mundoclima Series Aerotherm MAM-V9″Monobloc Aerotherm Heat Pump” Guía de instalación

- Categoría

- Bombas de calor

- Tipo

- Guía de instalación

Este manual también es adecuado para

MONOBLOC AEROTHERM MAM-V9

Owner's & Installation manual

www.mundoclima.com

R32

SO30180 ~ SO30188

FR: "Manual d’utilisation et d’installation" voir www.mundoclima.com/fr

DE: "Benutzer- und Installationshandbuch" sehen www.mundoclima.com/de

PT: "Manual de instalaçao e do utilizador" ver www.mundoclima.com/pt

Manual de usuario e instalación

EN page 89

8

9

ÍNDICE

MEDIDAS DE SEGURIDAD

INFORMACIÓN GENERAL

ACCESORIOS

3.1

3.2

Accesorios provistos con la unidad

Accesorios provistos por el proveedor

ANTES DE LA INSTALACIÓN

INFORMACIÓN IMPORTANTE DEL REFRIGERANTE

LUGAR DE INSTALACIÓN

6.1

6.2

Selección de una ubicación en climas fríos

Selección de una ubicación en climas cálidos

PRECAUCIONES DE INSTALACIÓN

7.1

Dimensiones

7.2

7.3

7.4

Requisitos de instalación

Requisitos del espacio de mantenimiento

APLICACIONES TÍPICAS

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

Aplicación 1

Aplicación 2

Aplicación 3

Aplicación 4

Aplicación 5

Aplicación 6

Aplicación 7

Aplicación 8

VISTA DE LA UNIDAD

10

Componentes principales

Tubería de agua

Añadir agua

Aislamiento de la tubería de agua

9.7

Cableado

ARRANQUE Y CONFIGURACIÓN

Curvas climáticas

02

04

06

06

06

07

09

09

10

10

11

11

12

13

15

16

17

20

22

23

24

25

27

34

38

39

39

49

51

1

2

3

4

5

6

7

9.1

9.2

9.3

9.4

9.5

9.6

10.1

10.2

Manual de Instalación y Usuario

ES

11

10.3

10.4

10.5

10.6

10.7

PRUEBA DE FUNCIONAMIENTO Y COMPROBACIONES FINALES

12

13

11.1

11.2

MANTENIMIENTO Y CUIDADO

LOCALIZACIÓN DE AVERÍAS

14

13.1

13.2

13.3

13.4

Guías generales

Síntomas generales

ESPECIFICACIONES TÉCNICAS

14.1

14.2

General

15 SUSTITUCIÓN DE LAS VÁLVULAS DE SEGURIDAD

52

52

53

53

54

66

67

67

67

68

70

71

77

77

78

78

Comprobaciones previas

Encendido de la unidad

Prueba de funcionamiento (manual)

Parámetros de funcionamiento

Códigos de error

16 INFORMACIÓN DE MANTENIMIENTO

12/14/16 kW

5/7/9 kW

Sistema de refrigerante

Sistema de control eléctrico

Bloque de terminales

Sistema

hidráulico

después de la instalación.

Racor de instalación

NOT

A

Capacidad

de

Resistencia

5

7

3kW

9

Monofásico

12

14

3kW o 4.5kW

16 12

12/14/16 kW

Trifásico

14

4,5kW

5/7/9 kW

12/14/16 kW

16

-

Modelo

1

Este símbolo muestra que el manual de instalación y usuario se debe leer cuidadosa-

mente.

Este símbolo muestra que el personal de mantenimiento debe manipular este equipo

teniendo en cuenta el manual de instalación.

Este símbolo muestra que el personal de mantenimiento debe manipular este equipo

teniendo en cuenta el manual de instalación.

Este símbolo muestra que la información está disponible en el manual de instalación y

usuario.

1 MEDIDAS DE SEGURIDAD

Las precauciones enumeradas aquí se dividen en los siguientes tipos, que son muy importantes, así que asegúrese de

seguirlas cuidadosamente.

i

INFORMACIÓN

Lea estas instrucciones cuidadosamente antes de la instalación. Mantenga este manual a la mano para referencias

futuras.

Una mala instalación de la unidad o sus accesorios puede provocar descargas eléctricas, cortocircuitos, fuga, incen-

equipo de protección personal adecuado, como guantes y gafas de seguridad, cuando instale la unidad o cuando

realice actividades de mantenimiento.

Póngase en contacto con su distribuidor para obtener más ayuda.

Precaución: Riesgo de incendios/

ADVERTENCIA

-

¡PELIGRO!

ADVERTENCIA

PRECAUCIÓN

T

ambién se puede usar para alertar contra prácticas poco seguras.

NOT

A

Descripción de símbolos mostrados en la unidad interior o exterior:

2

¡PELIGRO!

Antes de tocar los componentes eléctricos, apague el equipo.

descargas eléctricas.

Antes de tocar los componentes eléctricos, desconecte el equipo.

ADVERTENCIA

•

•

que puedan causar lesiones.

•

incendios.

•

•

del equipo y posibles lesiones.

•

Una mala instalación puede provocar accidente debido a la caída del equipo.

•

-

to de alimentación o una mala instalación eléctrica pueden provocar descargas eléctricas o incendios.

•

Asegúrese de instalar un interruptor diferencial según la normativa vigente. Una mala instalación del interruptor

diferencial puede ocasionar descargas eléctricas e incendios.

•

-

lación incompleta o incorrecta puede provocar incendios.

•

Si el panel frontal no está bien instalado en su lugar se puede causar el sobrecalentamiento de los terminales des-

cargas eléctricas o incendios.

•

•

de refrigerante durante el funcionamiento ni inmediatamente después porque pueden estar calientes o frías, en

-

rese de usar guantes de protección apropiados.

•

-

internas y asegúrese de usar guantes apropiados.

PRECAUCIÓN

-

Tubería de gas:

-

para evitar el ruido).

regulaciones nacionales vigentes sobre el cableado. Si la entrada de alimentación está dañada, debe ser sustituida

3

pueden caer o provocar fugas de agua.

-

dadas puede causar fugas refrigerante.

- Cuando el equipo emite ondas electromagnéticas. Las ondas electromagnéticas pueden alterar el sistema de

control y causar un mal funcionamiento del equipo.

causar un incendio.

- Donde el aire contenga altos niveles de sal, cercano al mar

.

- Dentro de vehículos o depósitos.

- Donde haya vapores de sustancias ácidas o alcalinas.

-

los peligros que conlleva.

supervisión.

Si el cable de alimentación está dañado, se debe sustituir por el fabricante o su distribuidor o un especialista del

servicio técnico para evitar riesgos.

-

establecidos. Póngase en contacto con las autoridades locales para que le informen sobre los centros de recolec-

de sustancias nocivas pueden salir y llegar a las aguas subterráneas del subsuelo. Esto puede contaminar la cade-

na alimenticia y tener consecuencias nocivas para su salud y la de todos.

-

-

tricidad y gas.

Antes de la instalación, compruebe si la fuente de alimentación del usuario cumple con los requisitos de la instala-

etc.). Si no se cumplen los requisitos de instalación eléctrica del producto, se prohíbe la instalación del producto

hasta que se instale correctamente

de alimentación trifásica y se evitará que varias unidades se monten en la misma fase de la fuente de alimentación

trifásica.

NOTA

-

-

Si hay un sistema de detección de fugas instalado, se debe comprobar al menos cada 12 meses. Es muy reco-

incidencias.

2 INTRODUCCIÓN GENERAL

Estas unidades se usan tanto para las aplicaciones de calefacción como para refrigeración. Las unidades se pueden com-

suministrado) y kit solar (no suministrado).

para las diferentes unidades se relaciona a continuación.

4

Modelo

5~9kW 12~16kW

V

olumen depósito/ L

Mín. 100 200

Recomendado

200 300

-

biador de

calor (Ser-

pentín de

-

dable)

Calef.

área de

intercam-

bio/m

2

Mín. 1.4 1.75

Recomendado

2.5 4

V

olumen

/L

Mín. 12 14

Recomendado

20 32

-

biador

de calor

(Serpentín

esmaltado)

Calef.

área de

intercam-

bio/m

2

Mín. 1.7 2.5

Recomendado

3 5.6

V

olumen

/L

Mín. 14 20

Recomendado

24 45

Capacidad / Carga

ճ

ղ

ձ

ձCapacidad de la bomba de calor.

ղCapacidad de calefacción requerida (depende el lugar).

ճCapacidad de calor adicional ofrecida por la resistencia

Depósito de ACS (no suministrado)

Un depósito de ACS (con una resistencia eléctrica de

apoyo de 3 kW) se puede conectar a la unidad.

Los requisitos del depósito dependen del tipo de unidad

así como del material del intercambiador de calor.

Sensor de tem-

peratura (T5)

Serpentín

Salida

Resistencia del

depósito (TBH)

Entrada

Si el volumen del depósito es superior a 240L, el sensor de

temperatura (T5) debe instalarse en una posición superior

a la mitad de la altura del depósito.

Si el volumen del depósito es inferior a 240L, el sensor de

temperatura debe instalarse en una posición superior a 2/3

de la altura del depósito.

sensor de temperatura.

El intercambiador de calor (serpentín) debe instalarse por

-

sito debe ser inferior a 5 m.

43

30

-10

-25

5 12 25 35 50 60

46

*43

20

10

-5

5 10

25 50

35

30

-10

-25

5 12 25 35

55 60

Termostato ambiente (no suministrado)

El termostato de ambiente se puede conectar a la

unidad (el termostato de ambiente se debe mantener

lugar de instalación).

Kit solar para depósito de ACS (no suministrado)

Se puede conectar a la unidad un kit solar.

Kit de alarma a distancia (no suministrado)

Se puede conectar a la unidad un kit de alarma a

distancia.

intervalo de subida

5

-25~-16 -15~-11 -10~-6 -5~-1

“DHW Temp.

caudal agua

5~9kW 45 48 50 52

12~16kW 40 45 48 50

0~4 5~14 15~19 20~24

“DHW Temp.

caudal agua

5~9kW 55 55 55 52

12~16kW 53 55 55 50

25~29 30~34 35~39 40~43

“DHW Temp.

caudal agua

5~9kW 50 50 48 45

12~16kW 50 48 48 45

11 12 13

10 9 9 8

14 15 16 17

8776

18 19 20

6655

3 ACCESORIOS

3.1 Accesorios provistos con la unidad

Accesorios de instalación

Manual de usuario e

instalación

Ficha de producto

Filtro en forma de

Y

Panel de control

Bridas

Sensor de temperatura para el

depósito de agua caliente sanita-

ria o fuente de calor adicional*

Cable de prolongación

para T5

Cantidad

5~9kW

1

1

1

1

2

1

0

3

1

1

12~16kW

1

1

1

1

1

1

2

3

1

1

la temperatura del agua. Si está instalado solamente el

depósito de agua caliente sanitaria, el sensor de tempera-

tura puede funcionar como T5. Si está instalada solamente

la caldera, el sensor de temperatura puede funcionar como

T1B. Si ambas unidades están instaladas, se necesita un

sensor de temperatura adicional (póngase en contacto con

el proveedor). El sensor de temperatura debe conectarse

al puerto correspondiente en la placa de control principal

del sistema hidráulico (consulte la sección 9.3.1 Placa de

control principal del módulo hidráulico).

3.2

Accesorios opcionales

Sensor de temperatura de la tempe-

ratura de agua (T1B)

Cable de prolongación (para

T1B)

Preparación previa a la instalación

Manipulación

Debido a las grandes dimensiones y el peso elevado, la unidad solo se puede manipular mediante eslingas de elevación

colocados en el bastidor de base.

-

ción de hielo mediante la bomba de calor y la resistencia

Debido a que puede

ocurrir una falla de energía cuando la unidad está desaten-

en el sistema de agua. (Consulte con 9.4 Tubería de agua).

En el modo de refrigeración, a continuación se indica la tem-

peratura mínima de salida del agua (T1stoph) que la unidad

En el modo de calefacción, a continuación se indica la

-25 -24 -23 -22

35 35 35 37

-21 -20 -19 -18

39 40 42 44

-17 -16 -15 -14

46 48 50 52

-13 -12 -11 -10~30

54 56 58 60

31 32 33 34

59 58 57 56

35 36 37 38

55 55 55 55

39 40 41 42

54 53 52 51

43 44 45 46

50 50 50 50

4

ANTES DE LA INSTALACIÓN

Manual de usuario e

instalación del panel

de control

6

Para evitar lesiones, no toque la entrada de aire ni las lamas de aluminio de la unidad.

¡La unidad es muy pesada! Evite que se caiga la unidad al inclinarse durante la manipulación.

1000mm

540

PRECAUCIÓN

El gancho y el baricentro de

la unidad deben estar en una

línea en dirección vertical

para evitar una inclinación

inadecuada.

Pase la cuerda por los

soporte de madera

234 707

5/7/9 kW (unidad:mm)

540

605

222.5

641

12/14/16 kW (unidad:mm)

5 INFORMACIÓN IMPORT

ANTE DEL REFRIGERANTE

T

ipo de refrigerante R32; Volumen de GWP: 675.

GWP = Potencial de Calentamiento Global

Modelo

5kW

7kW

9kW

12kW

14kW

16kW

Volumen de refrigerante cargado de fábrica en la unidad

Refrigerante/kg

2.00

2.00

2.00

2.80

2.80

2.80

2 equivalentes

1.35

1.35

1.35

1.89

1.89

1.89

605

7

PRECAUCIÓN

Frecuencia de comprobaciones de fugas de refrigerante

2

o más, uni-

2

, comprobar al menos cada 12 meses, o

cuando se instale un sistema de detección

de fugas al menos cada 24 meses.

2

2

, comprobar al menos cada 12 meses, o cuando se instale un

sistema de detección de fugas al menos cada 12 meses.

2

o más, comprobar al menos cada 3 meses, o cuando se instale un s

istema de detección de fugas al menos

cada 6 meses.

invernadero.

6 LUGAR DE INSTALACIÓN

ADVERTENCIA

el interior

, se debe añadir un dispositivo adicional de detección de refrigerante y un equipo de ventilación de acuerdo

-

tos y pequeños animales.

Los animales pequeños cuando entran en contacto con los componentes eléctricos pueden provocar averías, humo

o incendios. Por favor, informe al cliente de mantener limpia el área alrededor de la unidad.

Seleccione un lugar de instalación donde se cumplan las condiciones siguientes y con el acuerdo del cliente: - Lugares bien

ventilados.

- Donde la unidad no moleste a los vecinos.

-

do).

- Donde se pueda evitar lluvia todo lo posible.

-

nos) donde se crea mucho polvo, se debe cubrir la unidad.

- Asegúrese de que se toman las precauciones necesarias en caso de fuga de refrigerante de acuerdo con las leyes y nor-

mativas locales pertinentes.

Viento fuerte de 5 m/s o más contra la salida de aire de la unidad causa cortocircuito (absorción de la descarga de aire) y

esto tiene las consecuencias siguientes:

- Deterioro de la capacidad de funcionamiento.

- Aceleración de la escarcha durante la calefacción.

- Problemas con el funcionamiento debido al aumento de la alta presión.

8

Modelo

5~9kW

12~16kW

A

(mm)

A

En caso de fuertes vientos y cuando se puede prever la

instalación de la unidad (cualquiera de ellas está bien):

pantalla.

Modelo

5~9kW

12~16kW

B

B(mm)

instalación.

la dirección del viento.

la base, para que salga el agua usada en torno a la

unidad.

la unidad sobre una base de bloques de hormigón, etc.

(la altura de la base debe ser de unos 100 mm (3,93").

Si instala la unidad sobre un bastidor, instale una placa

Al instalar la unidad reste especial atención si es un lu-

Si instala la unidad sobre una base debe

evitar que se acumule el agua del drena

-

NOT

A

¡La unidad es muy pesada!

-

tes de transporte.

6.1 Selección de una ubicación en

climas fríos

Consulte "Manipulación" en la sección “4.

Antes de la

instalación.

NOT

A

Cuando funciona la unidad en climas fríos, asegú-

rese de seguir las instrucciones que se describen a

continuación.

su lado de aspiración frente a la pared.

el lado de descarga de aire de la unidad.

Durante las tormentas de nieve es muy importante

seleccionar un sitio de instalación donde la nieve no

afecte la unidad. Si es posible que haya una caída

lateral de la nieve, asegúrese de que el serpentín del

intercambiador de calor no se afecte por la nieve (si es

necesario instale un techo).

ձ

ղ

ձ

ղ Monte una base.

tierra para evitar que se cubra de nieve.

6.2 Selección de una ubicación en

climas cálidos

del sol.

9

Modelo A B C D E F G H J

5/7/9kW 1210 374 402 502 404 215 277 945 165 59

12/14/16kW 1404 373 405 760 361 280 / 1414 176 144

7 PRECAUCIONES DE INST

ALACIÓN

7.1 Dimensiones

5/7/9 kW (unidad: mm) 12/14/16 kW (unidad: mm)

7.2 Requisitos de instalación

Compruebe la resistencia y la nivelación del suelo de instalación de manera que la unidad no provoque ninguna vibración o

ruido durante el funcionamiento.

10 Espárragos

Goma

Alfombrilla de

goma a prueba

de golpes

Solido

o techo

Base de

hormigón

(Unidad: mm)

H

J

I

H

J

I

E D

B

F

G

C

A

E D

B

F

C

A

10

por un tapón de

no puede cumplir

con los requisitos de

mismo tiempo.

-

5/7/9 kW

NOT

A

Es necesario instalar un aislamiento térmico si el agua no puede drenar en climas fríos, incluso si se ha abierto un

12/14/16

kW

7.4 Requisitos del espacio de mantenimiento

7.4.1 En caso de poco espacio de instalación

1) En caso de obstáculos frente del lado de salida. 2) En caso de que haya obstáculos frente a la entrada de aire.

A

Modelo

5~9kW

12~16kW

A(mm)

7.4.2 En caso de instalación de varias hileras de equipo (en el techo, etc.).

1) En caso de instalar una unidad por hilera.

11

Modelo A

(mm) B1(mm) B2(mm) C (mm)

5~9kW

12~16kW

Modelo

A

(mm) B1(mm) B2(mm) C (mm)

5~9kW

12~16kW

H

B1

C

A

H

B1

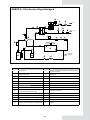

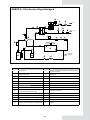

8 APLICACIONES

TÍPICAS

8.1 Aplicación

1

Espacio para calefacción con un termostato ambiente conectado a la unidad.

<1/2 H

B2

C

A

<1/2 H

B2

12

Código

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2

3

1

1.6

1.7

1.5

1.8

1.3

1,4 1,2

1.1

2 3

Manómetro

Válvula de seguridad

Placa intercambiadora de calor

()

Purgador

P_i: Bomba recirculadora de la unidad

Filtro en forma de Y

Válvula de cierre (no suministrada)

6 7

8.1

8.2

Código

4

5

6

7

8

8.1

8.2

9

10

11

FHL 1…n

T

9

NOTA

4

5

10

11

----

FHL1

FHL2 FHLn

Panel de control

T

ermostato ambiente (no suministrado)

Válvula de llenado (no suministrada)

Depósito de equilibrio (no suministrado)

Purgador

Colector (no suministrado)

Suelo radiante (no suministrado)

----

El volumen del tanque de equilibrio (8) debe ser mayor que 40L (para una unidad de 5~9kW, mayor que 20L). La vál-

-

Funcionamiento de la unidad y calefacción:

Cuando un termostato ambiente se conecta a la unidad y cuando hay una solicitud de calefacción desde ese termostato, la uni-

se detendrán. Aquí se usa el termostato ambiente como interruptor.

NOT

A

Asegúrese de conectar los cables del termostato a los terminales correctos, debe seleccionarse el método B (véase

-

8.2 Aplicación

2

ACS que está conectado a la unidad.

8

13

Código

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2

3

4 6

7

8

8.1

1

1.6

1.7

1.5

1.8

1.3

1,4 1,2

1.1

2 3

Manómetro

Válvula de seguridad

Placa intercambiadora de calor

()

Purgador

P_i: Bomba recirculadora de la unidad

Filtro en forma de Y

Válvula de cierre (no suministrada)

Panel de control

Válvula de llenado (no suministrada)

Depósito de equilibrio (no suministrado)

18

6 7

Purgador

8.1

8.2

8

9

Código

8.2

9

10

11

12

12.1

12.2

12.3

13

14

15

16

17

18

FHL 1…n

4

10

12.1

12

13

12.3

12.2

11

----

14

15

16

FHL1

FHL2 FHLn

Colector (no suministrado)

Depósito de ACS (no suministrado)

Purgador

Resistencia del depósito

T5: Sensor de temperatura del depósito de ACS

Grifo de agua caliente (no suministrado)

P_d: Bomba ACS (no suministrada)

Válvula de 1 vía (no suministrada)

Válvula de bypass (no suministrada)

SV1: Válvula de 3 vías (no suministrada)

Suelo radiante (no suministrado)

----

/ /

NOT

A

El volumen del tanque de equilibrio (8) debe ser mayor que 40L (para una unidad de 5~9kW, mayor que 20L). La válvula de

Funcionamiento de la bomba recirculadora

La bomba recirculadora (1.8) y (10) funcionarán mientras la unidad esté encendida para la calefacción.

La bomba recirculadora (1.8) bomba funcionará mientras la unidad este encendida para el

ACS (DHW).

Calefacción

1) La unidad (1) funcionará para lograr la temperatura de agua deseada según lo establecido en el panel de control.

2) Se debe seleccionar la válvula de manera que todo el tiempo se garantice el caudal de agua mínimo que se menciona

en 9.4

Tuberías de agua.

Agua caliente sanitaria (ACS)

Cuando el modo

ACS está activado (ya sea manual por el usuario o automáticamente mediante una programación) la

-

tencia eléctrica del depósito de ACS (cuando la resistencia del depósito de ACS esté en YES).

se activará para calentar el agua caliente sanitaria mediante la bomba de calor. Si hay una gran demanda de agua calien-

17

14

PRECAUCIÓN

-

ponentes/Válvula de 3 vías SV1.

NOT

A

mediante la resistencia del depósito de

ACS. Esto asegura que toda la capacidad de la bomba de calor está disponible

para la calefacción.

8.3 Aplicación 3

conecta a la unidad. La calefacción se suministra a través del circuito de suelo radiante y las unidades de fancoil. La refrige-

ración se provee solo mediante las unidades fancoil. El agua caliente sanitaria se produce mediante un depósito de

ACS que

está conectado a la unidad.

Código

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2

3

4

5

6

7

8

8.1

1

1.6

1.7

1.5

1.8

1.3

1,4 1,2

1.1

2 3

Descripción

Manómetro

Válvula de seguridad

Placa intercambiadora de calor

()

Purgador

P_i: Bomba recirculadora de la unidad

Filtro en forma de Y

Válvula de cierre (no suministrada)

Panel de control

Termostato ambiente (no suministrado)

Válvula de llenado (no suministrada)

Depósito de equilibrio (no suministrado)

Purgador

18

12.1

12

13

T

12.3

12.2

8.1

4

5

9

10

14

15

16

19

11

----

FCU1 FCU2 FCUn ----

11

6 7 ----

8.2

8

Código

8.2

9

10

11

12

12.1

12.2

12.3

13

14

15

16

18

19

FHL 1…n

FCU 1...n

/

FHL1

FHL2

FHLn

Descripción

(no suministrada)

Colector (no suministrado)

Depósito de ACS (no suministrado)

Purgador

Resistencia del depósito

T5: Sensor de temperatura del depósito de ACS

Grifo de agua caliente (no suministrado)

P_d: Bomba ACS (no suministrada)

Válvula de 1 vía (no suministrada)

SV1: Válvula de 3 vías (no suministrada)

SV2: Válvula de 2 vías (no suministrada)

Suelo radiante (no suministrado)

----

Fancoil (no suministrado)

/

15

NOT

A

El volumen del tanque de equilibrio (8) debe ser mayor que 40L (para una unidad de 5~9kW, mayor que 20L). La válvu-

Funcionamiento en calefacción y refrigeración

calefacción y refrigeración. La unidad (1) funcionará hasta lograr la temperatura deseada, ya sea fría o caliente. En modo de

suelo radiante (FHL).

PRECAUCIÓN

esquema eléctrico.

Agua caliente sanitaria (ACS)

El agua caliente sanitaria es cómo se describe en 8.2

Aplicación 2.

8.4 Aplicación

4

controlar el encendido y apagado de la unidad. La calefacción se suministra a través del circuito de suelo radiante y las unida-

des de fancoil. La refrigeración se provee solo mediante las unidades Fancoil.

1

1.6

1.7

4

11

9

1.5 ----

1.8

1.3

1,4 1,2

1.1

2 3

8,1 19

10

FCU1

FCU2

FCUn ----

11

6 7 ----

8.2

8

FHL1 FHL2

FHLn ----

17

16

Código

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2

3

4

Descripción

Manómetro

Válvula de seguridad

Placa intercambiadora de calor

()

Purgador

P_i: Bomba recirculadora de la unidad

Filtro en forma de Y

Válvula de cierre (no suministrada)

Pamel de control

Código

6

7

8

8.1

8.2

9

10

11

17

19

FHL 1…n

FCU 1...n

NOT

A

Descripción

Válvula de llenado (no suministrada)

Depósito de equilibrio (no suministrado)

Purgador

Colector (no suministrado)

Válvula de bypass (no suministrada)

SV2: Válvula de 2 vías (no suministrada)

Suelo radiante (no suministrado)

Fancoil (no suministrado)

El volumen del tanque de equilibrio (8) debe ser mayor que 40L (para una unidad de 5~9kW, mayor que 20L). La vál-

Funcionamiento de la bomba

La bomba recirculadora (1.8) y (10) funcionarán mientras la unidad esté encendida para la calefacción.

NOT

A

Como el sensor de temperatura se usa para detectar la temperatura ambiente, el panel de control (4) se debe colocar

las curvas climáticas, la unidad se apagará cuando la temp. ambiente llegue al valor deseado.

Calefacción y refrigeración

Según la temporada el cliente seleccionará calefacción o refrigeración a través del panel de control. La unidad (1) funciona-

rá en el modo calefacción o refrigeración para lograr la temperatura ambiente deseada. En el modo calefacción, la válvula

de 2 vías (19) (230 V

ac) se abrirá. El agua caliente se suministra tanto a las unidades Fancoil como a los circuitos de suelo

del circuito del suelo radiante (FHL).

PRECAUCIÓN

-

8.5 Aplicación

5

-

El funcionamiento combinado es posible para la calefacción y el ACS.

-

ción para la aplicación A.

en el cableado de campo según la ilustración para la aplicación b. En esta condición, la unidad puede enviar una señal de

encendido/apagado a la caldera en modo calefacción, pero el propio control de la caldera en modo ACS.

indica en la ilustración para la aplicación C.

17

PRECAUCIÓN

8.5.1 Aplicación

a

La caldera proporciona calor solo para la calefacción de espacios

1

1.6

1.7

1.5

1.8

1.3

1,4 1,2

8.5.2 Aplicación

b

para el calentamiento del

ACS.

1.1

2 3

12.1

18

12

13

12.3

12.2

6 7

14

15

16

8.1

8.2

8

4

9

10

16

22

23

23.1

11

----

FHL1 FHL2

FHLn

----

1

1.6

1.7

1.5

1.8

1.3

1,4 1,2

1.1

2 3

18

12.1

12

13

12.3

12.2

6 7

16

8.1

8.2

8

4

9

10

16

22

23

23.1

14

15

16

11

----

FHL1 FHL2

FHLn

----

18

8.5.3 Aplicación

C

caldera controlado por la unidad.

Código

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2

3

4

6

7

8

8.1

8.2

1

1.6

1.7

1.5

1.8

1.3

1,4 1,2

1.1

2 3

Descripción

Manómetro

Válvula de seguridad

Placa intercambiadora de calor

()

Purgador

P_i: Bomba recirculadora de la unidad

Filtro en forma de Y

Válvula de cierre (no suministrada)

Panel de control

Válvula de llenado (no suministrada)

Depósito de equilibrio (no suministrado)

Purgador

18

6 7

22

12.1

8.1

8.2

8

Código

9

10

11

12

12.1

12.2

12.3

13

14

15

16

18

22

23

23.1

FHL 1…n

AHS

NOTA

9

4

12

13

10

12.3

12.2

14

15

16

11

----

FHL1 FHL2

FHLn

Descripción

Colector (no suministrado)

Depósito de ACS (no suministrado)

Purgador

Resistencia del depósito

T5: Sensor de temperatura

Grifo de agua caliente (no suministrado)

P_d: Bomba ACS (no suministrada)

Válvula de 1 vía (no suministrada)

SV1: Válvula de 3 vías (no suministrada)

T1B: Sensor de temperatura (no suministrado)

Suelo radiante (no suministrado)

Fuente de calor adicional (caldera) (alimentación de

campo)

----

El volumen del tanque de equilibrio (8) debe ser mayor que 40L (para una unidad de 5~9kW, mayor que 20L). La vál-

independiente e instalarla en la puerta. El sensor de temperatura T1B debe instalarse a la salida del AHS y conectarse

al puerto correspondiente de la placa de control principal del módulo hidráulico (véase 9.3.1 placa de control principal

Funcionamiento

19

Los cambios frecuentes pueden provocar corrosión a la caldera y acortar su vida útil. Póngase en contacto con el proveedor

de la caldera.

-

da como aparece en el panel de control.

NOTA

calor.

PRECAUCIÓN

-

Asegúrese de que las válvulas antiretorno (no suministradas) están bien instaladas en el sistema.

El fabricante/distribuidor no se hace responsable de los daños resultantes por el no cumplimiento de estas indicacio-

nes.

8.6 Aplicación

6

Calefacción con dos termostatos ambiente a través de los circuitos de suelo radiante y las unidades fancoil. Los circuitos de

El circuito de suelo radiante requiere una temperatura del agua inferior en modo calefacción comparada a las unidades fan-

del circuito de suelo radiante. Las unidades fancoil están directamente conectadas al circuito de agua de la unidad y al del

-

diendo de la temp. requerida del agua (se necesitan circuitos de suelo radiante y/o Fancoils) se puede activar el primer pun-

NOT

A

El cableado del termostato de ambiente 5A

(para Fancoils) y 5B (para suelo radiante) debe seguir el "método C" des-

20

Código

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2

3

4

6

1

1.6

1.7

1.5

1.8

1.3

1,4 1,2

1.1

2 3

Manómetro

Válvula de seguridad

Placa intercambiadora de calor

()

Purgador

P_i: Bomba recirculadora de la unidad

Filtro en forma de Y

Válvula de cierre (no suministrada)

Panel de control

T

T

9

4

5

A

5B

8,1 10

19

M

23.1

6 7 23

8.2

8

Código

7

8

8.1

8.2

9

10

11

17

19

23

23.1

FHL 1…n

FCU 1...n

NOT

A

A

FCU1

B

FCU2

11

FCUn

FHL1

FHL2 FHLn

11

Válvula de llenado (no suministrada)

Depósito de equilibrio (no suministrado)

Purgador

Colector (no suministrado)

Válvula de bypass (no suministrada)

SV2:válvula de 2 vías (no suministrada)

Suelo radiante (no suministrado)

Fancoil (no suministrado)

17

El volumen del tanque de equilibrio (8) debe ser mayor que 40L (para una unidad de 5~9kW, mayor que 20L). La

-

-

-

Funcionamiento de las bombas

La bomba (1.8) y (10) funcionarán cuando haya una solicitud de calefacción de

A y / o B. La bomba (23.1) funcionará solo

-

da del agua. La temperatura de salida de agua depende de valor programado en el termostato ambiente que la solicitó.

de funcionar.

21

NOT

A

caliente en el circuito de calefacción, etc.).

de usar dos puntos de consigna.

8.7 Aplicación

7

Aplicación de la función de doble punto de consigna sin termostato de ambiente conectado a la unidad.

La calefacción se suministra a través del circuito de suelo radiante y las unidades de fancoil. Los circuitos de suelo radiante

El circuito de suelo radiante requiere una temperatura del agua inferior en modo calefacción comparada a las unidades

-

sitos del circuito de suelo radiante. Las unidades fancoil están directamente conectadas al circuito de agua de la unidad y al

-

pendiendo de la temperatura del agua requerida (se necesitan circuitos de suelo radiante y/o Fancoils) se puede activar el

1

1.6

1.7

1.5

1.8

1.3

1,4 1,2

1.1

2 3

6 7

9

8.1

8.2

8

4

A

11

----

FCU1 FCU2

FCUn

10 19

23

B

23.1

----

11

----

FHL1 FHL2

FHLn

----

17

22

Código

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2

3

4

6

Descripción

Manómetro

Válvula de seguridad

Placa intercambiadora de calor

()

Purgador

P_i: Bomba recirculadora en la unidad

Filtro en forma de

Y

Válvula de cierre (no suministrada)

Panel de control

Código

7

8

8.1

8.2

9

10

11

17

19

23

23.1

FHL 1…n

FCU 1...n

NOT

A

Descripción

Válvula de llenado (no suministrada)

Depósito de equilibrio (no suministrado)

Purgador

Colector (no suministrado)

Válvula de bypass (no suministrada)

SV2:válvula de 2 vías (no suministrada)

Suelo radiante (no suministrado)

Fancoil (no suministrado)

El volumen del tanque de equilibrio (8) debe ser mayor que 40L (para una unidad de 5~9kW, mayor que 20L). La

El panel de control (4) debe colocarse en la habitación donde se instalan los circuitos de suelo radiante y las

cuando la temperatura ambiente alcance la temperatura deseada.

Funcionamiento de las bombas

La bomba (1.8) y (10) funcionará cuando se solicite calefacción de

A y/o B. La bomba (23.1) funcionará cuando la temp. am-

para lograr la temperatura del agua deseada.

8.8 Aplicación

8

calor, el ACS proviene de la bomba de calor y el kit de energía solar.

26

1

1.6

1.7

1.5

1.8

1.3

1,4 1,2

1.1

2 3

18

27

6 7

8.1

8.2

8

9

4

10

12.1

12.1

12

13

12.3

12.2

11

----

14

15

16

FHL1 FHL2

FHLn

----

17

23

Código

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2

3

4

6

7

8

8.1

8.2

Descripción

Manómetro

Válvula de seguridad

Placa intercambiadora de calor

(

Purgador

P_i: Bomba recirculadora en la unidad

Filtro en forma de Y

Válvula de cierre (no suministrada)

Panel de control

Válvula de llenado (no suministrada)

Depósito de equilibrio (no suministrado)

Purgador

Código

9

10

11

12

12.1

12.2

12.3

13

14

15

16

17

18

FHL 1…n

26

27

/

NOT

A

Descripción

Colector (no suministrado)

Depósito de ACS (no suministrado) Purgador

Resistencia del depósito

T5: Sensor de temperatura

Grifo de agua caliente (no suministrado)

P_d: Bomba ACS (no suministrada)

Válvula de 1 vía (no suministrada)

Válvula de bypass (no suministrada)

SV1: Válvula de 3 vías (no suministrada)

Suelo radiante (no suministrado)

Kit de energía solar (no suministrado)

P_s: Bomba solar (no suministrada)

/

El volumen del tanque de equilibrio (8) debe ser mayor que 40L (para una unidad de 5~9kW, mayor que 20L). La vál-

independiente e instalarla en la puerta.

-

-

ACS durante el funcionamiento del kit de energía solar.

NOT

A

9 VIST

A DE LA UNIDAD

eléctricas y el compartimento hidráulico.

Puerta 1

Da acceso al del compresor

, a las

Puerta 1

Puerta 2

Para acceder al compartimento

12

1

5/7/9kW

12/14/16kW

24

ADVERTENCIA

antes de sacar las puertas 1 y 2.

Los componentes dentro de la unidad pueden estar calientes.

procedimiento al contrario. Evite lesiones en las manos.

9.2 Componentes principales

9.2.1 Módulo hidráulico

12/14/16kW

1

9

6.3

10

6.4

11

13

14

12

2

6.5

4

5

7

8

3

6.1

6.2

5/7/9kW

9

3

10

4

1

7

6.1

6.2

11

8

12

14

13

25

Código

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Descripción

Purgador

Sensor de presión

Sensores de temperatura

Manómetro

Bomba recirculadora

Placa intercambiadora de calor

Válvula de seguridad

9.2.2 Diagrama del sistema hidráulico

Código

1

2

3

5

7

8

9

10

11

5

7

2

1

15,3

9

T2B

TW_out

T2

TW_in

T1

3

15.2

15.1 1

1

13 8

Descripción

Purgador

Descripción

El aire que queda en el circuito de agua se elimina automáticamente

del circuito de agua.

Proporciona capacidad de calentamiento adicional cuando la capaci-

-

sión: 2L en unidades de 5/7/9kW y 5L en unidades de 12/14/16kW.)

/

/

Cuatro sensores de temperatura determinan la temperatura de agua

y refrigerante en varios puntos del equipo.

6.1-T2B; 6.2-T2; 6.3-T1(opcional); 6.4-TW_out; 6.5-TW_in

/

Proporciona lectura de la presión del circuito de agua.

Detecta el caudal de agua para proteger el compresor y la bomba

Hace que circule agua en el circuito de agua.

/

y descargando el agua del circuito de agua.

10

Recipiente de agua con calentador de agua

(opcional)

Manómetro

Bomba recirculadora

Placa intercambiadora de calor

12

14

Código

12

13

14

15.1

15.2

15.3

16

17

2

1

/

16 17

T1

Descripción

Válvula de seguridad

Aislante térmico

Aislante térmico

Aislante térmico

Sensores de temperatura: TW_in;TW_out;T2B;T2;T1 (opcional)

26

NOT

A

PCB A

PCB A

PCB C (parte trasera

PCB B, solo para unidades

de 3 fases)

PCB B Placa de control principal del módulo hidráulico

5/7/9kW

Placa de control principal del módulo hidráulico

PCB B

12/14/16kW

27

9.3.1 Placa de control principal del módulo hidráulico

Código

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Monofásico 5/7/9kW

Monofásico 12/14/16kW

Trifásico 12/14/16kW

Descripción

(P_o)/

5

27

26

25

24

23

22 21 20 19 18 17 16 15

1234 67

8

9

10

13

11

14

12

28

9.3.2 Unidades monofásicas de 5/7/9kW

1) PCB A,

Código

1

2

3

4

5

Descripción

2) PCB B, Placa de control principal

Código

6

7

8

9

/

Descripción

/

9

8

6

4

5

7

123

132

16

7

654

8

9

10

11

12

13

14

15

1718192021222326 25 24

27

28

29

Código

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Sensor de temperatura del puerto de descarga

Sensor de temperatura del puerto de entrada

9.3.3 Unidades monofásicas de 12/14/16 kW

1)

PCB A,

Código

1

2

3

4

5

6

7

Puerto de entrada P para el módulo (P)

Código

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Puerto de comunicación con el panel de control

Pantalla digital (DSP1)

(opcional)

Puerto para aislamiento térmico del compresor

Código

8

9

10

11

12

13

14

Puerto de salida P del Módulo PFC (P_1)

Puerto entrada para PFC inductancia L_1(L_1)

Puerto entrada para PFC inductancia L_2(L_2)

CN9

1

14

13

12

11

10

3

4

5

6789

2

30

Código Descripción Código Descripción

1

-

15

2

Puerto para el sensor de temperatura de entrada

16

3 17

Puerto para aislamiento térmico del compresor

4 18

Puerto para aislamiento térmico del chasis

5

19

6

Puerto de comunicación con el panel de control

20

7 21

8

22

9 23

10 24

11 25

12 26

13 27

14

2) PCB B, Placa de control principal

9.3.4 Unidades trifásicas de 12/14/16 kW

1) PCB A,

1

SW3

CN300

CN1

1

SW4

2

ON

ON

3 12

ON

ON

3

12 34 5 6 7 8 9 10

11

13

14151617

19

20

21

22

23

24

25

26

27

18

12

31

Código

1

2

3

4

5

6

7

8

9

Descripción

2) PCB B, Placa de control principal

PCB A

Código

1

2

3

4

5

6

7

8

9

10

11

12

13

Descripción

Puerto de control de comunicación con el

Código

14

15

16

17

18

19

20

21

22

23

24

25

/

Descripción

Puerto de salida para bobina de contactor P_line

(opcional)

/

9

76543

1

2

8

DIS1

134567

12

1415161718192025 212223

2

24

8

9

10

11

13

32

Código

1

2

3

4

5

6

PCB C

Descripción

Alimentación L3(L3)

Alimentación L2(L2)

Alimentación L1(L1)

Código

7

8

9

10

11

/

9.3.5 Piezas de control para la resistencia auxiliar(Reservado)

Código

1

2

3

4

5

6

Descripción

Filtrado L1 (L1')

Filtrado L2 (L2')

Filtrado L3 (L3')

/

Monofásico 12/14/16kW

T

rifásico 12/14/16kW

Descripción

Protector térmico automático

Protector térmico manual

-

Código

1

2

3

4

5

Descripción

Protector térmico automático

Protector térmico manual

-

CN32 CN38

CN37

CN36

CN39

CN31

CN30

CN18

CN19

11

1

2

3

4567

8

9

10

1234

5

1234

5

6

33

9.4 T

uberías de agua

T

odas las longitudes y distancias de las tuberías se han tomado en consideración.

Requisitos

(solo para instalaciones con acumulador de agua caliente sanitaria) . El cable

del sensor de temperatura suministrado con el acumulador de agua caliente

-

damos instalar la válvula de 3 vías y el acumulador de agua caliente lo más

cerca posible de la unidad.

NOT

A

Válvula

Longitud del cable del sensor de

temperatura menos 2 metros

Si la instalación está equipada con depósito de

ACS (no suministrado), consulte el manual del depósito de ACS.

Manual de usuario e instalación Si no hay glicol (anticongelante) en el sistema, y hay un fallo en la fuente de alimenta-

NOTA

partes del círculo de agua.

9.4.1 Comprobación del circuito de agua

1

1.6

1.5

1.7

9

1.8

1.3

1,4 1,2

1.1

2 3

6 7

8.1

8.2

8

4

10

11

----

FHL1 FHL2

FHLn ----

17

34

Volumen de agua ≤72 L(b)

Volumen de agua >72 L(b)

Acciones necesarias:

• Debe aumentar la pre-presión, calcule acorde

la sección "Cálculo de la pre-presión del vaso de

• Compruebe si el volumen de agua es menor

Acciones necesarias:

• Debe aumentar la pre-presión, calcule acorde

la sección "Cálculo de la pre-presión del vaso de

• Compruebe si el volumen de agua es menor

para la instalación.

Antes de proseguir con instalación de la unidad, compruebe los siguientes:

Siempre use material que sea compatible con el agua usada en el sistema y con los materiales usados en la unidad.

Cuide que componentes instalados en las tuberías puedan soportar la presión del agua y la temperatura.

durante el mantenimiento.

Los purgadores de aire se deben instalar en todos los puntos altos del sistema. Los purgadores se debe ubicar en puntos de

fácil acceso para el mantenimiento. Dentro de la unidad hay instalado un purgador de aire automático. Compruebe que este

purgador no esté muy apretado para que continúe saliendo el aire automáticamente del circuito de agua.

9.4.2 Comprobaciones del volumen de agua y la pre-presión del vaso de expansión

tiene una presión por defecto de 1,5 bar. Para asegurar el funcionamiento correcto de la unidad, es posible que sea necesario

volumen total de agua interna de la unidad.

NOTA

En la mayoría de las aplicaciones este volumen de agua mínimo tendrá un resultado satisfactorio.

En procesos de más intensidad o en habitaciones con una alta carga de calor puede necesitarse un volumen de

Cuando la circulación en cada circuito de calefacción es controlada por válvulas de control remoto, es importante

que este volumen mínimo de agua se mantenga incluso si todas las válvulas están cerradas.

Diferencia de

altura de la

instalación (a)

≤12 m

>12

m

menos que la unidad se encuentre en el punto más alto del sistema, en cuyo caso la diferencia de altura de instalación se

considera nula.

Para unidades monofásicas 12~16kW y trifásicas 12~16kW, este valor es 72L, para unidades 5~9kW, este valor es 30 L.

Cálculo de la pre-presión del vaso de expansión

Pg(bar)=(H(m)/10+0.3) bar

Comprobación del volumen máximo de agua permitido

35

Pg(bar)=(H(m)/10+0.3) bar

adicional:

V1=0.0693*V agua/ (2.5-Pg)-V0

Vwater es el volumen de agua en el sistema, V0 es el

(10~16kW

,V0=5L, 5~9kW,V0=2L).

9.4.3 Conexión del circuito de agua

-

to a la entrada y salida de agua.

PRECAUCIÓN

Cuide de no deformar las tuberías de la unidad usando

la tubería puede causar un mal funcionamiento de la

unidad.

Si el aire, la humedad o el polvo entra en el agua del circui-

to, pueden ocurrir problemas. Por tanto, siempre tenga en

cuenta lo siguiente cuando conecte el circuito de agua.

Use solo tuberías limpias.

quite las rebabas

-

vés de la pared para impedir que entre polvo y suciedad.

-

nes como las temperaturas del sistema.

Cuando use tuberías metálicas sin cobre, asegúrese de

aislar ambos materiales uno de otro para evitar corro-

sión galvánica.

El cobre es un material suave,

use las herramientas apropia-

das para conectar el circuito

de agua. Las herramientas

incorrectas pueden dañar las

tuberías.

NOT

A

La unidad solo se usa en un sistema cerrado de

agua. La aplicación en un circuito de agua abierto

tubería de agua:

-

en el circuito de agua interno de la unidad.

Al usar la válvula de 3 vías en el circuito de

-

tre el circuito de ACS y el circuito de agua para

suelo radiante.

Cuando se usa la válvula de 2 ó 3 vías en el

-

do de cambio de formato de la válvula debe ser

inferior a 60 segundos.

Determine para la pre-presión calculada (Pg) el

Compruebe que el volumen total de agua en todo el

circuito de agua es inferior a este valor. Si este no es el

muy pequeño para la instalación.

Presión (bar)

2.8

2.3

20 70 120 170

en el sistema

A1 Sistema sin glicol para unidades monofásicas de

12~16 kW y trifásicas de 12~16 kW

A2 Sistema sin glicol para unidad 5/7/ 9 kW

:

punto más alto en el circuito de agua. El volumen total

-

:

La unidad (16kW) está instalada en el punto más alto

en el circuito de agua. El volumen total de agua en el

circuito de agua es de 150 L.

Resultado:

Como 150 L

es superior a 72 L, la pre-presión debe

disminuir (ver la tabla arriba).

La pre-presión requerida es de: Pg(bar) =

(H(m)/10+0.3) bar = (0/10+0.3) bar = 0.3 bar

-

Como el volumen total de agua (150 L) está por de-

Cuando se requiera cambiar la presión de presión por

directrices:

-

sión llevará a un mal funcionamiento del sistema. la

-

adicional.

1.8

1.3

0.8

0.3

A2

A1

36

Calidad del

glicol%

Punto de

congelación/Υ

-

cidad refrigeración

la potencia

Resistencia

agua

caudal del agua

0

10

20

30

40

50

1.000

0.984

0.973

0.965

0.960

0.950

1.000

0.998

0.995

0.992

0.989

0.983

1.000

1.1

18

1.268

1.482

1.791

2.100

1.000

1.019

1.051

1.092

1.145

1.200

0.000

-4.000

-9.000

-16.000

-23.000

-37.000

9.4.4 Protección anti-hielo del circuito de agua

-

T

odas las partes hidrónicas internas están aisladas para reducir la pérdida de calor. También se debe agregar aislamiento a las

tuberías de la instalación.

Cuando la temp. del agua en el sistema desciende a un cierto valor, la unidad calentará el agua, ya sea usando la bomba de

-

En caso de un fallo de alimentación, las características anteriores no protegerían la unidad contra la congelación.

Dado que podría producirse un corte de corriente cuando la unidad está desatendida, el proveedor recomienda el uso de líqui-

do anticongelante en el sistema de agua. Consulte "Precauciones: Uso de glicol".

-

ción de glicol como se indica en la siguiente tabla.

Cuando se añade glicol al sistema, el rendimiento de la unidad se verá afectado. El factor de corrección de la capacidad de la

unidad, el caudal y la pérdida de carga del sistema se indica en la siguiente tabla.

Etilenglicol

Propilenglicol

Calidad del

glicol/%

0

10

20

30

40

50

-

cidad

refrigeración

1.000

0.976

0.961

0.948

0.938

0.925

potencia

1.000

0.996

0.992

0.988

0.984

0.975

Resistencia

agua

1.000

1.071

1.189

1.380

1.728

2.150

caudal de agua

1.000

1.000

1.016

1.034

1.078

1.125

Punto de

congelación/Υ

0.000

-3.000

-7.000

-13.000

-22.000

-35.000

ADVERTENCIA

Las concentraciones mencionadas en la tabla anterior no evitan el hielo, pero sí evitarán que se reviente el sistema

hidráulico.

37

NOTA

PRECAUCIÓN

Uso de glicol

Use glicol para las instalaciones con un

depósito

de ACS: Solo el propilenglicol

en la 5ta edición de la lista "Productos

Si hay demasiada presión al usar glicol,

conecte la válvula de seguridad a una

Corrosión del sistema debido a la glicol

El glicol libre se volverá ácido si entra en contacto con

-

de corrosión galvánica que causan un gran daño al

sistema. Es de gran importancia:

Si el tratamiento del agua es correcto y ha sido

controlado por un especialista.

El glicol con inhibidores de corrosión se selecciona

para contrarrestar los ácidos formados por los glico-

Que en caso de una instalación con un depósito de

ACS, solo el uso de propilenglicol está permitido. En

otras instalaciones el uso de etilenglicol es correcto.

de corrosión tienen un tiempo de vida limitado y contie-

ne silicatos que pueden corroer o enchufar el sistema.

de glicol ya que puede provocar la precipitación de

ciertos elementos en el inhibidor de corrosión del

glicol.

Asegurarse de que el glicol es compatible con los

Manténgase seco

NOT

A

T

enga en cuenta la propiedad higroscópica

del glicol. Absorbe la humedad del ambiente.

aumentará su concentración de agua. La

concentración de glicol es entonces más

glicol y evitar su evaporación.

También consulte "10.3 Comprobaciones antes del

funcionamiento/ Comprobaciones antes del arranque

inicial"

9.5 Añadir agua

Conectar el suministro de agua al puerto de llenado

y abrir la válvula.

Asegúrese de que la válvula de purga de aire está

abierta (al menos 2 vueltas).

Llene con agua hasta que el manómetro indique una

tanto como sea posible usando las válvulas de purga

de aire. El aire en el circuito de agua puede provocar

un mal funcionamiento de la resistencia eléctrica

plástico en el purgador en la

parte superior de la unidad

cuando el sistema está funcio-

nando.

Abra el purgador, mué-

completas para sacar

el aire del sistema.

38

NOT

A

Durante el llenado, puede que no sea posible sacar todo el aire del sistema. El aire que quede saldrá a través de las

válvulas de purga de aire automáticas durante las primeras horas de funcionamiento del sistema. Puede que sea nece-

sario un llenado adicional de agua.

La presión de agua indicada en el manómetro variará en dependencia de la temperatura del agua (presión más alta

a mayores temperaturas del agua). Sin embargo, en todo momento la presión de agua debe permanecer por encima

de 0.3 bar para evitar la entrada de aire en el circuito.

Puede que la unidad drene mucha agua a través de la válvula de descarga de temperatura y presión.

9.6

Aislamiento de la tubería de agua

T

odo el circuito de agua incluidas las tuberías debe estar aislado para evitar la condensación durante el modo refrigeración y

grosor de los materiales de sellado debe ser al menos de 13 mm con conductividad térmica 0.039 W/mK para evitar el hielo en

9.7 Cableado

ADVERTENCIA

-

-

nes que se relacionan a continuación.

equipo.

Asegúrese de instalar el interruptor diferencial (30mA) De lo contrario puede causar descargas eléctricas.

Asegúrese de instalar los fusibles o interruptores magnetotérmicos necesarios.

especialmente en el lado de alta presión.

eléctrica) para evitar tener que abrir el interruptor diferencial innecesariamente.

NOTA

El interruptor diferencial debe ser de alta velocidad 30mA

(<0.1 s).

del factor de potencia, sino que también puede causar un calentamiento anormal del condensador debido a las ondas de

9.7.2 Cableado - Resumen

La ilustración a continuación muestra el cableado necesario durante la instalación. Consulte también "8.

39

21

3

4

5

6

7

8

9

10

11

12

13

14

0

0

15

16

17

18

19

20

A

B

C

DE

F

G

H

I

J

K

l

M

N

N

N

N

N

2

1

3

4

5

6

7

8

9

10

11

21

22

12

13

14

0

0

15

16

17

18

19

20

A

B

C

D

E

F

G

H

I

J

K

l

M

N

N

N

N

N

N

12/14/16kW

5/7/9kW

40

Fig.

1

2

3

4

5

9

10

11

12

13

15

16

Descripción

Cable de comunicación del kit de energía solar

Cable del panel de control

Cable del termostato ambiente

Cable de control de la caldera

Cable del sensor de temperatura

T1B

Cable de control de la bomba de ACS

Cable de control de la válvula de 2 vías

Cable de control de la válvula de 3 vías

Cable del sensor T5

Cable de control de la resistencia del depósito ACS

Cable de alimentación para el calentador posterior

AC/DC

AC

AC

AC

/

DC

AC

AC

AC

DC

AC

AC

AC

Cantidad cables necesarios

2

5

2 ó 3

2

2

2

2

2 ó 3

2

2

200mA

200mA

200 mA (a)

200mA

(b)

200 mA (a)

200 mA (a)

200mAC

(b)

200 mA (a)

31A (Monofásico)

15A (Trifásico)

14A (Monofásico)

6A (Trifásico)

Código

A

B

C

D

E

F

G

H

Descripción

Kit de energía solar (no suministrado)

Panel de control

T

ermostato ambiente (no suministrado)

Caldera (no suministrada)

P_s: Bomba solar (no suministrada)

Código

J

K

L

M

P

Descripción

P_d: Bomba ACS (no suministrada)

SV2: Válvula de 2 vías (no suministrada)

SV1: Válvula de 3 vías para depósito de ACS

(no suministrada)

Depósito de agua caliente sanitaria

Resistencia del depósito

Contactor

Suministro eléctrico

(a) Sección mínima del cable

AWG18 (0,75 mm para el panel de control.

(b) El cable del sensor de temperatura se entrega con la unidad: Si la corriente de la carga es elevada, se necesita un

contactor de CA.

NOTA

cable del sensor de temperatura y el cable del panel de control.

debe controlar a través del contactor AC.

"AHS1" "AHS2", "A1" "A2", "R1" "R1" y "DTF1" "DTF2", los puertos de terminal cableado solo ofrecen la señal del interruptor.

Consulte la imagen de 9.7.6 para obtener la posición de los puertos en la unidad.

comparten el puerto de control.

Monofásico 12~16kW /

Trifásico 12~16kW

Código Descripción

9 Entrada de agua

10 Salida de agua

1

2

4

5

7

8

9

10

3

6

41

ADVERTENCIA

Código

1

2

3

4

5

Descripción

Salida de agua

Entrada de agua

Monofásico 5/7/9 kW

Guías para la instalación eléctrica

•

•

•

•

• Se ruega consulte el Manual de usuario e instalación del depósito de agua caliente sanitaria

Asegure el cableado como se

•

la tapa frontal.

•

Consulte el diagrama eléctrico para el tendido de los cables (el diagrama eléctrico está ubicado en la parte trasera de la

puerta 2.

•

9.7.3 Precauciones del cableado de alimentación

• Use un terminal para cable para conectar el cableado de alimentación al bornero. En caso que no se pueda usar debido a

-

-

sobrecalentamiento).

•

tornillo y evitar el apriete correcto.

•

•

•

2

1

3

4

5

42

NOT

A

LPS

1

LPS

L1 L2 L3

1

LPS

FUSE

AB C

5

L1 L2 L3

LPS

4

Unidad (kW)

Capacidad resist.

Monofásico T

rifásico

3 4.5

Amperios mín. circuito

(MCA)

Sección del cable

(mm

2

)

220-240VAC

14.3

20

4

380-415VAC

6.0

10

2.5

Unidad (kW)

Monofásico T

rifásico

5/7/9 12~16 12~16

20 30 15

Sección del cable

(mm

2

)

464

NOTA

ADVERTENCIA

Monofásico

•

El interruptor diferencial debe ser un interruptor mangnetotérmico de alta velocidad para 30 mA

(< 0,1 s).

9.7.5 Conexión de la fuente de alimentación de la resistencia auxiliar

.(Esta sección está desti-

nada sólo a los modelos que contienen resistencia auxiliar).

Requisitos del circuito de alimentación y del cable

-

de ACS.

Este circuito de alimentación debe estar protegido con los dispositivos de seguridad necesarios según la normativa local.

Seleccionar el cable de alimentación homologado según las regulaciones locales. Para más información sobre el rango de

(Trifásico)

Trifásico

El interruptor diferencial debe ser un interruptor mangnetotérmico de alta velocidad para 30 mA (< 0,1 s).

43

9.7.6 Conexión de otros componentes

Unidad 5~9kW

Unidad 12~16kW

Código

1

2

3

4

5

6

7

Entrada solar

Alarma remota

SV2

SV1

Cierre remoto

Bomba_C / Bomba_D

T

ermostato ambiente

Descripción Código

8

9

10

11

12

13

14

Descripción

Fuente de calor adicional

Entrada de señal del interruptor de retorno

Señal de desescarche

Control cableado

Los puertos proporcionan la señal de control a la carga. Dos tipos de puertos de señal de control:

Tipo 1: Contacto seco sin tensión.

Tipo 2: Proporciona 220V de tensión. Si la corriente de carga es <0.2A, la carga puede conectarse al puerto directamente.

Si la corriente de carga es >=0,2A, es necesario conectar el contactor de CA para la carga.

Carga

25

R1

26

R2

En funcio-

namiento

Tipo 1

Suministro eléctrico

7

8

5 3

6 4

1

2

4

TBH

A1

A2

15

Contactor

Tipo 2

a distancia, válvulas de 2 y 3 vías, bomba, resistencia del

1) Kit de energía solar

1

SL1

2

SL2

Sección del cable (mm

2

)

220-240V

AC

0.2

0.75

1

A

2

B

3

X

4

Y

5

E

6

P

7

Q

8

E

9

M1

10

M2

1

SL1

2

SL2

3

C

4

TBH

5

N

6

ON

7

OFF

8

PBo

9

N

10

HT

25

AHS1

33

DFT1

34

DFT2

35

HBK1

36

HBK2

37

P_d

38

N

39

N

40

L1

26

AHS2

27

R1

28

R2

31

H1

32

H2

29

11

N

12

A1

24

A2

23

N

22

PAs

21

N

20

IBH1

19

N

18

SV2

13

H

14

L1

15

N

16

PAc

17

N

CN5 CN7 CN8 CN9

CN9 CN11

CN19

CN10

CN10 CN15

CN16

CN17

14

5

13

1

7

8

6

6

4

3

10

2

XT6 XT7 XT8 XT9

CN18

CN20

CN13 CN14

L1

N

30

912

11

14

56

1

7

8

6

4

3

10

29

13

1

A

2

B

3

X

4

Y

5

E

6

P

7

Q

8

E

9

M1

10

M2

25

R1

29

PBd

30

N

31

DTF1

32

DTF2

26

R2

27

ASH1

28

ASH1

CN1

CN3

XT8

CN4

CN5 CN7 CN8 CN9 CN10

1

SL1

2

SL2

3

C

4

TBH

5

N

6

ON

7

OFF

8

PBo

9

N

10

HT

11

N

12

A1

24

A2

23

N

22

PAs

21

N

20

IBH1

19

N

18

SV2

13

H

14

L1

15

N

16

PAc

17

N

XT6 XT7

44

22

P_s

23

Salida de la señal de control

Amperios mín. circuito (MCA)

Sección del cable (mm

2

)

T

ipo de señal del puerto de control

2)

Alarma remota:

12

A1

24

A2

Sección del cable (mm

2

)

T

ipo de señal puerto de control

a) Procedimiento

Conectar el cable a los terminales correctos como se

muestra en el diagrama.

220-240VAC

0.2

0.75

Tipo 2

Señal pasiva

0.2

0.75

Tipo 1

3) Válvula de 2 vías SV2:

18

SV2

19

Sección del cable (mm

2

)

T

ipo de señal puerto de control

NOT

A

(normalmente cerrada).

220-240V

AC

0.2

0.75

Tipo 2

a) Procedimiento

Conecte el cable a los terminales correctos como se

4) Válvula de 3 vías SV1

6

7

21

SV1

Método 1

Sección del cable (mm

2

)

Tipo de señal puerto de control

6

7

21

SV1

Método 2

NOT

A

Antes del cableado, lea cuidadosamente el Manual

de uso

e instalación para la válvula de 3 vías e insta-

-

se de conectarla al número de terminales correctos.

220-240VAC

0.2

0.75

Tipo 2

a) Procedimiento

Conecte el cable a los terminales correctos como se

5) Parada remota:

9

10

M1 M2

6) Bomba del circuito del depósito P_d y mez-

cladora P_c:

16

P_c

17

PUMPC

29

P_d

30

PUMPC

37

P_d

38

PUMPC

45

NOT

A

Para las unidades 5/7/9 kW, el número del termi-

nal es 37 y 38. Para las unidades 12/14/16 kW

, el

número del terminal es 29 y 30.

Sección del cable (mm

2

)

Tipo de señal del puerto de control

a) Procedimiento

Conecte el cable a los terminales correctos como se

220-240VAC

0.2

0.75

Tipo 2

7) Termostato ambiente:

13

H

CALEFAC-

14

L1

RT1

3

C

-

GERA-

-

Método A:

13

H

RT1

14

L1

3

C

-

Método C:

13

H

14

L1

RT1

3

C

-

Método B:

RT1

RT

-

-

13

H

HEAT

3

RT2

15

C

Método A:

13

H

RT2

L

L

3

13

H

15

C

RT2

Método C:

Sección del cable (mm

2

)

NOT

A

dependiendo del tipo de termostato ambiente.

3

R

T2

15

C

Método B:

L

220-240VAC

0.2

0.75

L

la tensión al conector RT directamente. El puerto "14 L1"

proporciona la tensión de 220V al conector RT. El puerto

"14 L1" se conecta desde el puerto de alimentación princi-

pal de la unidad L de la fuente de alimentación monofási-

ca, el puerto L2 de la fuente de alimentación trifásica.

eléctrica al conector RT directamente. L se conecta desde

el puerto de alimentación principal de la unidad L de la

fuente de alimentación monofásica, el L2 de la fuente de

alimentación trifásica.

L1 L2 L3

Trifásico

46

R

T puede controlar la calefacción y la refrigeración individualmente. Cuando el módulo hidráulico está conectado con un termostato

refrigeración.

:

NOT

A

a válido, la unidad funciona solo de acuerdo con T1.

-

NOT

A

termostato ambiente.

La fuente de alimentación de la máquina y el termostato de ambiente deben conectarse a la misma línea neutra y a

la misma línea de fase (L2) (solo para la unidad trifásica).

a) Procedimiento

8) Resistencia del depósito de

ACS:

4

TBH

5

DE ACS

Sección del cable (mm

2

)

T

ipo de señal del puerto de control

220-240VAC

0.2

0.75

Tipo 2

ACS depende de la aplicación. Este cableado solo es

necesario cuando se instala el acumulador de ACS. La

unidad solo envía una señal de encendido/apagado a la

resistencia del depósito de ACS. Se necesita un interruptor

magnetotérmico adicional y un terminal para suministrar

energía a la resistencia del depósito de ACS.

-

a) Procedimiento

Conecte el cable a los terminales correctos como se

47

220-240VAC

0.2

Sección del cable (mm

2

) 0.75

T

ipo de señal del puerto de control

Tipo 2

220-240VAC

0.2

Sección del cable (mm

2

) 0.75

T

ipo de señal del puerto de control

Tipo 2

31

H1

39

32

H2

39

13) Para salida de la señal de desescarche

33

DFT1

34

DFT2

Sección del cable (mm

2

)

T

ipo de señal del puerto de control

14) Control cableado:

220-240VAC

0.2

0.75

Tipo 1

NOT

A

Este equipo soporta el protocolo de comunicación

Tipo de cable

Sección de cable (mm

2

)

Cable apantallado 5 hilos

0,75~1,25

50

9) Fuente de calor adicional:

27

AHS1

28

AHS2

Para unidades 5/7/9 kW, el número del terminal es 25 y 26.

Atco: Protector térmico de auto reinicio

Debe estar conectado al protector térmico!

12) Kit de resistencia auxiliar externa (opcio-

nal) (solo para la unidad de 5/7/9kW).

10) Bomba de circulación exterior P_o:

a) Procedimiento

1

1) Entrada de señal del interruptor de

retorno (solo para la unidad de 5/7/9 kW,

reservado):

8

P_o

9

Conecte el cable a los terminales correctos como se

-

rre de cable para asegurar que no estén tensados.

35

HBK1

36

HBK2

EABXY

12345

XT6

ABXYE

12345

MODBUS

E

A+

B-

48

T1s

Curva

-20 -15 -10 -5 0 5 10 15 20 25 35

1

2

3

4

5

6

7

8

38

35

33

35

33

31

29

29

37

34

33

34

32

30

29

28

36

34

32

33

32

30

28

28

36

33

32

32

31

29

28

27

35

32

31

31

30

28

27

26

34

32

31

31

30

28

27

26

33

31

31

30

29

27

27

25

33

31

30

29

29

27

26

25

32

30

30

28

28

26

26

24

32

30

30

28

28

26

26

24

32

30

30

28

28

26

26

24

1

2

3

4

5

6

7

8

55

55

55

50

50

45

45

40

54

54

53

49

49

44

44

39

54

52

51

49

47

44

42

39

53

51

49

48

46

43

41

38

52

50

47

47

45

42

40

37

52

49

45

47

44

42

39

37

51

47

44

46

42

41

37

36

51

46

42

46

41

41

36

36

50

45

40

45

40

40

35

35

50

45

40

45

40

40

35

35

50

45

40

45

40

40

35

35

puerto E.

a) Procedimiento

10 ARRANQUE

Y CONFIGURACIÓN

-