HTW MINI VRF V10 UNIDAD EXTERIOR Guía de instalación

- Tipo

- Guía de instalación

MINI VRF V10

OUTDOOR UNIT

HTW-V200WV2RN1V10 | HTW-V224WV2RN1V10

HTW-V260WV2RN1V10 | HTW-V280WV2RN1V10

HTW-V335WV2RN1V10

ES

EN

Por favor lea atentamente antes de usar este producto.

Please, read carefully before using the product.

Manual de Instalación

Installation Manual

ESPAÑOL

Manual de Instalación

MINI VRF V10

UNIDAD EXTERIOR

HTW-V200WV2RN1V10 | HTW-V224WV2RN1V10

HTW-V260WV2RN1V10 | HTW-V280WV2RN1V10

HTW-V335WV2RN1V10

3

PRECAUCIONES

No conecte el equipo a la alimentación principal directamente.

ADVERTENCIA

CONTENIDO PÁGINA

PRECAUCIONES ........................................................................................... 3

ACCESORIOS SUMINISTRADOS ................................................................4

INSTALLATION DE LA UNIDAD EXTERIOR ................................................5

INSTALACIÓN DE LA TUBERÍA DE REFRIGERANTE ...............................6

INSTALACIÓN ELÉCTRICA ........................................................................11

TEST RUNNING ...........................................................................................14

CONFIGURATION .......................................................................................14

PRECAUCIONES PARA EVITAR FUGAS DE REFRIGERANTE ...............14

CÓDIGOS DE ERROR .................................................................................15

ENTREGA DEL MANUAL ...........................................................................15

1. PRECAUCIONES

nacionales e internacionales.

BXY!?@Z?:[+!=X#""

la instalación.

Las precauciones descritas a continuación incluyen temas de

seguridad importante. Cumplir estas regulaciones rigurosamente.

#K"J\"#"

funcionamiento para comprobar que no hay problemas.

Seguir las indicaciones del manual de usuario sobre el uso y el

mantenimiento de la unidad por el cliente.

Apague la alimentación principal (disyuntor) antes de realizar el

de mantenimiento la unidad.

YT"VJ"&

instalación.

PRECAUCIONES

Instalación del nuevo refrigerante del aire acondicionado

B""G"$""^@v]"\"

x&#"\#"x{V&"T

"$""9KQ

"$""\#"""J\

"T#V"$""""

aceite de refrigeración no entren en el circuito de refrigeración.

Y"V""""$""""\&"$""

tamaños de las secciones de conexión de los puertos de carga de

la unidad principal y las herramientas de instalación son las del

"$""V

=Q""#T#"

"$""'^@-v

Y""Gx\"GV&#

H#"^@&#"$V"T"

#V@}"Gx#"T#

Q"#"""&#"%T#"G

tener dentro.

Pida a un técnico autorizado o a un profesional de instalación

eléctricas o incendios.

Desconecte el equipo o el disyuntor antes de realizar cualquier

eléctricas.

Conecte correctamente el cable de conexión.

Si el cable de conexión está mal conectado se pueden dañar las

piezas eléctricas.

tenga cuidado de no introducir gases ni otras sustancia que no sea

e. Si

se mezcla aire u otra sustancia con el refrigerante, la presión de gas

Si la unidad queda expuesta al agua o a la humedad antes de la

eléctricos.

cuidadosamente en

busca de daños.

cuidado al manipular las piezas.

manual de instalación.

eléctricas o incendios.

Cuando el aire acondicionado se instala en una habitación pequeña,

tome las medidas necesarias para asegurar que la concentración de

Instale el aire acondicionado de manera segura en un lugar donde la

base pueda sostener el peso adecuadamente.

contra un terremoto.

Si el aire acondicionado no se instala adecuadamente, pueden

Si el gas refrigerante derramado entra en contacto con el fuego, se

refrigerante.

Si hay fugas de refrigerante dentro de la habitación y hay cerca

fuentes de calor como una cocina, se pueden generar gases

La unidad se debe instalar teniendo en cuenta las regulaciones

Si el bornero de alimentación está dañado, debe ser sustituido por

dimensiones del espacio necesario para la correcta instalación de la

4

La temperatura del circuito puede ser alta, mantenga el cableado

J"G

!#\]+]+;#""

Z#\#"##

#"V"

Z##"x\"

"!VTJ"%$"%""#"T

H@"TT#}""

@"T""K"G

gas o agua, o al cable a tierra de la luz o del teléfono.

Cumpla con las regulaciones locales de electricidad durante los

"JK"

Zx\""##"V""K"

No instale el equipo en un lugar peligroso con riesgos de posibles

$

Si hay fugas de gas alrededor del aire acondicionado, y el gas

#""##"V"

Para los aparatos destinados a ser utilizados en altitudes superiores a

"}}x

2. ACCESORIOS

?#""="""&

Tubería de refrigerante

!"G%#""$""V

no puede ser utilizado.

B""&"J"

K$""$""V=T

tuerca abocardada que se encuentra en la unidad principal del aire

&G

Preparación previa a la instalación

Tenga cuidado con los siguientes puntos antes de la instalación.

Purga de aire

Y"#""VG

No utilice el refrigerante cargado en la unidad exterior para la

purga de aire.(El refrigerante para la purga de aire no está en la

unidad exterior)

Cableado eléctrico

@"J"\&

x\""x"""%"#"T"

en contacto con la carcasa ni otros elementos.

Lugar de instalación

Z"T#"#"##""

unidad exterior. Un lugar donde el ruido del funcionamiento y el aire

"V

Z"TKx#""$"V

Un lugar donde no se bloquee el paso.

?x""#\V

"TK$""

distancia aprox.

Q"##""#"

Un lugar donde el agua drenada no cause problemas.

PRECAUCIONES

Instale la unidad exterior en un lugar donde el aire de descarga no

esté bloqueado.

Cuando una unidad exterior está instalada en un lugar siempre

x#V$"""%

alto, asegure el equipo usando un conducto o un pantalla contra

V#"""$"V"

CANTIDAD

ACCESORIOS

DE INSTALACIÓN

FORMANOMBRE

1. Manual de instalación de la

unidad exterior

2. Manual de usuario de la

unidad exterior

3.Pipeta de condensados 1

4. Resistencia fin de bus

5. Tapón drenaje

6. Accesorio de conexión de las

tuberías frigoríficas

2

1

2

1

1

7) Detector de fugas de gas

9

especiales)

requisitos especiales)

los bordes

4) Cortador de tubos

5) Cuchillo

5

3. INSTALACIÓN UNIDAD EXTERIOR

3.1 Lugar de instalación

Por favor, mantenga el equipo alejado de los siguientes lugar, de lo

contrario puede provocar un mal funcionamiento:

Hay una fuga de gas combustible.

Hay mucho aceite (incluyendo aceite del motor).

Hay aire salado circundante (cerca de la costa).

Hay gas cáustico (el sulfuro, por ejemplo) existente en el

aire (cerca de una fuente termal).

Un lugar donde el aire expulsado hacia fuera de la unidad

exterior pueda llegar a la ventana de su vecino.

Un lugar en el que el ruido no interfiere a sus vecinos en la

vida cotidiana.

Un lugar demasiado débil para soportar el peso de la unidad.

Lugar desequlibrado.

Un lugar con una ventilación insuficiente.

Cerca de una central eléctrica o de equipos de alta frecuencia.

Instale la unidad interior, la unidad exterior, el cable de

Instale la unidad en un lugar que pueda ofrecer espacio

suficiente para su instalación y mantenimiento. No lo instale en

un lugar que tenga una elevada exigencia de silencio, como

una habitación.

alimentación y el cable de comunicación al menos a 1 m de

distancia del televisor o de la radio para evitar ruidos o

interferencias en la imagen.

PRECAUCIÓN

3.2 Espacio de instalación (Unidad:mm)

evitar interferencias en la imagen y el ruido en los aparatos

eléctricos. (Se puede generar ruido en función de las

condiciones bajo las cuales se genera la onda eléctrica,

incluso si se mantiene 1 metro).

Mantenga la unidad interior, la unidad exterior, el cable de

alimentación y el de comunicación de al menos 1 m

de distancia de las televisiones y radios. Esto es para

El aislamiento de las partes metálicas del edificio y el aire

acondicionado debe cumplir con la regulación de la Norma Nacional

de Electricidad.

Cuando instale la unidad exterior en un lugar que esté constante-

-

Instale la unidad de manera que los laterales que expulsan aire

No instale la unidad exterior en la pared.

operación de la boca de descarga se establece en ángulo recto

Viento

fuerte Viento

fuerte

Fig.2-2

La instalación en los siguientes lugares puede dar lugar a algunos

problemas.

Un lugar lleno de aceite de máquina.

Un lugar donde es probable que se generen ondas de radio

de alta frecuencia a partir de equipos de audio, soldadores y

equipos médicos.

3000

Stro

wind

Strong

wind

Fig.2

Fig.3-1

668 206

440

400

528

494

1558

1120

>300

>600

>300

>

0003

Fig.3-2

Fig.3-3

Fig.3-4

>3000 >1000 >6000 >4000 >300

>600

>3000

>300

Instalación de una sola unidad

Pared o obstáculo

Mantener

distancias

Salida aire

Entrada aire

Entrada aire

Conexión paralela de dos unidades o más

Conexión paralela de los lados delantero y trasero

Fig.3-6

Fig.4-1

Fig.3-5

>600

Fix with bolt

6

3.3 Traslado y montaje

El centro de gravedad de la unidad no se encuentra en su

centro físico, así que por favor tenga cuidado al levantarla.

Nunca sujete la unidad por la entrada de aire para evitar

que se deforme.

No toque el ventilador con las manos u otros objetos.

No incline la unidad más de 45 °, y nunca tumbarla horizontal-

-mente.

Haga una base de hormigón de acuerdo con las

epecificaciones de la unidad exterior (Consulte Fig.3-5).

Fijar los pies de la unidad con pernos con firmeza para

evitar que se csuelte en caso de terremoto o de fuerte

viento. (Consulte Fig.3-5)

4. INSTALACIÓN DE LAS TUBERÍAS

FRIGORÍFICAS

Compruebe que la diferencia de altura entre la unidad interior y

la unidad exterior, la longitud total de las tuberías de refrigerante,

y el número de las curvas cumplan con los siguientes

requisitos:

4.1

Tubería de regrigerante

PRECAUCIÓN

Por favor, preste atención para evitar que se dañen los

componentes mientras se realiza la conexión de las tuberías.

Para evitar que la tubería de refrigerante se oxide en el

interior durante la soldadura, es necesario usar nitrógeno, de

lo contrario el óxido puede bloquear el sistema.

Entrada para las conexiones frigoríficas y eléctricas

Los patrones de salida de conexiones que se pueden

seleccionar, son por la parte frontal y la lateral. En las siguientes

figuras se muestran las ubicaciones:

Tabl

a

4-1

da frontal Salida lateral

4.2 Detec

ción de fugas

Utilice agua jabonosa o detector de fugas para comprobar si todas

las soldaduras presenta fugas o no (Consulte Fig.4-2). Nota:

A es la válvula de de servicio de baja presión

B

es la válvula de servicio de alta presión

C y D es la conexión de tuberías entre las unidades interiores y

exterior.

PRECAUCIÓN

1. Salida lateral: cortar el agujero de la placa lateral. Se sugiere cortar

un trozo de la placa de metal de abajo para evitar la entrada de

ratones y que destruyan el cableado de la máquina.

2. Salida frontal: cortar el agujero de la placa frontal. Se sugiere cortar

un pedazo del lado derecho placa de metal para evitar la entrada de

ratones y que destruyan el cableado de la máquina.

3. Cableados: el cable eléctrico debe salir a través de los dos agujeros

de plástico de la placa, unirlos con las tuberías de refrigerante.

PRECAUCIÓN

Durante la instalación de la unidad exterior, prestar atención al

lugar de instalación y el patrón de drenaje;

Si el equipo está instalado en una zona alpina, el agua congelada

condensada bloqueará la salida de agua, por favor saque el tapón

de goma de la salida de agua de reserva. Si aún así no logra

satisfacer el drenaje de agua, por favor abrir las otras dos salidas

de agua pre-troqueladas.

Tapón elíptico Pipeta y junta de desagüe

NOTA

3.4 Drenaje

Todas las imágenes de este manual tienen el único propósito

explicativo. Pueden ser ligeramente diferentes del equipo que ha

adquirido (depende del modelo). La forma real prevalecerá.

Cuando se desee realizar un drenaje centralizado en un punto,

instalar la pipeta con su junta y los dos tapones elípticos para el

chasis, como se muestra en la Figura 3.6. Instale el tubo de

drenaje para completar la instalación del drenaje centralizado.

7

Fig. 4-2

DC

AB

Conexiones frigoríficas interiores

Conexiones frigoríficas

Fig. 4-3

4.3

Aislamiento térmico

Cortar

Realice el aislamiento térmico de las tuberías de líquido y gas por

separado. La temperatura de las tuberías del lado de gas y lado de

líquido es totalmente diferente, para evitar la condensación por favor

realizar el aislamiento térmico total.

El tubo de gas debe utilizar material de aislamiento de espuma

de células cerradas, con el ignífugo de grado B1 y con una

resistencia al calor de más de 120 ° C.

.

Cuando el diámetro exterior del tubo de cobre sea ≤ Φ12.7mm,

el espesor de la capa aislante debe ser de más de 15 mm;

Cuando el diámetro exterior del tubo de cobre sea ≥ Φ15.9mm, el

espesor de la capa aislante debe de ser de más de 20 mm.

Por favor, use materiales de aislamiento térmico unidos para

realizar el aislamiento térmico y sin espacio para las piezas de

conexión de los tubos de la unidad interior.

Cuerpo de la unidad Cinta

Tubería

4.4 Método de conexión

Selec

ción de las tubería

Tabl

a

4-2

/

DEF

GHI

$%&

'(

DEF

H

I

G

/////

$%&'(

Fig. 4-4

Código

Tubería principal

Tuberías

principales uds. Int

Tuberías uds.

Interiores

Distribuidores

Tubería entra la unidad exterior y el

primer distribuidor.

Tuberías entre distribuidores

Tubería del distribuidor a su unidad

interior

Nombre Definición

El primer método de conexión

El primer distribuidor

Unidad Exterior

Unidades

Interiores

Distribuidores frigoríficos intermedios

y finales

/Њ/

Fig. 4-5

1

1

1

1

1

1

$%

'

(

&

D

E

F

H

I

G

/ /

/

/

/

primer distribuidor

Unidades

Interiores

Unidad Exterior (Ejemplo modelo 260)

El segundo método de conexión

NOTA

Si la distancia entre el primer distribuidor y la última unidad

interior es más de 15 metros, elija el segundo método de

conexión.

La distancia entre la unidad interior y el distribuidor más cercano

debe ser inferior a 15m.

4.4 Diámetros de tubería de las unidades

interiores

Diámetro de la tubería principal, del distribuidor intermedio y

del distribuidor final.

1) Diámetros de tubería según la capacidad (Consulte la Tabla 4-3).

2) Ejemplo: En la Fig.4-5, la capacidad total aguas abajo de la

tubería L2 es de 45×2˙90, por lo que según la Tabla 4.4, el

diámetro de gas / líquido de L2 será˖Φ15.9 (5/8") / Φ9.5 (3/8").

$ψ

ŏ$ψ

ŏ$ψ

¢ ¢

FQZHN-03D

FQZHN-02D

FQZHN-01D

FQZHN-01D

ЊЊ

Tabla 4-3 Diámetros de tubería (L2 L5) y distribuidores (B E)

Gas Líquido Distribuidor

Tubería (mm)

Capacidad total

(kW) aguas

abajo (A)

¢ (5/8")

¢9.5 (3/8")

¢ (3/4")

¢9.5 (3/8")

¢9.5 (3/8")

(1/2")

(1 1/8")

Tabla 4-4 Diámetros de tubería principal (L1) y primer distribuidor (A)

4.5 Diámetros de tubería de la unidad exterior

¢ (7/8")

ŏ$ψ

Capacidad

total de la

ud. exterior

9H"G#"#

"G

TVGT

Gas

(mm) Gas

(mm)

BGT

(mm) BGT

(mm)

Primer

Distribuidor Primer

Distribuidor

9H"G#"#

"G

TVGT

NOTA

8

las unidades interiores, no se permite la conexión de bifurcación

adicional.

total diseñada de las unidades interiores a las que se conecta.

Si esta capacidad es mayor que la de la unidad exterior,

Método de conexión

Tabla 4-5

Unidad exterior

Unidad interior

Distribuidor

Gas

Soldadura o

Abocardado

Abocardado

Soldadura o

Abocardado

Soldadura o

Abocardado

Abocardado

Soldadura o

Abocardado

T

Capacidad

rango Capacidad

(HP)

Capacidad

rango

Capacidad

(HP)

Diferencia de altura máxima

(m)

Cuando la ud.

ext. está arriba

4.6. Ilustración

Cuando la ud.

La longitud

de

El primer distribuidor

Unidad interior

T

Cuando la capacidad total de las unidades interiores sea mayor que el

Cuando la capacidad total de las unidades interiores sea mayor o igual

arrancar las unidades interiores en diferentes momentos.

NOTA

Tamaños de tubería en la tubería de derivación

Diámetro de la tubería del conector en el cuerpo de la unidad exterior

Salida de aire de

4 lados 56~80

Salida de aire de

4 lados 28~45

montado en pared

22~45

Tipo conducto delgado

71

12.7

(Tuerca abocardada)

12.7

(Tuerca abocardada)

15.9

(Tuerca abocardada)

15.9

(Tuerca abocardada)

6.4

(Tuerca abocardada)

montado en pared 56 15.9

(Tuerca abocardada)

9.5

(Tuerca abocardada)

6.4

(Tuerca abocardada)

9.5

(Tuerca abocardada)

9.5

(Tuerca abocardada)

Salida de aire

unilateral 18~45 12.7

(Tuerca abocardada)

6.4

(Tuerca abocardada)

Salida de aire

unilateral 56 15.9

(Tuerca abocardada)

9.5

(Tuerca abocardada)

Baja presión

estática 18~45 12.7

(Tuerca abocardada)

6.4

(Tuerca abocardada)

Baja presión estática 56

15.9

(Tuerca abocardada)

9.5

(Tuerca abocardada)

Tipo conducto

A5

22~45

Tipo conducto

A5

56~140

12.7

(Tuerca abocardada)

6.4

(Tuerca abocardada)

Refrigerante

R410A

A (TIPO) Lado del aire (Φ) Lado líquido (Φ)

Tabla 4-6

(A: the total capacity of indoor units)

Tipo cassette de 4 vías

15~45

12.7

(Tuerca abocardada)

6.4

(Tuerca abocardada)

Tipo cassette

bidireccional 22~45

12.7

(Tuerca abocardada)

6.4

(Tuerca abocardada)

Tipo cassette

bidireccional 56~71

15.9

(Tuerca abocardada)

9.5

(Tuerca abocardada)

Tipo consola 22~45

12.7

(Tuerca abocardada)

6.4

(Tuerca abocardada)

Tipo suelo techo

36~45

12.7

(Tuerca abocardada)

6.4

(Tuerca abocardada)

Tipo suelo techo

56~160

15.9

(Tuerca abocardada)

9.5

(Tuerca abocardada)

Tipo suelo expuesto y

oculto 22~45

Tipo suelo expuesto y

oculto 56~80

12.7

(Tuerca abocardada)

6.4

(Tuerca abocardada)

15.9

(Tuerca abocardada)

9.5

(Tuerca abocardada)

15.9

(Tuerca abocardada)

9.5

(Tuerca abocardada)

Lado de conexión

de tubería

Diámetro de la tubería del conector de la u.exterior (mm)

Φ19.1 Φ9.53

Φ22.2

Φ9.53

Modelo (kW)

20-22.4

26-28

33.5

Tabla 4-7

Lado de gas Lado líquido

Φ22.2

Φ12.7

Tabla 4-8

Unidad exterior

(kW)

Capacidad de la

u. exterior

(caballos de

fuerza)

Cantidad

máxima de

u. interior

Capacidad total de

la unidad interior

(caballos de fuerza)

50%~130%

117

20

138

22.4

159

26

1610

28

33.5

12 20

de la capacidad de la unidad exterior.

La sobrecarga reduce la capacidad correspondiente.

La cabecera de bifurcación debe conectarse directamente con

9

Diferencia

de altura

Máximo

9

Long. real

(desde una ud. int. a su distribuidor

más cercano) (m)

Diferencia de

Ud. ext. arriba

ẇ

c t

T

L2+L3+L4+L5+f (El primer método de conexión)

o L3+L5+f (El segundo método de conexión)

Primer método de conexión

Unidad exterior

El primer distribuidor

del distribuidor más cercano)

Unidad interior

Diferencia de altura

entre uds. interiores

Fig.4-7

Los distribuidores interiores son a~f, para diferentes tamaños

los distribuidores de la unidad interior

10

Segundo método de conexión

Unidad exterior

Longitud máxima de la

El primer distribuidor

Unidad interior

4.7. Sacar la suciedad o el agua de la tubería

-

-

gerante de la unidad exterior.

4.8. Prueba de estanqueidad

Cargue con nitrógeno presurizado después de conectar las

prueba de estanqueidad.

cuando se aplique nitrógeno presurizado.

5. La prueba de estanqueidad nunca se debe realizar con

más cercano)

El primer distribuidor

4.10. Carga adicional de refrigerante

T

9

Diámetro

Carga de refrigerante

NOTA

PRECAUCIONES

se debe usar en la prueba de estanqueidad.

nitrógeno presurizado.

4.9. Purga del aire con la bomba de vacío

refrigerante para sacar el aire.

11

5. CABLES ELÉCTRICOS

PRECAUCIONES

las unidades interiores conectadas a la misma unidad exterior. Utilice el mismo circuito para las fuentes de

alimentación de las unidades interiores del mismo sistema. Se deben encender y apagar al mismo tiempo.

Interruptor

Fusible

(Opcional)

Alimentación

de la unidad

exterior

Interruptor Fusible Fusible Fusible Fusible

Alimentación de la unidad exterior

Unidad interior Unidad interior Unidad interior Unidad interior

Unidad exterior

Alimentación del control central

(Opcional)

!"#$

PRECAUCIONES

% !&'"""

% ()"#"'*+#",#-.

% /"""##"#&1"##""2"+

% ","#"*##"#&1

% ","""#"*#+"""""""

La fuente de alimentación, los protectores eléctricos de fuga y los interruptores manuales de las unidades interiores

sistema.

Para reducir la interferencia, utilice como cable de comunicación un cable apantallado de tres hilos. No utilice un

cable de multi-hilos.

El cableado lo debe hacer un ingeniero eléctrico.

12

Unidad

exterior

opcionales, contacte el distribuidor local para adquirirlas

si es necesario.

!"#$

Unidad

interior Unidad

interior Unidad

interior

Unidad

interior

4

#

"

Cableado de la unidad interior y del control de la unidad exterior

PRECAUCIONES

'""&

(5)2

"

de bus

Fig. 5-2

5.1. Cableado de la Unidad exterior

Bornero de la unidad exterior Terminales

Alimentación

Fig. 5-3

PRECAUCIONES

%

Nacional de Cableado.

%

descontinuadas, los usuarios pueden seleccionar esta función

cuando sea necesario.

Cable de comunicación entre la unidad exterior / interior

Reservado Al controlador

centralizado

Al medidor

de kilovatios-

hora

20 - 28kW

33.5kW

K1 K22 2 2 2 XX X Y P Q Q

Monitor de unid.

exterior

Controlador de

unid. interior

central

Amperíme-

tro digital

A la comunicación

de las unidades

interiores bus

Comunicación de

la unidad interior y

exterior

50

380-415

342

456

21

24.3

25

/

18.4

20.5

24.3

25

/

15

19

24.3

25

/

12.4

19

24.3

25

/

12

2×0.17

2.1+2.1

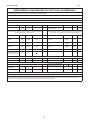

Modelo Capacidad (kW)

Hz

Voltaje

Min.(V)

Max.(V)

MSC

RLA

kW

FLA

380-415V 3N~ 50Hz

Fuente

de

alimenta

ción

Compresor

OFM

Fuente de alimentación

262220 28

Amperios máx. del fusible

Amperios del circuito mín.

Amperios totales de sobrecorriente

33.5

26.4

33.2

32

/

19.6

Tabla 5-1

% Cuando el cable de alimentación esté paralelo al cable de comunicación, inserte los cables eléctricos en sus

%

%

cableado es opcional. Para adquirir un control cableado, póngase en contacto con su distribuidor local.

13

Conexión de cables

Selle la conexión de cables con material aislante o se

NOTA

Los aires acondicionados se pueden conectar a un control central

(CCM). Antes del funcionamiento, conecte los cables correctamente

5.2. Cableado de la Unidad Interior

% Alimentación

Unidad

interior

DC

"&"

#

7

Disyuntor (A)

Cable de señal unidad

2)

(señal eléctrica débil)

Alimentación

Tabla 5-2

ẇ

3x2.5

Unidad interior

Control

centralizado Comunicación

uds. interiores

Pantalla

Control

cableado

Fig. 5-4

-

do de puesta a tierra ahora es conectar a tierra el extremo más

cercano del cable apantallado y abrir en el extremo (aislado).

El cable apantallado es para conexión a tierra.

2. El control entre la unidad exterior y la unidad interior es de tipo

BUS. Las direcciones se establecen durante la instalación.

PRECAUCIONES

tubo de distribución de cables.

NOTA

Cableado de alimentación de la unidad interior

Interruptor magnetotérmico

Interruptor manual

Unidad interior

PRECAUCIONES

Fig. 5-5

% Use un cable apantallado de 3 hilos como cable de señal

entre las unidades exterior e interior.

Cable de comunicación de la unidad exterior / interior

Unidad exterior

Extremo del cable apantallado de conexión

Cable de

comunicación

e interiores

(abierto)

comprar el controlador de cable cuando sea necesario.

PRECAUCIONES

producir un error de comunicación cuando el cableado de comunicación

excede estas limitaciones.

BLANCO

AZUL

NEGRO

AMARILLO

GRIS

NEGRO

Para cablear el controlador La

función de control de cable

reservado se indica en la tabla

de líneas discontinuas, los

usuarios pueden comprar el

controlador de cable cuando

sea necesario.

de la unidad interior-unidad interior y el cable de conexión de la unidad

interior-unidad exterior deben estar en el mismo sistema.

2.. Cuando el cable de alimentación es paralelo al cable de comunicación,

14

6. PRUEBA DE FUNCIONAMIENTO

eléctrica de control.

PRECAUCIONES

% La prueba de funcionamiento no se puede realizar hasta que

% La prueba de funcionamiento no puede comenzar hasta que

% Nunca fuerce el recorrido. (O el protector se asienta hacia

atrás y es peligroso.)

7. CONFIGURACIÓN

7.1. Resumen

Información

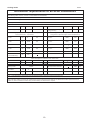

7.2. Ajustes de los micro-interruptores

ẇ

ẇ

ẇ

3

ẇ

ẇ

ẇ

ẇ

La cantidad de unidades interiores está en el

Cuando se conectan las uds. int. DC2 (por defecto)

Cuando se conecta a uds. interiores antiguas

Direccionamiento automático (por defecto)

Borrar la dirección de las unidades interiores

Prioridad automática (por defecto)

Prioridad de refrigeración

Prioridad de primera en marcha

Solo calefacción

Otras combinaciones, prioridad de calefacción

Solo prueba de fábrica

NOTA

micro-interruptores

Tabla 7-1 Solo para

unidades de

200 a 280

Prioridad automática (predeterminado)

S2

S9-1

000

100

010

110

Prioridad de enfriamiento

Primera prioridad ON

Solo calefacción

Otras combinaciones, prioridad de calefacción

Solo enfriamiento

001

Reservado

Reservado

Borrar direcciones de unidades interiores

S1-2

S1-3

0

1

0

1

Capacidad de la unidad exterior, 12HP

0

1

Direccionamiento automático (predeterminado)

1 2 3

1 2 3

S9-2

Solo prueba de fábrica

Reservado

Reservado

0

1

1 2 3

1 2 3

1 2 3

Cuando se conecta a la unidad interior de DC de 2a generación

(predeterminado)

S1-1

0

1

1 2 3

1 2 3

ENC1

&

S9-3 0-F

El número de unidades interiores está en el rango

0-15 0-9 en ENC1 indica 0-9 unidades interiores;

A-F en ENC1 indican 10-15 unidades interiores

0-7

Configuración de la dirección de red de la unidad

exterior, solo se debe seleccionar de 0 a 7 (el

valor predeterminado es 0).

El número de unidades interiores está en el rango

16-31 0-9 en ENC1 indica 16-25 unidades

interiores;

A-F en ENC1 indican 26-31 unidades interiores

ENC3

1

1 2 3

0-F

0

Tabla7-2

Solo para la unidad 335, la

unidad 335 adopta PCB diferente

Cuando se conecta a una unidad interior de AC o DC de primera generación

8. PRECAUCIONES PARA EVITAR

FUGAS DE REFRIGERANTE

ser grande para que cualquier fuga de refrigerante no pueda

alcanzar el grosor máximo. De manera que se puedan tomar

acciones importantes a tiempo.

%

% 3

Compruebe el grosor en los siguientes pasos y tome las

acciones necesarias.

+ cargas adicionales

3.. Calcule el espesor del refrigerante

-

Unidad exterior

Unidad

interior

Fuga de refrigerante en la habitación

(todo el refrigerante circula hacia arriba)

Ud. interior

A. Ventilación

lugares donde sea fácil mantener el refrigerante)

15

A[kg]

B[m ]

3

Contramedida contra sobre espesores altos

16

8.1. Información importante para el

refrigerante usado

9

2 o más, unidades de menos de

2

un sistema de detección de fugas al menos cada 24 meses

2)

3)

)

2 o más, unidades de menos de

2

)

2 o más, comprobar al menos

cada 3 meses, o cuando se instale un sistema de detección de fugas al

5)) Solo puede realizar la instalación, la manipulación y el mantenimiento un

9. CODIGOS DE ERROR

Error

Código

Error de comunicación entre la placa principal y la placa

de accionamiento del compresor

Error del sensor alta presión

Error de secuencia de la fase

Error de comunicación entre las unidades interior y exterior

Error del sensor de temperatura T3 o T4

Tensión de alimentación anormal

Error del sensor de temp. de descarga

Fallo del sensor TL

Protección de alta presión

Protección de corriente del compresor

Protección de temperatura de descarga

Protección de alta temperatura del condensador

Protección contra tormentas

Error MEC

Protección de secuencia de fase

Protección por frecuencia actual del compresor es diferente

Error de tensión del bus de DC

Irrecuperable

Irrecuperable

Irrecuperable

Irrecuperable

10.0. ENTREGA DEL MANUAL AL USUARIO

Los manuales de uso de las unidades interiores y exteriores se deben entregar al usuario. Explique en detalles el contenido

del manual de usuario a los clientes.

Atención:

Frecuencia de comprobaciones de fugas de refrigerante

Modelo

Refrigerante / kg

toneladas de CO2 equivalente

6.5 13.57

20-28kW

Carga de fábrica

33.5kW

816.71

17

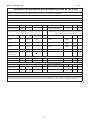

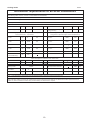

Tabla.1

UnidadValorSímbolo

metI

UnidadValorSímbolo

metI

Capacidad de

enfriamiento nominal Prated,c

Eficiencia energética estacional

de refrigeración de espacios

ηs,c

Tj=+35℃Pdc Tj=+35℃EERd

EERd

EERd

EERd

Tj=+30℃Pdc Tj=+30℃

Tj=+25℃Pdc Tj=+25℃

Tj=+20℃Pdc Tj=+20℃

Coeficiente de

degradación para aires

acondicionados(*)

Cdc

Modo off POFF PCK

Modo de apagado térmico

PTO 0 PSB

Control de capacidad

Para aire acondicionado aire-aire:

caudal de aire, medido en exteriores

m3/h

Nivel de potencia

acústica, exterior LWA

GWP del refrigerante kg CO2 eq(100años)

Detalles de contacto

Requisitos de información para acondicionadores de aire a aire

Modo de enfriamiento:

Intercambiador de calor lateral exterior del aire acondicionado: aire

Intercambiador de calor lateral interior del aire acondicionado: aire

Cuando la información se relaciona con acondicionadores de aire multi-split, el resultado de la prueba y los datos de rendimiento pueden obtenerse

sobre la base del rendimiento de la unidad exterior, con una combinación de unidades interiores recomendadas por el fabricante o importador.

Capacidad de refrigeración declarada para carga parcial a

temperaturas exteriores determinadas Tj e interior 27/19℃(bulbo

seco / húmedo)

Relación de eficiencia energética declarada o eficiencia de

utilización de gas / factor de energía auxiliar para carga parcial a

temperaturas exteriores determinadas Tj

Consumo de energía en modos distintos del "modo activo"

(*)If Cdc no se determina mediante medición, el coeficiente de degradación predeterminado de las bombas de calor será de 0,25

Tipo: accionado por compresor

Si aplica: controlador del compresor: motor eléctrico

Otros items

variable

0.25

kW

kW

kW

kW

kW

kW

kW

kW

kW

Modo calentador del cárter

Modo de espera

dB

--

--

--

--

%

20 281.4

20 3.79

14.811 4.71

9.760 9.11

6.378 12.76

0.04 0

0.04

9000

78

Modelo(s):HTW-V200WV2RN1V10

Prueba que coincida con la forma de las unidades interiores, sin conducto: 2×HTW-MI45Q4+2×HTW-MI56Q4;

2088

18

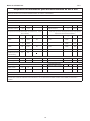

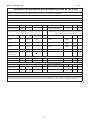

Tabla.2

Item Símbolo Valor Unidad Item Símbolo Valor Unidad

Capacidad de

calefacción nominal Prated,h kW

Eficiencia energética estacional

de calefacción de espacios

ηs,h %

Tj=-7 Pdh kW Tj=-7

Tj=+2 Pdh kW Tj=+2

Tj=+7 Pdh kW Tj=+7

Tj=+12 Pdh kW Tj=+12 --

--

--

--

--

--

Tbiv=Temperatura

bivalente Pdh kW Tbiv =Temperatura bivalente

TOL=temperatura de

operación Pdh kW TOL =temperatura de

operación

Temperatura bivalente Tbiv

Coeficiente de

degradación para

bombas de calor (**)

Cdh 0.25

Modo off POFF kW

Capacidad de calefacción de respaldo

elbu 0 kW

Modo de apagado térmico

PTO kW Tipo de entrada de energía

Modo calentador del cárter

PCK kW Modo de espera PSB kW

Control de capacidad

Para bomba de calor aire-aire: caudal

de aire, medido en exteriores

m3/h

Nivel de potencia

acústica, exterior LWA dB

GWP del refrigerante kg CO2 eq(100años)

Detalles de contacto

Requisitos de información para bombas de calor

Intercambiador de calor lateral exterior del aire acondicionado: aire

Intercambiador de calor lateral interior del aire acondicionado: aire

Otros items

(**)If Cdh no se determina mediante medición, el coeficiente de degradación predeterminado de las bombas de calor será de 0,25

Cuando la información se relaciona con bombas de calor multi-split, el resultado de la prueba y los datos de rendimiento se pueden obtener sobre

la base del rendimiento de la unidad exterior, con una combinación de unidades interiores recomendadas por el fabricante o importador.

(*)

variable

Los parámetros se declararán para la temporada de calefacción media, los parámetros para las estaciones de calefacción más cálidas y más frías son opcionales.

Indicación si el calefactor está equipado con un calefactor suplementario: no

Si aplica: controlador del compresor: motor eléctrico

Consumo de energía en modos distintos del "modo activo" Calefactor suplementario

Capacidad de calefaccióón declarada para carga parcial a

temperatura interior de 20 ℃ y temperaturas exteriores Tj

Coeficiente de rendimiento declarado o eficiencia de

utilización de gas / factor de energía auxiliar para carga

parcial a temperaturas exteriores determinadas Tj

COPd

COPd

COPd

COPd

COPd

COPd

Modo de calefacción:

20 155

10.629 3.19

6.471 3.39

6.625.763

3.652 7.57

10.629 3.19

12.310 2.44

-7

0.04

0.04

0 0.04

9000

78

2088

Modelo(s):HTW-V200WV2RN1V10

Prueba que coincida con la forma de las unidades interiores, sin conducto: 2×HTW-MI45Q4+2×HTW-MI56Q4;

19

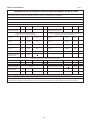

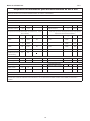

Tabla.3

UnidadValorSímbolo

metI

UnidadValorSímbolo

metI

Capacidad de

enfriamiento nominal Prated,c

Eficiencia energética estacional de

refrigeración de espacios

ηs,c

Tj=+35℃Pdc Tj=+35℃EERd

EERd

EERd

EERd

Tj=+30℃Pdc Tj=+30℃

Tj=+25℃Pdc Tj=+25℃

Tj=+20℃Pdc Tj=+20℃

Coeficiente de

degradación para aires

acondicionados(*)

Cdc

Modo off POFF PCK

Modo de apagado térmico

PTO 0 PSB

Control de capacidad

Para aire acondicionado aire-aire:

caudal de aire, medido en exteriores

m3/h

Nivel de potencia

acústica, exterior LWA

GWP del refrigerante kg CO2 eq(100años)

Detalles de contacto

Requisitos de información para acondicionadores de aire a aire

Modo de enfriamiento:

Intercambiador de calor lateral exterior del aire acondicionado: aire

Intercambiador de calor lateral interior del aire acondicionado: aire

Cuando la información se relaciona con acondicionadores de aire multi-split, el resultado de la prueba y los datos de rendimiento pueden

obtenerse sobre la base del rendimiento de la unidad exterior, con una combinación de unidades interiores recomendadas por el fabricante o

importador.

Capacidad de refrigeración declarada para carga parcial a

temperaturas exteriores determinadas Tj e interior 27/19℃(bulbo

seco / húmedo)

Relación de eficiencia energética declarada o eficiencia de

utilización de gas / factor de energía auxiliar para carga parcial a

temperaturas exteriores determinadas Tj

Consumo de energía en modos distintos del "modo activo""

(*)If Cdc no se determina mediante medición, el coeficiente de degradación predeterminado de las bombas de calor será de 0,25

Tipo: accionado por compresor

Si aplica: controlador del compresor: motor eléctrico

Otros items

variable

0.25

kW

kW

kW

kW

kW

kW

kW

kW

kW

Modo calentador del cárter

Modo de espera

dB

--

--

--

--

%

22.4 270.2

22.4 3.31

16.645 4.57

10.990 8.61

6.399 12.8

0.04

0.04

0

9000

78

Modelo(s):HTW-V224WV2RN1V10;

Prueba que coincida con la forma de las unidades interiores, sin conducto: 4×HTW-MI56Q4;

2088

20

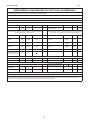

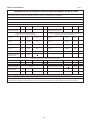

Tabla.4

Item Símbolo Valor Unidad Item Símbolo Valor Unidad

Capacidad de

calefacción nominal Prated,h kW

Eficiencia energética estacional

de calefacción de espacios

ηs,h %

Tj=-7 Pdh kW Tj=-7

Tj=+2 Pdh kW Tj=+2

Tj=+7 Pdh kW Tj=+7

Tj=+12 Pdh kW Tj=+12 --

--

--

--

--

--

Tbiv=Temperatura

bivalente Pdh kW Tbiv =Temperatura bivalente

TOL=temperatura de

operación Pdh kW

TOL =temperatura de operación

Temperatura bivalente Tbiv

Coeficiente de

degradación para

bombas de calor (**)

Cdh 0.25

Modo off POFF kW

Capacidad de calefacción de respaldo

elbu 0 kW

Modo de apagado térmico

PTO kW Tipo de entrada de energía

Modo calentador del cárter

PCK kW Modo de espera PSB kW

Control de capacidad

Para bomba de calor aire-aire: caudal

de aire, medido en exteriores

m3/h

Sound power

level,outdoor

LWA dB

GWP del refrigerante kg CO2 eq(100años)

Detalles de contacto

Requisitos de información para bombas de calor

Intercambiador de calor lateral exterior del aire acondicionado: aire

Intercambiador de calor lateral interior del aire acondicionado: aire

Otros items

(**)If Cdh no se determina mediante medición, el coeficiente de degradación predeterminado de las bombas de calor será de 0,25

Cuando la información se relaciona con bombas de calor multi-split, el resultado de la prueba y los datos de rendimiento se pueden obtener sobre

la base del rendimiento de la unidad exterior, con una combinación de unidades interiores recomendadas por el fabricante o importador.

(*)

variable

Los parámetros se declararán para la temporada de calefacción media, los parámetros para las estaciones de calefacción más cálidas y más frías son opcionales.

Indicación si el calefactor está equipado con un calefactor suplementario: no

Si aplica: controlador del compresor: motor eléctrico

Consumo de energía en modos distintos del "modo activo" Calefactor suplementario

Capacidad de calefacción declarada para carga parcial a

temperatura interior de 20 ℃ y temperaturas exteriores Tj

Coeficiente de rendimiento declarado o eficiencia de

utilización de gas / factor de energía auxiliar para carga

parcial a temperaturas exteriores determinadas Tj

COPd

COPd

COPd

COPd

COPd

COPd

Modo de calefacción:

22.4 167.4

12.113 3.22

7.272 3.56

5.825 6.76

3.703 7.76

12.113 3.22

13.74 2.35

-7

0.04

0.04

0 0.04

9000

78

2088

Modelo(s):HTW-V224WV2RN1V10;

Prueba que coincida con la forma de las unidades interiores, sin conducto: 4×HTW-MI56Q4;

21

Tabla.5

UnidadValorSímbolo

metI

UnidadValorSímbolo

metI

Capacidad de

enfriamiento nominal Prated,c

Eficiencia energética estacional

de refrigeración de espacios

ηs,c

Tj=+35℃Pdc Tj=+35℃EERd

EERd

EERd

EERd

Tj=+30℃Pdc Tj=+30℃

Tj=+25℃Pdc Tj=+25℃

Tj=+20℃Pdc Tj=+20℃

Coeficiente de

degradación para aires

acondicionados(*)

Cdc

Modo off POFF PCK

Modo de apagado térmico

PTO 0 PSB

Control de capacidad

Para aire acondicionado aire-aire:

caudal de aire, medido en exteriores

m3/h

Nivel de potencia

acústica, exterior LWA

GWP del refrigerante kg CO2 eq(100años)

Detalles de contacto

Requisitos de información para acondicionadores de aire a aire

Modo de enfriamiento:

Intercambiador de calor lateral exterior del aire acondicionado: aire

Intercambiador de calor lateral interior del aire acondicionado: aire

Cuando la información se relaciona con acondicionadores de aire multi-split, el resultado de la prueba y los datos de rendimiento pueden obtenerse

sobre la base del rendimiento de la unidad exterior, con una combinación de unidades interiores recomendadas por el fabricante o importador.

Capacidad de refrigeración declarada para carga parcial a

temperaturas exteriores determinadas.

Tj e interior 27/19℃(bulbo seco / húmedo)

Relación de eficiencia energética declarada o eficiencia de

utilización de gas / factor de energía auxiliar para carga parcial a

temperaturas exteriores determinadas Tj

Consumo de energía en modos distintos del "modo activo"

(*)If Cdc no se determina mediante medición, el coeficiente de degradación predeterminado de las bombas de calor será de 0,25

Tipo: accionado por compresor

Si aplica: controlador del compresor: motor eléctrico

Otros items

variable

kW

kW

kW

kW

kW

kW

kW

kW

kW

Modo calentador del cárter

Modo de espera

dB

--

--

--

--

%

26 259

26 2.59

18.843 4.53

12.745 8.35

6.330

0.25

12.66

0.04 0

0.04

10000

78

Modelo(s):HTW-V260WV2RN1V10;

Prueba que coincida con la forma de las unidades interiores, sin conducto: 2×HTW-MI45Q4+2×HTW-MI90Q4;

2088

22

Tabla.6

Item Símbolo Valor Unidad Item Símbolo Valor Unidad

Capacidad de

calefacción nominal Prated,h kW

Eficiencia energética estacional de

calefacción de espacios

ηs,h %

Tj=-7 Pdh kW Tj=-7

Tj=+2 Pdh kW Tj=+2

Tj=+7 Pdh kW Tj=+7

Tj=+12 Pdh kW Tj=+12 --

--

--

--

--

--

Tbiv=Temperatura

bivalente Pdh kW Tbiv =Temperatura bivalente

TOL=temperatura de

operación Pdh kW TOL =

temperatura de operación

Temperatura bivalente Tbiv

Coeficiente de

degradación para

bombas de calor (**)

Cdh 0.25

Modo off POFF kW

Capacidad de calefacción de respaldo

elbu 0 kW

Modo de apagado térmico

PTO kW Tipo de entrada de energía

Modo calentador del cárter

PCK kW Modo de espera PSB kW

Control de capacidad

Para bomba de calor aire-aire:

caudal de aire, medido en exteriores

m3/h

Nivel de potencia

acústica, exterior LWA dB

GWP del refrigerante kg CO2 eq(100años)

Detalles de contacto

Requisitos de información para bombas de calor

Intercambiador de calor lateral exterior del aire acondicionado: aire

Intercambiador de calor lateral interior del aire acondicionado: aire

Otros items

(**)If Cdh no se determina mediante medición, el coeficiente de degradación predeterminado de las bombas de calor será de 0,25

Cuando la información se relaciona con bombas de calor multi-split, el resultado de la prueba y los datos de rendimiento se pueden obtener sobre

la base del rendimiento de la unidad exterior, con una combinación de unidades interiores recomendadas por el fabricante o importador.

(*)

variable

Los parámetros se declararán para la temporada de calefacción media, los parámetros para las estaciones de calefacción más cálidas y más frías son opcionales.

Indicación si el calefactor está equipado con un calefactor suplementario: no

Si aplica: controlador del compresor: motor eléctrico

Consumo de energía en modos distintos del "modo activo" Calefactor suplementario

Capacidad de calefacción declarada para carga parcial a

temperatura interior de 20 ℃ y temperaturas exteriores Tj

Coeficiente de rendimiento declarado o eficiencia de

utilización de gas / factor de energía auxiliar para carga

parcial a temperaturas exteriores determinadas Tj

COPd

COPd

COPd

COPd

COPd

COPd

Modo de calefacción:

26 178.2

13.663 3.17

8.703 3.90

6.027 7.17

3.881 8.36

13.633 3.17

15.861 2.32

-7

0.04

0.04

0 0.04

10000

78

2088

Modelo(s):HTW-V260WV2RN1V10;

Prueba que coincida con la forma de las unidades interiores, sin conducto: 2×HTW-MI45Q4+2×HTW-MI90Q4;

23

Tabla.7

UnidadValorSímbolo

metI

UnidadValorSímbolo

metI

Capacidad de

enfriamiento nominal Prated,c

Eficiencia energética estacional

de refrigeración de espacios

ηs,c

Tj=+35℃Pdc Tj=+35℃EERd

EERd

EERd

EERd

Tj=+30℃Pdc Tj=+30℃

Tj=+25℃Pdc Tj=+25℃

Tj=+20℃Pdc Tj=+20℃

Coeficiente de

degradación para aires

acondicionados(*)

Cdc

Modo off POFF PCK

Modo de apagado térmico

PTO PSB

Control de capacidad

Para aire acondicionado aire-aire:

caudal de aire, medido en exteriores

m3/h

Nivel de potencia

acústica, exterior LWA

GWP del refrigerante kg CO2 eq(100años)

Detalles de contacto

Requisitos de información para acondicionadores de aire a aire

Modo de enfriamiento:

Intercambiador de calor lateral exterior del aire acondicionado: aire

Intercambiador de calor lateral interior del aire acondicionado: aire

Cuando la información se relaciona con acondicionadores de aire multi-split, el resultado de la prueba y los datos de rendimiento pueden obtenerse

sobre la base del rendimiento de la unidad exterior, con una combinación de unidades interiores recomendadas por el fabricante o importador.

Capacidad de refrigeración declarada para carga parcial a

temperaturas exteriores determinadas Tj e interior 27/19℃(bulbo

seco / húmedo)

Relación de eficiencia energética declarada o eficiencia de

utilización de gas / factor de energía auxiliar para carga parcial a

temperaturas exteriores determinadas Tj

Consumo de energía en modos distintos del "modo activo"

(*)If Cdc no se determina mediante medición, el coeficiente de degradación predeterminado de las bombas de calor será de 0,25

Tipo: accionado por compresor

Si aplica: controlador del compresor: motor eléctrico

Otros items

variable

kW

kW

kW

kW

kW

kW

kW

kW

kW

Modo calentador del cárter

Modo de espera

dB

--

--

--

--

%

28 251

28 2.33

20.662 4.31

13.537 8.16

6.328 12.66

0.04 0.04

0 0.04

11000

78

2088

Modelo(s):HTW-V280WV2RN1V10;

Prueba que coincida con la forma de las unidades interiores, sin conducto: 2×HTW-MI56Q4+2×HTW-MI90Q4;

0.25

24

Tabla.8

Item Símbolo Valor Unidad Item Símbolo Valor Unidad

Capacidad de

calefacción nominal Prated,h kW

Eficiencia energética estacional

de calefacción de espacios

ηs,h %

Tj=-7 Pdh kW Tj=-7

Tj=+2 Pdh kW Tj=+2

Tj=+7 Pdh kW Tj=+7

Tj=+12 Pdh kW Tj=+12 --

--

--

--

--

--

Tbiv=Temperatura

bivalente Pdh kW Tbiv =Temperatura bivalente

TOL=temperatura de

operación Pdh kW TOL =temperatura de

operación

Temperatura bivalente Tbiv

Coeficiente de

degradación para

bombas de calor (**)

Cdh

Modo off POFF kW

Capacidad de calefacción de respaldo

elbu kW

Modo de apagado térmico

PTO kW Tipo de entrada de energía

Modo calentador del cárter

PCK kW Modo de espera PSB kW

Control de capacidad

Para bomba de calor aire-aire:

caudal de aire, medido en exteriores

m3/h

Nivel de potencia

acústica, exterior LWA dB

GWP del refrigerante kg CO2 eq(100años)

Detalles de contacto

Requisitos de información para bombas de calor

Intercambiador de calor lateral exterior del aire acondicionado: aire

Intercambiador de calor lateral interior del aire acondicionado: aire

Otros items

(**)If Cdh no se determina mediante medición, el coeficiente de degradación predeterminado de las bombas de calor será de 0,25

Cuando la información se relaciona con bombas de calor multi-split, el resultado de la prueba y los datos de rendimiento se pueden obtener sobre

la base del rendimiento de la unidad exterior, con una combinación de unidades interiores recomendadas por el fabricante o importador.

(*)

variable

Los parámetros se declararán para la temporada de calefacción media, los parámetros para las estaciones de calefacción más cálidas y más frías son opcionales.

Indicación si el calefactor está equipado con un calefactor suplementario: no

Si aplica: controlador del compresor: motor eléctrico

Consumo de energía en modos distintos del "modo activo" Calefactor suplementario

Capacidad de calefacción declarada para carga parcial a

temperatura interior de 20 ℃ y temperaturas exteriores Tj

Coeficiente de rendimiento declarado o eficiencia de

utilización de gas / factor de energía auxiliar para carga

parcial a temperaturas exteriores determinadas Tj

COPd

COPd

COPd

COPd

COPd

COPd

Modo de calefacción:

28 179.4

15.715 2.93

9.445 3.99

6.060 7.26

3.906 8.48

15.715 2.93

17.534 2.21

-7

0.25

0.04

0.04

00.04

0

11000

78

2088

Modelo(s):HTW-V280WV2RN1V10;

Prueba que coincida con la forma de las unidades interiores, sin conducto: 2×HTW-MI56Q4+2×HTW-MI90Q4;

25

Tabla.9

UnidadValorSímbolo

metI

UnidadValorSímbolo

metI

Capacidad de

enfriamiento nominal Prated,c

Eficiencia energética estacional

de refrigeración de espacios

ηs,c

Tj=+35℃Pdc Tj=+35℃EERd

EERd

EERd

EERd

Tj=+30℃Pdc Tj=+30℃

Tj=+25℃Pdc Tj=+25℃

Tj=+20℃Pdc Tj=+20℃

Coeficiente de

degradación para aires

acondicionados(*)

Cdc

Modo off POFF PCK

Modo de apagado térmico

PTO PSB

Control de capacidad

Para aire acondicionado aire-aire:

caudal de aire, medido en exteriores

m3/h

Nivel de potencia

acústica, exterior LWA

GWP del refrigerante kg CO2 eq(100años)

Detalles de contacto

Requisitos de información para acondicionadores de aire a aire

Modo de enfriamiento:

Intercambiador de calor lateral exterior del aire acondicionado: aire

Intercambiador de calor lateral interior del aire acondicionado: aire

Cuando la información se relaciona con acondicionadores de aire multi-split, el resultado de la prueba y los datos de rendimiento pueden

obtenerse sobre la base del rendimiento de la unidad exterior, con una combinación de unidades interiores recomendadas por el fabricante o

importador.

Capacidad de refrigeración declarada para carga parcial a

temperaturas exteriores determinadas Tj e interior 27/19℃(bulbo

seco / húmedo)

Relación de eficiencia energética declarada o eficiencia de

utilización de gas / factor de energía auxiliar para carga parcial a

temperaturas exteriores determinadas Tj

Consumo de energía en modos distintos del "modo activo"

(*)If Cdc no se determina mediante medición, el coeficiente de degradación predeterminado de las bombas de calor será de 0,25

Tipo: accionado por compresor

Si aplica: controlador del compresor: motor eléctrico

Otros items

variable

kW

kW

kW

kW

kW

kW

kW

kW

kW

Modo calentador del cárter

Modo de espera

dB

%

--

--

--

--

33.5 253.8

33.500 2.19

23.814 4.21

15.216 8.36

7.644 15.29

0.03 0

0 0.03

11300

81

2088

Modelo(s):HTW-V335WV2RN1V10;

Test matching indoor units form, non-duct : 6 ×HTW-MI56Q4;

0.25

26

Tabla.10

Item Símbolo Valor Unidad Item Símbolo Valor Unidad

Capacidad de

calefacción nominal Prated,h kW

Eficiencia energética estacional

de calefacción de espacios

ηs,h %

--

--

--

--

--

--

Tj=-7 Pdh kW Tj=-7

Tj=+2 Pdh kW Tj=+2

Tj=+7 Pdh kW Tj=+7

Tj=+12 Pdh kW Tj=+12

Tbiv=Temperatura

bivalente Pdh kW Tbiv =Temperatura bivalente

TOL=temperatura de

operación Pdh kW TOL =t

emperatura de operación

Temperatura bivalente Tbiv

Coeficiente de

degradación para

bombas de calor (**)

Cdh

Modo off POFF kW

Capacidad de calefacción de respaldo

elbu kW

Modo de apagado térmico

PTO kW Tipo de entrada de energía

Modo calentador del cárter

PCK kW Modo de espera PSB kW

Control de capacidad

Para bomba de calor aire-aire:

caudal de aire, medido en exteriores

m3/h

Nivel de potencia

acústica, exterior LWA dB

GWP del refrigerante kg CO2 eq(100años)

Detalles de contacto

Requisitos de información para bombas de calor

Intercambiador de calor lateral exterior del aire acondicionado: aire

Intercambiador de calor lateral interior del aire acondicionado: aire

Otros items

(**)If Cdh no se determina mediante medición, el coeficiente de degradación predeterminado de las bombas de calor será de 0,25

Cuando la información se relaciona con bombas de calor multi-split, el resultado de la prueba y los datos de rendimiento se pueden obtener sobre

la base del rendimiento de la unidad exterior, con una combinación de unidades interiores recomendadas por el fabricante o importador.

(*)

variable

Los parámetros se declararán para la temporada de calefacción media, los parámetros para las estaciones de calefacción más cálidas y más frías son opcionales.

Indicación si el calefactor está equipado con un calefactor suplementario: no

Si aplica: controlador del compresor: motor eléctrico

Consumo de energía en modos distintos del "modo activo" Calefactor suplementario

Capacidad de calefacción declarada para carga parcial a

temperatura interior de 20 ℃ y temperaturas exteriores Tj

Coeficiente de rendimiento declarado o eficiencia de

utilización de gas / factor de energía auxiliar para carga

parcial a temperaturas exteriores determinadas Tj

COPd

COPd

COPd

COPd

COPd

COPd

Modo de calefacción:

33.5 155.4

17.114 2.3

10.512 3.54

6.894 7.00

3.214 5.48

17.114 230

19.50 2.25

-7

0.25

0.03

0.03

00.03

0.03

11300

81

2088

Modelo(s):HTW-V335WV2RN1V10;

Prueba que coincida con la forma de las unidades interiores, sin conducto: 6×HTW-MI56Q4;

ENGLISH

Installation Manual

MINI VRF V10

OUTDOOR UNIT

HTW-V200WV2RN1V10 | HTW-V224WV2RN1V10

HTW-V260WV2RN1V10 | HTW-V280WV2RN1V10

HTW-V335WV2RN1V10

1

1. PRECAUTIONS

CAUTION

CONTENTS PAGE

PRECAUTIONS........................................................................................1

ATTACHED FITTINGS..............................................................................2

OUTDOOR UNIT INSTALLATION..............................................................3

INSTALL THE CONNECTING PIPE............................................................4

ELECTRICAL WIRING..............................................................................9

TEST RUNNING.

..

......

..

..................

..

...........

...............................

.......

..

.

..

12

CONFIGURATION.......

..

..................

..

...........

...............................

.......

..

.

..

12

PRECAUTIONS ON REFRIGERANT LEAKAGE.........................................13

ERROR CODES......................................................................................14

TURN OVER TO CUSTOMER..................................................................14

Ensure that all Local, National and International regulations

are satisfied.

Read this ”PRECAUTIONS ” carefully before Installation.

The precautions described below include the important

items regarding safety. Observe them without fail.

After the installation work, perform a trial operation to check

for any problem.

Follow the Owner’s Manual to explain how to use and

maintain the unit to the customer.

Turn off the main power supply switch (or breaker) before

maintenance the unit .

Ask the customer that the Installation Manual and the Owner’s

Manual should be kept together .

New Refrigerant Air Conditioner Installation

CAUTION

Do not connect the Appliance from Main Power Supply directly.

WARNING

THIS AIR CONDITIONER ADOPTS THE NEW HFC

REFRIGERANT(R410A)WHICH DOES NOT DESTROY OZONE

LAYER.

The characteristics of R410A refrigerant are; Hydrophilic, oxid-

izing membrane or oil, and its pressure is approx.1.6 times high-

er than that of refrigerant R22.Accompanied with the new refrig-

erant, refrigerating oil has also been changed ,Therefore, during

installation work, be sure that water, dust, former refrigerant, or

refrigerating oil does not enter the refrigerating cycle.

To prevent charging an incorrect refrigerant and refrigerating oil,

the sizes of connecting sections of charging port of the main

unit and installation tools are charged from those for the

conventional refrigerant.

Accordingly the exclusive tools are required for the new

refrigerant (R410A):

For connecting pipes, use new and clean piping designed for

R410A,and please care so that water or dust does not enter.

Moreover, do not use the existing piping because there are

problems with pressure-resistance force and impurity in it.

Ask an authorized dealer or qualified installation professional to

install/maintain the air conditioner.

Inappropriate installation may result in water leakage,electric shock

or fire.

Turn off the main power supply switch or breaker before

attempting any electrical work.

Make sure all power switches are off.Failure to do so may cause

electric shock.

Connect the connecting cable correctly.

If the connecting cable is connected in a wrong way, electric parts

may be damaged.

When moving the air conditioner for the installation into another

place, be very careful not to enter any gaseous matter other

than the specified refrigerant into the refrigeration cycle.

If air or any other has is mixed in refrigerant, the gas pressure in the

refrigeration cycle becomes abnormally high and it may resultingly

causes pipe burst and injuries on persons.

Do not modify this unit by removing any of the safety guards or

by by-passing any of the safety interlock switches.

Exposure of unit to water or other moisture before installation

may cause a short-circuit of electrical parts.

Do not store it in a wet basement or expose to rain or water.

After unpacking the unit, examine it carefully if there are

possible damage.

Do not install in a place that might increase the vibration of the

unit.

To avoid personal injury (with sharp edges), be careful when

handling parts.

Perform installation work properly according to the Installation

Manual.

Inappropriate installation may result in water leakage, electric shock

or fire.

When the air conditioner is installed in a small room, provide

appropriate measures to ensure that the concentration of

refrigerant leakage occur in the room does not exceed the

critical level.

Install the air conditioner securely in a location where the base

can sustain the weight adequately.

Perform the specified installation work to guard against an

earthquake.

If the air conditioner is not installed appropriately, accidents may

occur due to the falling unit.

If refrigerant gas has leaked during the installation work,

ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas

may generate.

After the installation work, confirm that refrigerant gas doer not

leak.

If refeigerant gas leaks into the room and flows near a fire source,

such as a cooking range, noxious gas might generate.

Electrical work must be performed by a qualified electrician in

accordance with the Installation Manual. Make sure the air

conditioner uses an exclusive power supply.

The appliance shall be installed in accordance with national wiring

regulations.

If the supply cord is damaged, it must be replaced by the

manufacture or its service agent or a similarly qualified person

in order to avoid a hazard.

An all-pole disconnection switch having a contact separation of at

least 3mm in all poles should be connected in fixed wiring.

The dimensions of the space necessary for correct installation

of the appliance including the minimum permissible distances

in order to avoid a hazard.

2

2. ATTACHED FITTINGS

Please check whether the following fittings are of full scope. If there are some spare fittings , please restore them carefully.

QUANTITY

INSTALLATION FITTINGS

SHAPENAME

1. Outdoor unit installation manual

2. Outdoor unit owner’s manual

4.Water outlet connection pipe

--

1

5.Matched resistance

6.Waterproof chassis cover

7.Connection pipe(26/28/33.5kW)

2

1

2

3. Installation Instructions:

Indoor Unit Manifold

1

1

An insufficient power supply capacity or inappropriate installation

may cause fire.

Use the specified cables for wiring connect the terminals

securely fix. To prevent external forces applied to the terminals

from affecting the terminals.

Be sure to provide grounding.

Do not connect ground wires to gas pipes, water pipes, lightning rods

or ground wires for telephone cables.

Conform to the regulations of the local electric company when

wiring the power supply.

Inappropriate grounding may cause electric shock.

Do not install the air conditioner in a location subject to a risk

of exposure to a combustible gas.

If a combustible gas leaks, and stays around the unit, a fire may occur.

6) Reamer

7) Gas leak detector

8) Tape measure

9) Thermometer

10) Mega-tester

11) Electro circuit tester

12) Hexagonal wrench

13) Flare tool

14) Pipe bender

15) Level vial

16) Metal saw

17) Gauge manifold (Charge hose:R410A special requirement)

18) Vacuum pump (Charge hose:R410A special requirement)

19) Torque wrench

1/4(17mm)16N•m (1.6kgf•m)

3/8(22mm)42N•m (4.2kgf•m)

1/2(26mm)55N•m (5.5kgf•m)

5/8(15.9mm)120N•m (12.0kgf•m)

20) Copper pipe gauge adjusting projection margin

21) Vacuum pump adapter

Required tools for installation work

1) Philips screw driver

2) Hole core drill(65mm)

3) Spanner

4) Pipe cutter

5) Knife

Refrigerant Piping

Piping kit used for the conventional refrigerant cannot be used.

Use copper pipe with 0.8 mm or more thickness for φ9.5.

Use copper pipe with 1.0 mm or more thickness for φ15.9.

Use copper pipe with 1.0 mm or more thickness for φ19.0.

Flare nut and flare works are also different form those of the

conventional refrigerant.take out the flare nut attached to the main

unit of the air conditioner, and use it.

Before installation

Be careful to the following items before installation.

Air purge

For air purge, use a vacuum pump.

Do not use refrigerant charged in the outdoor unit for air purge.

(The refrigerant for air purge is not contained in the outdoor unit.)

Electrical cabling

Be sure to fix the power cables and indoor/outdoor connecting

cables with clamps so that they do not contact with the cabinet, etc.

Installation Place

A place which provides a specified space around the outdoor unit.

A place were the operation noise and discharged air are not given

to your neighbors.

A place that is not exposed to a strong wind.

A place that does not block a passage.

When the outdoor unit is installed in an elevated position, make

sure it's four feet securely installed.

There must be sufficient space for carrying in the unit.

A place where the drain water does not make any problem.

Install the outdoor unit at a place where discharge air is not blocked.

When an outdoor unit is installed in a place that is always exposed

to a strong wind like a coast or on a high storey of a building, secure

a normal fan operation by using a duct or a wind shield.

CAUTION

The temperature of refrigerant circuit will be high, please keep the

interconnection cable away from the copper tube.

The power cord type designation is H05RN-For above/H07RN-F.

For appliances intended for use at altitudes exceeding 2000m, the

maximum altitude of use shall be stated.

3

Keep indoor unit, outdoor unit, power supply wiring and

transmission wiring at least 1 meter away from televisions

and radios. This is to prevent image interference and

noise in those electrical appliances. (Noise may be

generated depending on the conditions under which the

electric wave is generated, even if 1 meter is kept.)

3. OUTDOOR UNIT INSTALLATION

3.1 Installation place

CAUTION

There is combustible gas leakage.

There is much oil (including engine oil) ingredient.

Please keep away from the following place, or malfunction of the

machine may be caused:

There is salty air surrounding(near the coast)

There is caustic gas (the sulfide, for example) existing in the

air (near a hotspring)

A place the heat air expelled out from the outdoor unit can

reach your neighbor’s window.

A place that the noise interferes your neighbors every day

life.

A place that is too weak to bear the weight of the unit

Uneven place.

Insufficient ventilation place.

Near a private power station or high Frequency equipment.

The insulation of the metal parts of the building and the air

conditioner should comply with the regulation of National Electric

Standard.

Install indoor unit, outdoor unit, power cord and connecting

wire at least 1m away from TV set or radio to prevent noise or

picture interference.

Strong

wind

Strong

wind

3.2 Installation space (Unit:mm)

>300

>600

>300

>0003

(Wall or obstacle)

Maintain the electric

wire and pipeline

Air outlet

Air inlet

Air inlet

Fig.2-2

Fig.2-1

Fig.3-2

Fig.3-1

Single unit installation

Fig.3-3

Fig.3-4

>3000 >1000 >6000 >4000 >300

>600

>3000

>300

Parallel connect the two units or above

Parallel connect the front with rear sides

When installing the outdoor unit in a place that is constantly

exposed to a strong wind such as the upper stairs or rooftop of a

building, apply the windproof measures referring to the following

examples.

Install the unit so that its discharge port faces to the wall of the

building. Keep a distance 3000mm or more between the unit and

the wall surface.

Do not mount the outdoor unit on a wall.

Supposing the wind direction during the operation season of the

discharge port is set at right angle to the wind direction.

Installation in the following places may result in some troubles.

Do not install the unit in such places below.

A place full of machine oil.

A place full of sulphuric gas.

A place where high-frequency radio waves are likely to be

generated as from audio quipment, welders, and medical

equipment.

3000

668 206

440

400

528

494

1558

1120

4

All the pictures in this manual are for explanation purpose only.

They may be slightly different from the air conditioner you

purchased(depend on model).The actual shape shall prevail.

NOTE

3.3 Moving and installation

Since the gravity center of the unit is not at its physical center,

so please be careful when lifting it with a sling.

Never hold the inlet of the outdoor unit to prevent it from

deforming.

Do not touch the fan with hands or other objects.

Do not lean it more than 45°, and do not lay it sidelong.

Make concrete foundation according to the sepecifications of

the outdoor units.(refer to Fig.3-5)

Fasten the feet of this unit with bolts firmly to prevent it from

collapsing in case of earthquake or strong wind.

(refer to Fig.3-5)

Fig.3-6

The indoor and outdoor connecting pipe interface and power

line outlet

3.4 Centralized Chassis Drainage

Vavious piping and viring patterns can be selected,such as out from

the front ,the back the side ,and undersurface, etc.(The follow display

the locations of several piping and wiring knock-off interfaces)

To prevent the refrigerant piping from oxidizing inside when

welding, it is necessary to charge nitrogen, or oxide will chock

the circulation system.

CAUTION

4. INSTALL THE CONNECTING PIPE

Check whether the height drop between the indoor unit and

outdoor unit, the length of refrigerant pipe, and the number of

the bends meet the following requirements:

4.1 Refrigerant piping

Fig.4-1

Please pay attention to avoid the components while connect to

the connecting pipes.

While installing the outdoor unit, pay attention to the installation

place and the drainage pattern;

if it’s installed at the alpine zone, the frozen condensed water will

block up the water outlet, please pull out the rubber stopper of the

reserve water outlet. If that still fails to satisfy for the water draining,

please knock open the other two water outlets, and keep the water

can drain in time.

Pay attention to the knock the reserve water outlet from outside to

inside, and it will be beyond repair after knocking open, please pay

attention to the installation place, lest cause the inconvenience.

Please do the moth proofing for the knocked out hole, to avoid the

pest processing into and destroy the components.

CAUTION

1. Side out pipe: cut the side hole of the pipe-outlet plate selectively.

It is suggested to cut a piece of metal plate below to avoid the mouse

come and destroy the machine wiring body.

2.Front out pipe: cut the frontal hole of the pipe-outlet plate selectively.

It is suggested to cut a piece of metal plate right side to avoid the

mouse come and destroy the machine wiring body.

3. Wiring of power cord: the strong and weak electrical wire should be

out through the two plastic holes of the pipe-outlet plate, and binded

with gas and liquid pipe together.

CAUTION

Use soap water or leak detector to check every joint whether leak or

not (Refer to Fig.4-2).Note:

A is low pressure side stop valve

B is high pressure side stop valve

C and D is connecting pipes interface of indoor and outdoor units

4.2 Leak Detection

Fig.3-5

>600

Fix with bolt

When the outdoor unit requires centralized drainage, install the

chassis and two waterproof covers for the chassis, as shown in

Figure 3-6. Install the water outlet union pipe and sealing ring on

the chassis, and then connect the drainage pipe to complete

centralized drainage installation.

Sealing ring for the

water outlet union pipe

Waterproof chassis cover

Table 4-1

Front out pipe Side out pipe

5

NOTE

Size of main pipe and corresponding branch joint and branch

header