U

59 - (los ng TOLERAN(E

otor2 *

U

60 - open ng sens t u ty

otor1

U

61 - (los ng sens t u ty

otor1

U

62 - open ng sens t u ty

otor2 *

U

63 - (los ng sens t u ty

otor2 *

U

Disabled

Adjusts the intervention time

of the Encoder / Potentiometer

on Motor 1 in opening

Disabled

Disabled

Adjusts the amperometric

sensitivity in slowdown.

Active only if the motors

are electromechanical.

Disabled

Adjust the tolerance

between stop and

obstacle Motor 2 opening.

Adjust the tolerance

between stop and

obstacle Motor 1 closing.

Adjust the tolerance

between stop and

obstacle Motor 2 closing.

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

54 - fototest

photo1

photo2

photo1-2

Off

Off

Auto-test active only on

Photo1

Auto-test active only on

Photo2

Auto-test active on

Photo1 and Photo2

Disabled

67411385

10% (max) 99% (min)

Off (Intervention excluded)

10% (Fast intervention)

99% (Slow intervention)

10% (Fast intervention)

99% (Slow intervention)

10% (Fast intervention)

99% (Slow intervention)

Off (Intervention excluded)

Off (Intervention excluded)

off

Disabled

Off (Intervention excluded)

10% (Fast intervention)

99% (Slow intervention)

Adjusts the intervention time

of the Encoder / Potentiometer

on Motor 1 in closing

Adjusts the intervention time

of the Encoder / Potentiometer

on Motor 2 in opening

Adjusts the intervention time

of the Encoder / Potentiometer

on Motor 2 in closing

Rev.07 - 12/2014

35

MENU SP

Default

SET

Description

Set value

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Avto at (

U

Limit switch in automatic

recognition

Only limit switch in

opening present

ONLY (LOS NG

Avto at (

U

73 - sELE(T L T SU T(K

U

ONLY OPEN NG

Only limit switch in

closing present

To be activated if there is

a limit switch that stops

the motor phase.

75 - passuord

---- ----

Allows the entering of a

password blocking the

control unit parameters

modification.

END

Select END and press OK to exit the special menu.

The special menu switches off automatically after 20 minutes.

Otor internal

U

If limit switches are present

it adds an extra time to the

movement of the motors

after the reading of the limit

switches.

74 - ektra ti e

U

0.0 s 10 s

0.0 s

67411385

69 - pot. Slovdoun

threshold opening1 *

Adjust the threshold of the

potentiometer in slowdown.

By default this value is set

on 1 and can be increased

manually up to the

maximum value read on

the DEBUG VPI, VP2

menu.

65 - pot. threshold

opening 1 *

Adjusts the threshold of the

potentiometer intervention.

The parameter self-

determines in learning but

can also be adjusted later.

The lower the value, the

slower will be the response

of the potentiometer.

The parameter can be set

as maximum threshold at

the value read on the

DEBUG VPI, VP2 menu.

66 - pot. threshold

(losing 1 *

1 100

1 10

67 - pot. threshold

opening 2 *

68 - pot. threshold

(losing 2 *

70 - pot. Slovdoun

threshold (losing1 *

71 - pot. Slovdoun

threshold opening 2 *

72 - pot. Slovdoun

threshold (losing 2 *

Note 1: The * indicates that the default value or the menu may change depending on the selected motor type.

Note 2: After initialization the parameters "motor type" and "limit switch type" remain son the value chosen in the

setup program.

Rev.07 - 12/2014

36

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

PASSWORD ENTERING MANAGEMENT

With a new control unit all menus can be displayed and set and the password will be disabled.

Selecting one of the Menus and keeping UP and DOWN pressed at the same time for 5 seconds, you will access the SP Menu

containing the Passuord Submenu.

Pressing OK in the Passuord Menu, you will proceed with the entering of the numeric code of the 4-digit PASSWORD.

Use UP and DOWN to increase or decrease the number, press OK to confirm it and you will pass automatically to the entering of

the next number. Pressing OK after the last entered number the word SvRE? appears, confirm the activation of the PASSWORD

and the message Ok appears, pressing UP or DOWN instead you can cancel the operation and NO OPERATION will appear on the

display.

Once entered the PASSWORD, it will be definitively activated, once the display switch off timeout has expired, or by turning off

and on again the control unit. Once the PASSWORD has been activated, the menus of the display can be only displayed but not

set. To unlock them you must enter the correct PASSWORD in the Passuord menu, if the password is wrong the message ERRor

will appear.

At this point, if the password has been entered correctly, the menus will be unlocked and it will be possible to change the

parameters of the control unit again.

If the control unit has been unlocked through Passuord Menu, it is possible to enter a new and different password, using the

same entering process as for the first one; at this point, the old password will no longer be valid.

If the password has been forgotten, the only way to unlock the control unit is to contact the SEA technical assistance, which will

assess whether to provide the procedure to unlock the control unit or not.

Note: The password cannot be set through the Jolly or Jolly 2 terminal.

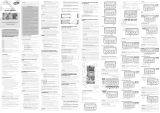

POTENTIOMETER MANAGEMENT (Position Gate)

(Available only on GATE 2 DG R1B)

1 2

ON

CN1

CNP

DS1

POTENC

M2

M1

1 2 4

P01 D1 P11 P02 D2 P12 I1

5 6 7

I2

GND

I3 I4

3 8 9 10 11

+ -

LE CARD

Potentiometer 1 (Position Gate)

Potentiometer 2 (Position Gate)

D2 (White)

P02 (Green)

P12 (Brown)

D1 (White)

P01 (Green)

P11 (Brown)

To connect the potentiometer you must use the LE card (Cod.23001256) and set with Dip Switches 1 and 2 both in OFF.

With the potentiometer it is possible to access the hidden DEBUG menu to check the maximum settable value as threshold in

normal and slowdown speed.

To access this menu you have to press, in the menu that displays the firmware version, UP and OK at the same time until the

menus VP1 speed of potentiometer 1 and VP2 speed of potentiometer 2 will appear.

To view the speed of the potentiometer on the related menu, press OK.

To exit the DEBUG menu go to END and press OK.

If the reading of the potentiometer is reversed relative to the movement of the motor, on the display will appear the alarm

"Potentiometer direction" and you will have to reverse the brown wire with the green one and repeat programming.

Rev.07 - 12/2014 67411385

37

67411385

MENU

SEA

SET

---

----

----

DISPLAY INPUT STATUS

When the segment is

ON during self-

learning, the input

status is closed or

OFF.

Start

Start

pedestrian

Stop

Limit

Switch

opening

motor 1

Photocell 1

Photocell 2

Edge 1 Edge 2

Limit

Switch

closing

motor 1

Limit Switch

opening motor 2

Limit Switch

closing motor 2

Initial system

Software Version

Programming example

u.022

UP

OK

UP

UP

UP

DOWN

DOWN

DOWN

OK

OK

OK

DOWN

ELE(T

otOR

U

E(ka

U

Sl d

The settings of the control unit are made through the UP, DOWN and OK buttons. The UP and DOWN buttons to scroll through the MENUS and

SUBMENUS. By pressing OK you enter from MENU into SUBMENU and confirm the choice.

Moving in the language menu pressing the UP and DOWN buttons at the same time you access the SP MENU for special settings.

Moving in the language menu pressing the OK button for 5 seconds, you enter the CHECK MENU, where you can check the operating status of

all inputs.

L T SU T(H

(LOS NG 1

U

L T SU T(H

OPEN NG 1

U

MENU

start

Description

Description

EDGE1

PHOTO1

PHOTO2

PedESTR AN Start

END

Start test

Stop test

Pedestrian

start test

Safety edge1

test

Photocell 1

test

Photocell 2

test

M1 Opening

limit switch

test

M1 Closing

limit switch

test

The contact must be a N.O. Contact . When activating the related command

on the display SET lights up, the input works.

If SET is always on, check the wirings.

The contact must be a N.C. Contact. When activating the related command

on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

The contact must be a N.C. Contact. When activating the related command

on the display SET lights up, the input works. If SET is always on, make

sure that the contact is a N.C. contact or that the related limit switch is not occupied.

The contact must be a N.O. Contact. When activating the related command

on the display SET lights up, the input works.

If SET is always on, check the wirings.

The contact must be a N.C. Contact. When activating the related command

on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

IThe contact must be a N.C. Contact. When activating the related command

on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

The contact must be a N.C. Contact. When activating the related command

on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

The contact must be a N.C. Contact. When activating the related command

on the display SET lights up, the input works. If SET is always on, make

sure that the contact is a N.C. Contact or that the related limit switch is not occupied.

Exit menu

stop

OK

OK

OK

MENU FUNCTION TABLE CHECK GATE 2 DG R1 INPUTS

To access the Menu for input check keep pressed OK for about 5 seconds.

enabled

blo(ked

enabled

blo(ked

enabled

blo(ked

OK

enabled

blo(ked

EDGE2

Safety edge2

test

The contact must be a N.C. Contact. When activating the related command

on the display SET lights up, the input works.

If SET is always on, make sure that the contact is a N.C. Contact

OK

enabled

blo(ked

L T SU T(H

(LOS NG 2

U

L T SU T(H

OPEN NG 2

U

M2 Opening

limit switch

test

M2 Closing

limit switch

test

The contact must be a N.C. Contact. When activating the related command

on the display SET lights up, the input works. If SET is always on, make

sure that the contact is a N.C. contact or that the related limit switch is not occupied.

The contact must be a N.C. Contact. When activating the related command

on the display SET lights up, the input works. If SET is always on, make

sure that the contact is a N.C. Contact or that the related limit switch is not occupied.

Note: If the Stop, Photocell 1 and Photocell 2, Edge 1 and Enge 2 contacts are not bridged in self-learning, they will be deactivated and

can be reactivated through this menu, without repeating times self-learning.

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

MENU FOR INPUT CHECK

38

Rev.07 - 12/2014

67411385

39

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

RADIO TRANSMITTER SELF LEARNING

WITH RECEIVER ON BOARD OF CONTROL UNIT

!!

ROLLING CODE:

press twice

1 2 3 4

0

1

2

3

4

5

TABLE EXAMPLE

Transmitter

button

Memory

location

Serial number Customer

WARNING: Make the radio transmitters programming before you connect the antenna and insert the receiver into the

special CMR connector (if available) with turned off control unit.

With RF UNI module it will be possible to use both Coccinella Roll Plus transmitters, max. 800 codes (buttons), and radio

transmitters with fixed code, max. 100 codes (buttons). The first memorized radio transmitter will determine the type of the

remaining radio transmitters.

If the receiver is a Rolling Code, press twice the button of the radio transmitter that you want to program to memorize the first TX.

Notes:

- Enter radio transmitters learning only when the working cycle stops and the gate is closed.

- You can store max. 2 of the available 4 functions. If the control unit receives a code which was already associated to another function it will be

updated with the new function.

In the case of transmitters with fixed code it is necessary to press 1 time the button of the transmitter you want to program to store the first

remote control

FIXED CODE:

press once

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

SET

START

PEDESTRIAN

START

EXTERNAL

MODULE

STOP

DELETE A

TRANSMITTER

0

OK? OK

CLEAR

MEMORY

OK

PRESS

BUTTON

STORED

STORED

STORED

STORED

PRESS

BUTTON

PRESS

BUTTON

PRESS

BUTTON

If you want to program

the pedestrian

start as second

channel.

If you want to

delete a single

transmitter.

If you want to delete

the whole memory

If you want to program

the activation

of the LIGHT

output

as second channel.

Press the

button of the

transmitter

to be stored

Press the

button of the

transmitter

to be stored

Press the

button of the

transmitter

to be stored

Select with

UP or DOWN

the memory

location

to be deleted

and press OK

Press the

button of the

transmitter

to be stored

If you do not want to execute the cancellation,

press UP or DOWN to return to the

TRANSMITTER menu.

Confirm the cancellation.

If you want to

program the

UNLOCH as

second channel.

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

UNLOCH

STORED

PRESS

BUTTON

Press the

button of the

transmitter

to be stored

If you want to

program the

STOP as

second channel.

OK

OK

OK

OK

OK

OK

OK

for 10 s.

MENU

SEA

SET

OK

TRANSMITTERS

OK

Rev.07 - 12/2014

Photocell 1 and Photocell 2 Connections

Note: If the photocells are not connected, it is not necessary put a jumper between the clamps

(6 and 7 and/ou 6 and 8 of the CN1 terminal)

24VA = AUX 24V (Accessories) 800 mA max COM = 0V PH1 = Photocell contact 1

PH2 = Photocell contact 2

Note: For the autotest in the fototest menu select the photocell or the photocells on which you want

to perform it. Auto-test is possible only when the transmitter of the photocell is powered on 24V~.

The default setting of the photocell 1 is FOTO CLOSE and the one of the photocell 2 is FOTO OPEN.

The photocell 2 can also be set as TIMER (see TIMER function).

TIMER

Options AUX 24V 800 mA max can be set with on-board

Display or with Jolly device.

It is possible to chose when having tension on the AUX output.

The options are: always, only during opening, only during

cycle, only before opening or only during pause or for the

management of the positive or negative electrobrake.

N.B: For the autotest connect

the transmitters to the

contacts 20 and 21, if you do

not want the autotest connect

the transmitters to the

contacts 19 and 20.

67411385

START - STOP - PEDESTRIAN START - ANTENNA -

PHOTOCELL

PEDESTRIAN START (N.O.) The pedestrian start can be connected

between the conectors 2 and 4 of the CN1 terminal .

This input allows a partial opening, the opening space can be set through

the on-board display or through the JOLLY device.

Note1: The contact for partial opening is a N.O. Contact (Normally open).

Holding START starts the TIMER function, releasing the pedestrian start,

the operator repeats the pause and then performs the closing. In the case

of triggering a safety device the timer will automatically reset after 6

seconds.

Note2:In 2 BUTTONS logic it is necessary to keep pressed the Start Ped.

to re-close the automation.

Note3: In deadman logic this button executes the re-closing if you keep it

pressed.

Note4: When closed during pause, the gate will reclose only after this

input has been reopened.

TIMER activation: This input can be transformed into TIMER (See

TIMER).

START (N.O.) The

An impulse given to this contact opens and closes the automation depending on the selected logic, it can be given by a keyswitch, a keypad, etc.

To connect the other devices refer to the related instructions leaflets. (ie. loop detectors and proximity switches).

Note1: In DEADMAN logic keep pressed the Start for the opening of the automation.

Note2:

START is connected between connector 2 and 3 of the CN 1 terminal.

In the case of triggering a safety device

the timer will automatically reset after 6 seconds.

Holding START starts the TIMER function, releasing the start, the operator repeats the pause and then performs the closing.

In 2 BUTTONS logic this button performs the opening.

STOP (N.C.) The STOP is connected between the clamps 2 and 5 of the CN1 terminal .

When pressing this button the motor immediately stops in any condition/position. To re-start the movement give a start command.

After a stop the motor always re-starts in closing.

Can be activated through the on-board display or through the Jolly programmer. In both cases it’s a N.O. contact which provoques the

opening of the automation keeping it open as long as it is activated. When it’s released, after having paused for the set pausing time the

gate recloses. The TIMER can be activated on the inputs FOTO2, PEDESTRIAN START or keeping busy the START input.

Note1: When activated on the pedestrian entry, the pedestrian will be OFF also on the radio transmitter.

Note2: In the event of an intervention of a security device during the timer (Stop, amperometric, Edge), a start impulse restors the

movement.

Note3: In case of no power supply with open gate and active Timer the control unit will restore its function, otherwise if during restoring of

the power supply the TIMER is not activated it will be necessary to give a start impulse for the reclosing.

10 11 12 13

1 2 3 4 5 6 7 8 9

-

3

6

5

6

4

START

PEDESTRIAN

START

STOP

C

CN2

RX1

RX2

TX1

TX2

6

7

6

8

14 15 16 17 18 19 20 21 22 23

14 15 16 17 18 19 20 21 22 23

20

21

19

20

19

20

20

21

CN2

CN1

OPTIONS ON FOTO1 and FOTO2 adjustable on on- board display or with JOLLY

terminal.

FOTO CLOSE activation ((losing): if occupied, reverses the movement in closing,

during pause it prevent the closing.

Activation repeat pause (pavse RELOAD): If occupied, during pause it recharges the

timer of pause. In closing it reverses the movement.

FOTO OPEN activation (oPEning): If activated the photocell blocks the movement as

long as it’s busy, when released the opening continues.

FOTO PARK activation (stop and (lose): in opening it is not active; in pause are

activated it commands the closing when released, otherwise it’s not active; in closing it

stops the movement as long as it is busy, when released the closing continues.

FOTO STOP activation (STOP): When activated before the opening the photocell

blocks the automation as long as it is busy, during the opening it will be ignored. In

closing the intervention of the photocell causes the reopening.

Activation PHOTO CLOSE IMMEDIATELY ((lose): The photocell stops the gate as

long as it is occupied in both opening and closing, when released it gives a closing

command (Closing one second after release of the photocell ).

Activation delay pause TI E: If the photocell is occupied during opening, pause or

closing, the gate reopens completely and closes without observing the pause time.

U

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

40

Rev.07 - 12/2014

67411385

SAFETY EDGE AND FLASHING LAMP

SAFETY EDGE

Two safety edges (EDG1 e EDG2) can be connected, respectively between the contacts 9, 11 and 10 and 11 of CN1.

Pressing EDG1 and EDG2, the contact opens, causing a partial reversing of the gate in closing and opening.

Note1: Put a jumper between the not used N.C. Contacts. The EDG1 and EDG2

inputs can be set: only in closing, only in opening or in both directions.

Note2: It is possible to activate a balanced edge 8K2 through the on board

display or through the Jolly programmer, in such case the edge contact will be

controled by a specific resistance value, detecting the possible involontary short

circuit of the device. In case of an imbalanced device a special alarm will show on

the on board display or on the JOLLY programmer.

If you connect a wireless edge it is possible to make a self-test on the power

supply of the receiver by connecting it to 24Vac and selecting in the Edge

avtotest menu the edge or the edges on which to perform the test.

SAFETY GATE

The Safety Gate, unlike the amperometric sensor, can be used both on

electromechanical and hydraulic operators.

The Safety Gate is an ENCODER allowing the detection of the gate position

and its reversing in case of obstacles. To use the ENCODER it is necessary

to enable it inside the special EN(oder Menu. The sensitivity on the obstacle is

adjustable from 0 - 99%. The higher the percentage is the more it will be

difficult to detect the obstacle.

AMPEROMETRIC DEVICE FOR ELECTROMECHANICAL OPERATORS

This control unit comes with an obstacle detection system working only on electromechanical operators allowing to

have the reversing on obstacles and the automatic detection of the stops.

Sensitivity adjustable from off to 99% inside the special menu. The more the percentage is high the more the

obstacle detection will be difficult. On hydraulic unit this parameter will be always OFF.

SAFETY GATE OR AMPEROMETRIC MANAGEMENT

ATTENTION: The first

operation after power failure, will

be executed with the set speed

to search the mechanical stops

limit.

SAFETY GATE 1

1

3

4

1

3

4

SAFETY GATE 2

1

2

3 4

ENC1+24V ENC2 GND

CN7

2

24V Flashing light 3W Max

The flashing light can be connected between the FLS and COM

connectors from Cn1 (It is recomended to use a 24V Flash Led

flashing light).

It blinks once per second during opening and twice per second during

closing, while it remains lit during pause.

Throught the warning light it is also possible to identify alarm signals comming from the STOP, PHOTOCELL 1,

PHOTOCELL2 and EDGE devices. Through the on board display or the Jolly programmer it is possible to activate the pre -

flashing function and/or to modify the flashing light function choosing between fixed flashing, control lamp or Buzzer.

The pre-flashing can be set from 0 to 5 s. or it is possible to have it only before closing.

COURTESY LIGHT

Timing

from 0 to 4 min

(230V~ 50W Max - 115V~ 50W Max)

CN5

34 35

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

10 11 12 13

1 2 3 4 5 6 7 8 9

CN1

9

11

10

11

13

11

FLS

Common

41

EDG2 Safety edge

in opening

EDG1 Safety edge

in closing

Rev.07 - 12/2014

Example

Motor 2

Motor 1 connection

M = Opening/Closing

Com = COMMON

Motor 1

Motor 2 connection

M = Opening /Closing

Com = COMMON

Motor to be connected in case

of single-leaf.

M1

M2

Cap M2

Cap M1

Example

POWER SUPPLY INPUT

NOTE: For power supply connection follow the rules in

force

MOTORS CONNECTION, CAPACITY AND POWER SUPPLY

CN4

Phase 1

Neutral

Phase 2

Phase 1

Neutral

Phase 2

CN3

CN4

Line

Neutral

67411385

CN3

CN6

24 25 26 27 28 29 30 31 32 33

L N

27

28

32

33

24

25

26

29

30

31

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

42

Rev.07 - 12/2014

Limit switch

Does not need a jumper when not connected.

For the limit switch function, limit switches must be installed, both in

opening and closing. In the case of single-leaf connect motor 1 (it is not

necessary to bridge the limit switches of motor 2).

Anti-intrusion function can be activated. This function needs at least

one limit switch, which pushes the motor in closing direction once it’s

released.

The right operation of the limit switch is guaranteed when

the motors turning direction correspond with the respective

employed limit switche.

Com = Common

C= Contact

LIMIT SWITCH, ELECTROLOCK CONNECTION

67411385

!!

Limit switch

M1 opening

Limit switch

M1 closing

Limit switch

M2 opening

Limit switch

M2 closing

ELECTROLOCK

Electrolock output

A 12V 15W max electrolock can be connected

Electrolock can be deactivated when not used for energy saving on

the control unit. Electrolock release can be timed from 0 to 5 s.

The electrobrake can be set: only before opening, only before

closing or in both directions.

EXP

DS1

DS2

RL4 RL3 RL2 RL1

L4

L3

L2

IC2

- M2+

1 CNP

CN1

L1

M1

24V~ / (ac/dc)

o

230V~

1 2 3 4 5 6 7 8

1

2

3

4

TRAFFIC LIGHT CARD CONNECTION

Connect on

EXP terminal

14 15 16 17 18 19 20 21 22 23

CN2

N.C.

N.C.

N.C.

N.C.

14

18

15

18

16

18

22 23

17

18

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

43

Rev.07 - 12/2014

ALARM DESCRIPTION

Note 1: If in the diagnostics shows "Max. cycles reached ", do the maintenance and / or reset the number of cycles

performed.

Note2: To exit from the error messages, press OK. If the error persists, make all required checks for the specific

error and / or disconnect the device that generates the error to see if the error disappears.

At each opening and closing of the automation the flashing light will blink. It blinks once per second during

opening and twice per second during closing, while it remains lit during pause.

It is possible to view the alarms also on the flashing light or on the control lamp, simply by observing the number of

flashes emitted and verifying the reference in the table below:

Signals Kind of alarm

Solutions

FA LVRE OTOR

u

FA LVRE24UAVK

FA LVRE SELF TEST

FA LVRE L T SU TCK

U

FA LVRE FLASK NG L GKT

Motors current

failure

AUX output voltage

Sure there are no short circuits on the motor or on the control

unit.

Make sure there are no short circuits on wiring or control unit

and no overload.

Power supply failure

Check the network or the F2 fuse

Self-test photocells

failure

Limit switch

activation failure

Flashing lamp failure

Check the photocells operation and / or connections on the

control unit.

Check the operation of both limit switches and / or

correspondence between movement direction of the motor

and engaged limit switches.

Check connections and / or conditions of the lamp.

Blinks

9

2

3

6

4

Blinks

5

7

6

4 fast

Cause of alarm

Motors failure

Photocell in closing

Photocell in opening

Collision in opening

Safety edge

Cause of alarm

Stop

Max. Cycles reached

Collision in closing

Limit switch fault

67411385

FA LVRE net

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

44

Potentiometer failure

FA LVRE POTENTIO ETER

U

The message appears only if the potentiometer is ON and the

potentiometer (LE) card is broken or not connected.

Rev.07 - 12/2014

67411385

Advises

Make sure all Safeties are turned ON

All N.C. contacts must have jumpers

Problem Found Possibile Cause Solutions

Motor doesn’t respond to any

START impulse

Gate doesn’t move while the

motor is running

Gate doesn’t reach the complete

Open / Closed position

The gate opens but doesn’t

close

The gate doesn’t close

automatically

a.) Check the connected N.C. contacts

b.) Burnt fuse

a.) The motor is in the released position

b.) There is an obstacle

a.) Pause time set to high

b.) Control unit in semi-autom. logic

a.) Wrong setting of the limit switches

b.) Error on programming

c.) Gate is stopped by an obstacle

d.) Torque too low

a.)

.) Ammeter alarm

e.) Encoder alarm

The contacts of the photocells are

connected and open

b.) The stop contact is connected and open

c.) The edge contact is open

d

a.) Check the connections or the jumpers on the

connections of the safety edges or of the stop

and of the photocell if connected

b.) Replace the burned fuse on the control unit

a.) Re-lock the motor

b.) Remove obstacle

a.) Adjust pause time

a.) Set limit switches

b.) Repeat programming

c.) Remove obstacle

d.) Increase torque parameter

a.) b.) c.) Check the jumpers or the

signals indicated on the warning lamp

d.) Check if the ammeter alarm has

intervened and eventually increase the

torque parameter.

b.) Set the pause parameter on a different

value from the off

TROUBLE SHOOTING

Page for both instaler and user

WAREHOUSING TEMPERATURES

T

min

T

Max

Dampness

min

Dampness

Max

5% Not condensing 90% Not condensing

MAINTENANCE

Considering the number of working cycles and the kind of gate, if the gate has changed the clutches and doesn’t work it’s necessary to

periodically proceed, with the learning times reprogramming on the electronic control unit.

Periodically clean the optical systems of the photocells.

REPLACEMENTS

Any request for spare parts must be sent to:

SEA S.p.A. - Zona Ind.le, 64020 S.ATTO - Teramo - Italia

SAFETY AND ENVIRONMENTAL COMPATIBILITY

Disposal of the packaging materials of products and/or circuits should take place in an approved disposal facility.

REGULAR PRODUCT DISPOSAL (electric and electronic waste)

(It’s applicable in EU countries and in those ones provided with a differential waste collection)

The brand that you find on the product or on documentation signals that the product must not be disposed off together with other domestic

waste at the end of life cycle. In order to avoid any possible environmental or health damage caused by irregular waste disposal, we

recommand to separate this product from other forms of waste and to recycle it in a responsible way in order to provide the sustainable re-use of

material resources. Domestic users are invited to contact the retailer where the product has been purchased or the local office in charge of all

the information related to differential watse collection and recycling of this kind of product.

STORING

Materials handling must be made with appropriate vehicles..

WARRANTY LIMITS

SEA reserves the right to make any required modification or change to the products and/or to this manual without any advanced notice

obligation.

For the guarantee see the sales conditions on the official SEA price list.

- 20°C + 65°C

e.) Check the reading of the Encoder

and/or the sensibility

English

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

45

Rev.07 - 12/2014

TERMS OF SALES

EFFICACY OF THE FOLLOWING TERMS OF SALE: the following general terms of sale shall be applied to all orders sent to SEA S.p.A.

All sales made by SEA to all costumers are made under the prescription of this terms of sales which are integral part of sale contract and

cancel and substitute all apposed clauses or specific negotiations present in order document received from the buyer.

GENERAL NOTICE The systems must be assembled exclusively with SEA components, unless specific agreements apply. Non-

compliance with the applicable safety standards (European Standards EM12453 – EM 12445) and with good installation practice

releases SEA from any responsibilities. SEA shall not be held responsible for any failure to execute a correct and safe installation under

the above mentioned standards.

1) PROPOSED ORDER The proposed order shall be accepted only prior SEA approval of it. By signing the proposed order, the Buyer

shall be bound to enter a purchase agreement, according to the specifications stated in the proposed order.

On the other hand, failure to notify the Buyer of said approval must not be construed as automatic acceptance on the part of SEA.

2) PERIOD OF THE OFFER The offer proposed by SEA or by its branch sales department shall be valid for 30 solar days, unless

otherwise notified.

3) PRICING The prices in the proposed order are quoted from the Price List which is valid on the date the order was issued. The discounts

granted by the branch sales department of SEA shall apply only prior to acceptance on the part of SEA. The prices are for merchandise

delivered ex-works from the SEA establishment in Teramo, not including VAT and special packaging. SEA reserves the right to change at

any time this price list, providing timely notice to the sales network. The special sales conditions with extra discount on quantity basis (Qx,

Qx1, Qx2, Qx3 formula) is reserved to official distributors under SEA management written agreement.

4) PAYMENTS The accepted forms of payment are each time notified or approved by SEA. The interest rate on delay in payment shall be

1.5% every month but anyway shall not be higher than the max. interest rate legally permitted.

5) DELIVERY Delivery shall take place, approximately and not peremptorily, within 30 working days from the date of receipt of the order,

unless otherwise notified. Transport of the goods sold shall be at Buyer’s cost and risk. SEA shall not bear the costs of delivery giving the

goods to the carrier, as chosen either by SEA or by the Buyer. Any loss and/or damage of the goods during transport, are at Buyer’s cost.

6) COMPLAINTS Any complaints and/or claims shall be sent to SEA within 8 solar days from receipt of the goods, proved by adequate

supporting documents as to their truthfulness.

7) SUPPLY The concerning order will be accepted by SEA without any engagement and subordinately to the possibility to get it’s supplies

of raw material which is necessary for the production; Eventual completely or partially unsuccessful executions cannot be reason for

complains or reservations for damage. SEA supply is strictly limited to the goods of its manufacturing, not including assembly, installation

and testing. SEA, therefore, disclaims any responsibility for damage deriving, also to third parties, from non-compliance of safety

standards and good practice during installation and use of the purchased products.

8) WARRANTY The standard warranty period is 12 months. This warranty time can be extended by means of expedition of the warranty

coupon as follows:

SILVER: The mechanical components of the operators belonging to this line are guaranteed for 24 months from the date of

manufacturing written on the operator.

GOLD: The mechanical components of the operators belonging to this line are guaranteed for 36 months from the date of manufacturing

written on the operator.

PLATINUM: The mechanical components of the operators belonging to this line are guaranteed for 36 months from the date of

manufacturing written on the operator. The base warranty (36 months) will be extended for further 24 months (up to a total of 60 months)

when it is acquired the certificate of warranty which will be filled in and sent to SEA S.p.A. The electronic devices and the systems of

command are guaranteed for 24 months from the date of manufacturing. In case of defective product, SEA undertakes to replace free of

charge or to repair the goods provided that they are returned to SEA repair centre. The definition of warranty status is by unquestionable

assessment of SEA. The replaced parts shall remain propriety of SEA. Binding upon the parties, the material held in warranty by the

Buyer, must be sent back to SEA repair centre with fees prepaid, and shall be dispatched by SEA with carriage forward. The warranty

shall not cover any required labour activities.

The recognized defects, whatever their nature, shall not produce any responsibility and/or damage claim on the part of the Buyer against

SEA. The guarantee is in no case recognized if changes are made to the goods, or in the case of improper use, or in the case of tampering

or improper assembly, or if the label affixed by the manufacturer has been removed including the SEA registered trademark No. 804888.

Furthermore, the warranty shall not apply if SEA products are partly or completely coupled with non-original mechanical and/or electronic

components, and in particular, without a specific relevant authorization, and if the Buyer is not making regular payments. The warranty

shall not cover damage caused by transport, expendable material, faults due to non-conformity with performance specifications of the

products shown in the price list. No indemnification is granted during repairing and/or replacing of the goods in warranty. SEA disclaims

any responsibility for damage to objects and persons deriving from non-compliance with safety standards, installation instructions or use

of sold goods. The repair of products under warranty and out of warranty is subject to compliance with the procedures notified by SEA.

9) RESERVED DOMAIN A clause of reserved domain applies to the sold goods; SEA shall decide autonomously whether to make use of

it or not, whereby the Buyer purchases propriety of the goods only after full payment of the latter.

10) COMPETENT COURT OF LAW In case of disputes arising from the application of the agreement, the competent court of law is the

tribunal of Teramo. SEA reserves the faculty to make technical changes to improve its own products, which are not in this price list at any

moment and without notice. SEA declines any responsibility due to possible mistakes contained inside the present price list caused by

printing and/or copying. The present price list cancels and substitutes the previous ones. The Buyer, according to the law No. 196/2003

(privacy code) consents to put his personal data, deriving from the present contract, in SEA archives and electronic files, and he also

gives his consent to their treatment for commercial and administrative purposes.

Industrial ownership rights: once the Buyer has recognized that SEA has the exclusive legal ownership of the registered SEA brand

num.804888 affixed on product labels and / or on manuals and / or on any other documentation, he will commit himself to use it in a way

which does not reduce the value of these rights, he won’t also remove, replace or modify brands or any other particularity from the

products. Any kind of replication or use of SEA brand is forbidden as well as of any particularity on the products, unless preventive and

expressed authorization by SEA.

In accomplishment with art. 1341 of the Italian Civil Law it will be approved expressively clauses under numbers:

4) PAYMENTS - 8) GUARANTEE - 10) COMPETENT COURT OF LOW

GATE 2 DG R1

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

67411385

91

Rev.07 - 12/2014

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

67411385

Italiano

English

Français

AVVERTENZE GENERALI PER INSTALLATORE E UTENTE

1. Leggere attentamente le Istruzioni di Montaggio e le Avvertenze Generali prima di iniziare l’installazione del prodotto. Conservare la documentazione per

consultazioni future

2. Non disperdere nell’ ambiente i materiali di imballaggio del prodotto e/o circuiti

3. Questo prodotto è stato progettato e costruito esclusivamente per l’utilizzo indicato in questa documentazione. Qualsiasi altro utilizzo non espressamente indicato

potrebbe pregiudicare l’integrità del prodotto e/o rappresentare fonte di pericolo. L’uso improprio è anche causa di cessazione della garanzia. La SEA S.p.A. declina

qualsiasi responsabilità derivata dall’uso improprio o diverso da quello per cui l’automatismo è destinato.

4. I prodotti SEA sono conformi alle Direttive: Macchine (2006/42/CE e successive modifiche), Bassa Tensione (2006/95/CE e successive modifiche), Compatibilità

Elettromagnetica (2004/108/CE e successive modifiche). L’installazione deve essere effettuata nell’osservanza delle norme EN 12453 e EN 12445.

5. Non installare l’apparecchio in atmosfera esplosiva.

6. SEA S.p.A. non è responsabile dell’inosservanza della Buona Tecnica nella costruzione delle chiusure da motorizzare, nonché delle deformazioni che dovessero

verificarsi durante l’ uso.

7. Prima di effettuare qualsiasi intervento sull’impianto, togliere l’alimentazione elettrica e scollegare le batterie. Verificare che l’impianto di terra sia realizzato a

regola d’arte e collegarvi le parti metalliche della chiusura.

8. Per ogni impianto SEA S.p.A. consiglia l’utilizzo di almeno una segnalazione luminosa nonché di un cartello di segnalazione fissato adeguatamente sulla struttura

dell’infisso.

9. SEA S.p.A. declina ogni responsabilità ai fini della sicurezza e del buon funzionamento della automazione, in caso vengano utilizzati componenti di altri produttori.

10. Per la manutenzione utilizzare esclusivamente parti originali SEA.

11. Non eseguire alcuna modifica sui componenti dell’automazione.

12. L’installatore deve fornire tutte le informazioni relative al funzionamento manuale del sistema in caso di emergenza e consegnare all’Utente utilizzatore

dell’impianto il libretto d’avvertenze allegato al prodotto.

13. Non permettere ai bambini o persone di sostare nelle vicinanze del prodotto durante il funzionamento. L’applicazione non può essere utilizzata da bambini, da

persone con ridotte capacità fisiche, mentali, sensoriali o da persone prive di esperienza o del necessario addestramento. Tenere inoltre fuori dalla portata dei

bambini radiocomandi o qualsiasi altro datore di impulso, per evitare che l’automazione possa essere azionata involontariamente.

14. Il transito tra le ante deve avvenire solo a cancello completamente aperto.

15. Tutti gli interventi di manutenzione, riparazione o verifiche periodiche devono essere eseguiti da personale professionalmente qualificato. L’utente deve

astenersi da qualsiasi tentativo di riparazione o d’intervento e deve rivolgersi esclusivamente a personale qualificato SEA. L’utente può eseguire solo la manovra

manuale.

2

16. La lunghezza massima dei cavi di alimentazione fra centrale e motori non deve essere superiore a 10 m. Utilizzare cavi con sezione 2.5 mm . Utilizzare cablaggi

con cavi in doppio isolamento (cavi con guaina) nelle immediate vicinanze dei morsetti specie per il cavo di alimentazione (230V). Inoltre è necessario mantenere

adeguatamente lontani (almeno 2.5 mm in aria) i conduttori in bassa tensione (230V) dai conduttori in bassissima tensione di sicurezza (SELV) oppure utilizzare

un’adeguata guaina che fornisca un isolamento supplementare avente uno spessore di almeno 1 mm.

GENERAL NOTICE FOR THE INSTALLER AND THE USER

1. Read carefully these Instructions before beginning to install the product. Store these instructions for future reference

2. Don’t waste product packaging materials and /or circuits.

3. This product was designed and built strictly for the use indicated in this documentation. Any other use, not expressly indicated here, could compromise the good

condition/operation of the product and/or be a source of danger. SEA S.p.A. declines all liability caused by improper use or different use in respect to the intended

one.