Westerbeke 7.0 BCDT - 50 Hz Guía del usuario

- Tipo

- Guía del usuario

"'

q

'

D~

.·

BCGT

GENERATORS

A C

ELECTRICAL

TESTING

.

and

TROUBL

liNG

GUIDE

t~

'WESTERBEKE

~

WESTERBEKE CORPORATION • MYLES STANDISH INDUSTRIAL PARK

150

JOHN

HANCOCK ROAD • TAUNTON MA 02780-7319 •

TEL.

1-508-823-7677

FAX 1-508-884-9688 • WEBSITE; WWW.WESTERBEKE.COM

----

§.JijJ(J Member National Marine Manufacturers Association

2nd

Revision

October

2016

TABLE

Of

CONTENTS

Introduction

•..•..•.••............••••...••••••••.•.

~

••

1 :

Testing

the

Capacitors

•.....•....•.••••••.........••. 4

Preliminary

Checking

.............•...•....•.•....•• 1

12

Volt

Excitation

....••..•......•..•.••••.........••. 4

Troubleshooting

Chart

••.•...•...••......•.•.•.....•. 1

Testing

the

Charging

Circuit.

....................... 4.

Testing

Generator

Components

••••.......••....••• 2

Testing

the

Bridge

Rectifier

........................ 5

Testing

Rotor

Windings

............................. 2

~ntegral

Controller

................................... 5

Testing

Diodes

..••...•.•..•...•.••.••......••••......• 2

Testing

the

Integral

Controller

•.. , .••..•......••... 5

Testing

the

Suppressor

.............................. 2

Fuse

Protection

•..•.•••••••.••.••••

~

•••••••...•.•..••. 5 ·

Testing

Exciter

Windings

•.•••.•.•..••....•••...•.... 3 ·

Testing

the

Main

Stator

Windings

••••••...•...•••. 6

Measuring

Resistance

•••••.•••.•••....•.••...••.•.• 3 ·

Residual

Voltage

Check

••.•.•••.•.•••••••...•...•.•. 6

Checking

Continuity

.................................. 3

Internal

Wiring

Diagrams

........................... 7

Discharging

the

Capacitors

••..•••.•..••.••••••••••• 3

AC

Connections

•••.•••••.•..•.•.••..••••••..•.....•..• 7 ·

I~IWESTERBEKE

) Engines & Generators

BCGT

GENERATOR

ELECTRICAl

TESTING

INTRODUCnOR

·

The

following

test

procedures

can

be

used to troubleshoot

WES1ER.BEKES

2

POLE

SINGLE

CAPACJTOR

BRUSHLESS

GENERATORS.

Oue

to

the simplicity

of

th~

generator,

troubleshooting

is relatively easy. ·

Field

testing

and

repairing

can

be

accomplished with basic

tools

and repair

parts

which should include the following:

A

qualitY

multimeter[multitester] capable

of

reading

less

than

one

Ohm

and

with a specific diode testing

function.

·

Basic electrical tools including cutters. soldering

iron~

wire stripper/crimper, terminals connectors,

etc.

·

.

.Repair~

such

·as

diodes suppressors,

fuses.,

bridge

rectifier,

etc.

PREliMitWlY

CIIECKIIG

B~ore

electrical

testing

checJ:c

for preper

ellc.oine

speed/hertz

adjustment.

Low

engine

speed

will cause low

AC

voltage

output. high engine speed-bighAC output.

·Refer

to

WESTERBEKES

operators manual or service

manual

for

engine

speed/benz

adjustment

or for other ·

possible.

engine

related

problems.

Before

testing.

get a clear explanation of the problem that

exists,

be

certain it relates

to_

generator components.

A

YIAIUitm:

AC

;md

DC

cin:llifS

lllfen

share

fire

same

disflilnltln'

panel~

Be

t:etfain

fD

lfiiPillg

At:

/IDWllT

allis

tllld

sbllldiJwn

DI:JAC

ilwerleiS

..

Simply

swiiciDg

Dlf

t:irt:llit

lnaltels lfillllllt

d11

the

job

siDt:e

it

will stiH

leae bllt.wires

Dll

tbe

SII/IJIIyside

Ill the

panel.

A

WARmNG:

Slime

Ill

the

f11HIIIllling

tests

teflllite tire

,.,.atDr fll be

lfiDIJill~

make

certain

the fnmt

puiley

t:IIJel•d

fillling belt

CIJliiDS

are

ill

place.

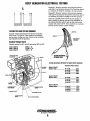

This

chart

is

compiled

with

the

engine

operating

at

the

correct

speed.

· .

Letters

A,B,C,D,

refer

to

the

diagram

below.

GENERATOR

TROUBLESHOOTING

CHART

FAULT

No

_AC

Output

Residual

Voltage

7-8

VAC

(Hot-N)

Low

AC

Output

(60-100

VAC)

High

AC

Output

Voltage

Drop

under

Motor

Load

No

Battery

Charge

Low

Battery

Charge

Unstable

Voltage

(Refer

to

Operators

Manual)

CAUSE

.

·Shorter

StatoP

Open

Stator

Shorted

Suppressors

Shorted

Diodes

Shorted

Exciter

Open

Exciter

Faulty

Rotor

Faulty

Diode

Faulty

Capacitor

Faulty

Suppressor

Incorrect

Voltage

tap

on

capacitor

Incorrect

MFD

rated

capacitor

Incorrect

Hertz

tap

on

capacitor

·

Faulty

Rotor

Diode

Faulty

Bridge

Rectifier

Faulty

Integral

Controller

Check

Fuse

Faulty

Winding

Check

Engine

S11eed

(hertz)

Adjust

Governor

Check

Capacitor

Connections

and

AC

Terminal

Wiring

(Refer

to

Wiring

Diagram)

TEST

c·

c

A

A

0

0

A

A

CAP

A

c

c

c

A

B

B

B

B

Noisy

Operation

Check

Coupling,

Check

Bearing

TWO

POLE

BC

GENERATOR

INTERNAL

WIRING

r--------.,

!AfHi

: :

~~--~

1·

I

r

I

I.

I

I

I

I

I

l

I

I·

l

I

l

c:

C

4

.

~

Drrrn

C'fS'I

ooo~J..,

L·

letters

reference-the

troubleshooting

chart

above

capacitor

~

WESTERBEKE

Engines & Generators

1

A

·ROTOR

WlijOINGS

B ·

BATfERY

CHARGE

WINDING

C

·sTATOR

WINDINGS

D

·CAPACITOR

WINDING

BCGT

GENERATOR

ElECTRICAL

TESTING

TESTING

GENERATOR

COMPONENTS

TESTING

RDmB

WINDINGS

Assume that the diodes

are

OK.

Test

the

resistance values

of

the

rotor windings

by

placing

the

multitester leads

across the diode

as

shown

and

compare to

the

data below.

Modei4.5Kw

8'"-C

----

Modei7.2Kw

BC"---'----

Model9.6Kw

BC.--'----

If

the data

is.cOIJeCt,

the problem

in

NOT

in

the rotor.

To

continue

testing,

remove fue diode/suppressor by

unsoldering the twp winding leads.

Test for resistance

between the two winding Ie3ds and again

comvare

tO

the

data.

lESTIRGTHE

WINDING

lEADS

A

CAtmON:

[ON

SOLDERING]

When

StJidering,

use

a

large

enough

soldering

iron

to

get the job

done

quicldy.

Emessire

heat will

damage

the

diodes.

A/sD

make

certain

no

soldering

splashes

ollto the

windings

as

it

will melt the

insulation.

Check for continuity between

each

of

these

leads

and

the

rotor shaft. Continuity

would indicate a short

in

the rotor.

TESTING

THE

DIODES

With

the

diodes removed, measure the resistance

(as

shown) using a multitester (with a diode testing capability).

If

the

meter

measures resistance in one direction,

it

should

indicate infinity

in

the

other.

~

TESTING

DIODES

-~

ALTERNATE

STYLE

DIODE

Both diodes should

measure

the·same.resistance value.

If

one measures

lower

than

the

other,

it

is presumed faulty.

Replace both.

TESTING

THE

SUPPRESSOR

Unsolder the suppressor from

the

diode

and

check

for

infinite resistance.

IF

THE

SUPPRESSOR

FAlLS

TO

READ

JNRNITE

RESISTANCE.

THE

SUPPRESSOR

JS

FAULTY

A shorted suppressor will often

tum

black when shorted

out.

Repeat

the

same

test procedureS to the opposite side

rotor windings.

1-.v-IWESTERBEKE

l Engines

8t

Generators

2

BCGT

GENERATOR

ELECTRICAL

TESTING

0

TESTING

THE

EXCITER

WINDINGS

An

AC voltage is

induCed

in these windings by

the

rotating field.

Checking

the residual voltage output

from

this winding

can

determine

the

~ondition

of

the

wfuding

when

troubleshooting.

RESIDUAL

VOLTAGE

Single

capacitor

Model

16.

~

18

VAC

from

eath

winding

AC

voltage

can

be

measured across the capacitor· while the

generator is

operating.

This

voltlc,oe

may be a5 high

as

400

to

500 volts

AC.

This

voltage buildup is accomplished

as

the exciter

windings

charge the capacitor and the capacitor

discharges back

into

the exciter windings. This AC voltage

reading

is

taken

between

the #60 Hertz connector and the

number

conneCtion

plugged

in~

the capacitor while the

generator

is operating at its rated Hertz (61.5- 62.0). This

fiow

of

saturating

AC

fu

the

exciter windings produces a

phase-imbalance

type

of

field

that effects the

auxi1lary

windings: a

beneficial

result

that

produces good motor

starting characteristics for this type

of

generator.

IDlE: Position

the

m4ter

correctly

for

AC

voltage.

so as

not

ro

damage

·the

merer.

EXCITER

CIRCUIT

RESIDUAL

VOLTAGE

Madel4.5Kw

BC

16

VAC

(:!::

.5) ·

Madel7

.2Kw

BC

17

VAC

(:!::

.5)

Madel9.6Kw

BC

18

VAC

(:!::

.5)

CIIEClCING

RESIDUAL

VOLTAGE

TESDII·AC

.

VOLTAGE

(GEIIERATOR

llUHHIIIIi)

MEASURING

RESISTANCE

To

measure the resistance value

of

the

exciter windings,

locate

#9

and the #50 Hertz capacitor connections.

NOTE:

Three

numbered capacitor connections exist: #7,

#8,

tmd #9;

and

two

Hertz

connections,

#50

and

#60.

Unplug

any

other connections from the capacitor noting

their position on

the

capacitor. Place

one

lead

of

the

multimeter

on

plug .connection

#9

and

the

other lead on

plug

connection

#50

Hertz. Measure

the

resistance value

of

the exciter windings.

WINDING

RESISTANCE

[OHMS}

Modei4.SKw

BC

4.550

Ma~7~wBC

3J&Q

Madel9.6Kw

BC

3.710

NOTE:

Lower residual

voltag~

along with ti lower winding

resistimce.

will confirm aftmlty

winding.

CIIECDIG.

COtmiUITY

·

check to make sure there is no continuity

to

the

ground/generator case

from

either

of

the

two

leads.

Also check tbat no continuity exists between either

the

#60

Hettt plug

or

the

#8

plug

an~

any of the main stator

.winding leads on the AC output (not illustrated).

If

continuity is found here. a fault exists between

these:

two'~

winding groups. -

~~

DISCHARG.

THE

CAPACRORS

A

CAOTIOI:

t:apacifDIS

miiSI

be

dist:barged

before

fesfillg. t:apat:ifllls sfiii'B elet:lrit:ify

ami

t:aiJ

pat:lc

a lethal

1111111:11

eren

when

f/iSI:IInner:ted

tr11111

the

power

Sllllf't:e. . .

· Discharge the capacitor by a bridging the terminals with a

screwdriver.

l"'fiiiV'IWESiiRBEKE

. ) Engines & Generators

3

BCGT

GENERATOR

ELECTRICAL

TESTING

TESTING

THE

CAPACITORS

Connect

a multitester (highest ohm scale) to the capacitor

terminals.

The meter

should

go to zero

ohms

and slowly

return

to

high.

DisCharge

the

capacitor again and reverse

the

leads.

the

same

results

should

b~

obtained.

If

the

meter

.goes

down

and

stays

at

zero ohms, the capaci-

tor is faulty (shorted).

If

the

meter

fails

to

go

down

to zero, the capacitor

is.

faulty

{open

ciicuited).

Indications of a defective capacitor:

0 Infinite resistance,

or

no

rise in resistance

(shorted capacitor)

0

Infinite

resistance

(open

capacitor)

CAPACITOR

RATINGS

I

PART

NUMBERS

Model

4.5

Kw

BC

25

mfd

Pn#035985

Model

7.2

Kw

BC

31.5

mfd

Pnt/035978

Model

9.6

Kw

BC

35

mfd

Pn#041199

NOTe:

MAKE

CERTAIN

A

REPLACEMENT

CAPACITOR

HAS

THE

CORRECT

PART

NUMBER.

CHECK

THE

BODY

OF

THE

CAPACITOR

FOR

THE

RATING~

NOD.:

The

co.pocitor

rating

is~

on

the_

\ousmg

12

VOLT

EXCITAnON

The

generatOr

may

be

excited using 12

.volts

DC

taken

from the engine's starting battety.

This

voltage

is

applied

across

the

:#1:50

and

#9

leads

of

the exciter circuit windings

(unplugged)

with

any

other numbered leads unplugged

from the capacitors.

The

generator's

reaction during flash-

ing

will

help

detemUne

i~

fault. ·

12

VOLT

EXCrTAnON,

OUTPUT

RANGE

IS

22

TO

26

VAC.

0 A slight

rise

in

the

output.

voltage

with

the loading

of

the

engine and/or a growling noise from the generator

end will indicate a

fault

in the main stator windings.

0

No

rise

or a very slight rise

in

the output voltage

will

indicate a fault in the excitor windings.

0 Normal output voltage

as

specified above, check

excitor circuit

TESTING

THE

BA1TERY

CHARGING·CIRCUIT

:

Normal

AC

voltage running to tberecti1ier (while the

engine

is operating

at

3600

rpm)

is measured across the

two

AC

connections

o~

the bridge rectifier.

AC

VOLTAGE

TO

THE

BRIDGE

RECTIAER

(APPROXIMATELY):

No-load off

1he

generator

16.0

volts

AC

FIJU-Ioad

off the generator 17.5

volts

AC

BRIDGE

RECnFIER

Normal

DC

voltage running out

of

the

rectifier (in· volts

DC)

is

measured across the two

DC

connections

of

the

bridge

rectifier, that

is+

and-.

DC

VOLTAGE

FROM

THE

BRIDGE

RECnAER

fAPPROXIMATaY):

No-load

off

.the

generator

17

.o·

volts

DC

. .

FIJH-Ioad

off

the

generator 18.5

volts

DC

Uft

the

tw~

AC

wire

I'eacis

off the bridge rectifier and

measure the resistance between these two leads.

It

should

measure 0.14

ohm. No continuity should exist

~tween

there two leads and the ground

or.

the main stator windings.

ACLEAD

RESISTANCE

MEASUREMENT

Modei4.5Kw

BC@

60Hz

Model7

.2Kw

BC

@60Hz

@50Hz

Model

9.6Kw

BC

0

60Hz

@5oHz

.1570

Blue

to

Blue

.0940

Blue

to

Green

.1160

Blue

to

White

.O&Ul

Green

to

Blue

.10&n

.Blue

to

Wbite

ACTEKMINAL

I....,.I!ESI"ERBEICE

)Engines

& Generators

4

BCGT

GENERATOR

ELECTRICAL

TESTING

TESTING

THE

.BRIDGE

RECnFIER

(meter

used

- FLUKE

multim~ter)

.

A.

Set the meter

on

Ohms

scale.

B.

Connect

the positive (

+)

lead from the meter

to

point

#4.

Taking

the negative

(-)

lead, momentarily touch points

#1,

#2,

#3,

and

#5.

There

should

be

no

Ohm

value registered

on

the

meter.

C.

Remove

the

positive (+) lead from point #4

and

connect the

negativ~

(-) lead to

it

Momentarily touch

poin~

#1, #2

and

#3.

the

Qhm

meter should register

an

arbitrary

Ohm

value

at

each

point it touches.

D.

Leaving

the negative

(-)

lead

on

point #4, touch point

#5

with

the

positive ( +) lead. The meter should register

no

Ohm

value.

E.

Place

the positive(+) lead on point

#1

and

the negative(-)

lead

on

point #3. The meter again should register no

Ohm

value.

Reverse these connections and the meter should

register

no

Ohm

value.

If

the

rectifier fails

any

of

the

previous

tests B

through

E, replace

the

rectifier as

it

is defective. . #i. .

BRIDGE

~',

RECTIFIER

#4.

#3

when

Viewed

from

the top

Nlln:

Different

types

anillor

brands

of

test

meters

may

produce

opposite

test

results.

INTEGRAL

CORTROUER

The Integral Controller (LC.) is an encapsulated. solid-state

unit that

suppli~

a DC charging voltage to the generator's

starting

battery

while

the

generator is operating.

Charging

Voltage

13.0

-14.0

volts

DC

Charging

Amperage

0 -

17.0

amps

DC

A

seperate

group

of

stator

windings

supplies AC voltage to

a

brid~e

rectifier

which

converts the AC

cUITent

to supply

the

LC.

unit

The I.

C.

unit senses the

needS

of the starting

battery

and

supplies a DC charge when one is needed.

If

you

suspect

that

the

LC.

unit is faulty

(that

is,

if

the

battery's

charge

is

low), check the charging circuit and it's

·

components

as

described in

the

following

text

Check

all

connections

for

cleanliness and tightness including the

ground

before

replacing

the

I.C. uniL

NOTE:

When

the

generQlOr

is first staned, the LC. unit will

produce

a

low

charging

rate.

This

charging

rate

will

rise

as

the

generator

is

operated.

#2,

INTEGRAL

CONTROUER

--"'-1+

+

-

G'ND

AC

TESTING

THE

INTEGRAL

COITROUER

BRIDGE

RECTIAER

To

test the

battery

charger, put a multimeter between

the

positive ( +) and negative (-) leads to the battery. It

should

indicate 13.5V to

14V

with the engine running.

If

only

the

battery voltage

is

indicated, check that the battery

charger

teri:ninal

connections are

tight

With the unit running,

test

between

the

(+)

and (-) terminals for 13.5V

to

14V.

If

no

charge ia indicated, replace the charger.

FUSE

PROTECnDN

A 30 amp fuse protects the windings from a failure

of

the

bridge rectifier or integral controller (high amperage

or

a

short).

I..,...,.IWESJERBSCE

(Engines & Generators

5

BCGT

GENERATOR

ELECTRICAL

TESTING

TESTING

THE

MAIN

STATOR

WINDINGS

Residual voltage measured between the bot and neutral

leads will

be

7-8 volts AC. This.would be an indication

that the stator windings are okay. Check exciter windings

·and

artiQcially excite

the

generator..

Residual

Voltage

Check

Measure between bot

[#1

and #4] and neutral [#2 and #5].

Model4.5Kw

BC

8

VAC

(::!:

.5)

Model7

.2Kw

BC

7.5

VAC

(::!:

.5)

Model

9.6Kw

BC

7

·vAc

(:!:

.5)

IS

FASTERSIS

TO

STUD

Group

#1

- Measure resistance value between terminal

with lead

#l

and terminal with lead #3. (Check that there

is

no continuity

of

Group

#1

windings to

the

case

ground).

Group

#2

- Measure resistance value between terminal

with

lead

:fl:4

and terminal with lead #6. (Check that there

is

no continuity

of

group #2 windings to the case ground).

Check for a possible short between the

two

groups

of

stator windings by placing one lead

of

the multitester

on

the terminal with

the

stator #3 and the other lead

on

the

terminal with stator lead #6. There should be no continuity

between the two groups

of

stator windings.

MAIN

STATOR

WINDINGS

TESliNG

RESISTANCE

BETWEEN

THE

MAIN

STATOR

WINDINGS

Resistance

Valpes

[ohms]

Mode14.5Kw

BC

Between

lead$

____

11

and

12

___

.5150

11

and

#3

.5850 .

i4

and

i5

.5160

i4

and

16 .58SQ

Model7

.2Kw

BC

Between

leads

____

l1

and

l2

___

.294n

11

and

13

.330Q

i4

and

i5

.2930

i4

and

16 .331n

Model

9.6Kw

BC

Between

leads

____

i1

and

l2

___

.179n

11

and

13

.200Q

i4

and

15

.179n

i4

and

16 .201n

t....,-IWESIERBEICE

. · l Engines & Generators

6

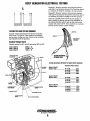

TWO

POLE

BC

GENERATOR

INTERNAL

WIRING

FUSE·

INTEGRAL

CONTROLLER

WINDING:

NO

TIM£

DELAY

Pn#43634

30A

250V

MDA-30

FUSE

•

ENGINE

PROTECTION

30A

(NOT

SHOWN)

Pn#33769

BA

250V

MTH-8

(TIME

DELAY)

r--------.,

B

UA.,-...,.1

I · I

lAR)j

I . I

I I

1·

1

I J

I I

1 I

I I

1 l

\ARJj

I I

I I

BRIDGE

RECTIFIER

A

..

ROTOR

WINDINGS

B •

BATTERY

CHARGE

WINDING

MODEL4.5Kw

ID

..

BATTERY

CHARGE

WINDING

MODELS

7.2Kw

AND

9.6Kw

C

·STATOR

WINDINGS

----------

11-----os

D

..

CAPACITOR

WINDING

UA-----os

CAPACITOR

RATINGS

I

PART

NUMBERS

Model4.5

Kw

BC

25

mtd

Pn#035985

Drrrn

Model?

.2

Kw

BC

31.5

mfd

Pn#035978

9 8 1

Model9.6

Kw

BC

35

mfd

Pn#041199

0 0 0

;

L:f

50Hz

NOTE:

MAKE

CERTAIN

A

REPLACEMENT

CAPACITOR

HAS

THE

CORRECT

PART

NUMBER.

CHECK

THE

BODY

OF

THE

CAPACITOR

FOR

THE

RATING.

CONNECT

FOR

1HE

REQUIRED

FREQUENCY

AND

OUTPUT

VOL

'lAG£

WINDING

RESISTANCE

VALUES

IN

OHMS

MODEl

4.5Kw

A

ROTOR

3.51!2

B

CHARGER

0.14!2

C

STATOR

0.58!2

D

EXCITER

2.3!2

MODEl

7.2Kw

A

ROTOR

3.51!2

8

CHARGER

0.14!2

. C

STATOR

0.29!2

D

EXCITER

2.20

MODEl9.6Kw

A

ROTOR

4.03!2

B

CHARGER

0.14!2

C

STATOR

0.17!2

AC

CONNECTIONS

CIRCUIT

BREAKER

:?1

- N

-

L

1-.------------~

s.--------,

~=

D

EXCITER

1.9!2

NOTE:

When

changing

from

60Hz

to

-50Hz.

make ceriain the ground wire is

properly

repositioned according to this

diagram.

N L

1-w'IWESTERBEKE

) Engines & Generators

7

12DVAC60Hz

(CONNECT

JUMPER)

230VAC50Hz

.

{REMOVE

JUMPER)

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

Westerbeke 7.0 BCDT - 50 Hz Guía del usuario

- Tipo

- Guía del usuario

en otros idiomas

Otros documentos

-

WEG AG10 Serie Manual de usuario

-

Hobart 5359D Operation and Maintenance Manual

-

WEG Synchronous alternators G line Manual de usuario

-

Sincro FB4 Use and Maintenance Manual

-

COOLRUN MUNICAP200 Guía de instalación

COOLRUN MUNICAP200 Guía de instalación

-

Campbell Hausfeld GW4502 Instrucciones de operación

-

Campbell Hausfeld GR2100 Manual de usuario

-

Campbell Hausfeld GN30c502AC Manual de usuario

-

Campbell Hausfeld GN5060 Manual de usuario

-

WEG Synchronous alternators G truck line Manual de usuario