Briteq BEAM WIZARD5x5 El manual del propietario

- Categoría

- Estroboscopios

- Tipo

- El manual del propietario

ENGLISH OPERATION MANUAL

BRITEQ

®

1/107 BEAM WIZARD5x5-RGBW

OPERATION MANUAL

Thank you for buying this Briteq

®

product. To take full advantage of all possibilities and for your own safety,

please read these operating instructions very carefully before you start using this unit.

FEATURES

All the power and possibilities of our BEAM MATRIX5x5-RGBW in a compact moving panel design !

High speed ENDLESS ROTATION pan/tilt movements with 16bit resolution and automatic X/Y re-

positioning for amazingly dynamic show programming. (also normal 270° tilt + 540°/630°pan available)

The unit is equipped with 25 extremely effective very narrow 4.5° lenses, in combination with powerful and

reliable 15W RGBW-leds.

This results in an exceptionally powerful “narrow beam” 5x5 Matrix effect projector that turns even the

biggest concerts and TV shows into an amazing spectacle! Light engineers will be amazed by the endless

possibilities and ease of use to create astonishing light shows!

You can use the full 116ch mode for full flexibility or use the vast internal RGBW-effects library (containing

letters, numbers, chases) so you only need 18ch to make professional shows using a small controller and

few channels.

Because of its high number of DMX channels this projector is equipped with Ethernet in/out and full

support for Art-Net protocol!.

RJ45 Ethernet in/out connections, equipped with automatic bypass function for increased reliability.

Internal Art-Net node: “Art-Net to DMX-conversion” 1 DMX-universe is available on the DMX-output.

Different DMX channel modes for different applications:

12 CH mode: PAN/TILT + RGBW+Dim+strobe+sound for all 25pixels together.

18 CH mode: same as the 12CH mode but with additional RGBW-effects library control.

110 CH mode: full control over all functions, including RGBW-control for all 25pixels separately.

116 CH mode: same as the 110CH mode but with additional RGBW-effects library control.

Excellent built-in programs for wonderful, ever changing, light shows.

RDM-functionality for easy remote setup: DMX addressing, channel mode, …

Very high 1200Hz LED refresh rate for flicker free use in TV-studios.

Silent operation, thanks to the temperature controlled “low airstream” cooling system.

The internal shows work in standalone or can be selected by DMX: static colors, fading colors, different

static chases, different sound activated chases.

The matrix LCD-display assures easy navigation in the different setup menus

Selectable lamp behavior: halogen lamp (slow) or led (fast)

Four dimmer curves: linear, square, inverse square, S-curve

In case of DMX failure you can choose between blackout and freeze mode.

Lock function to avoid unwanted altering of the settings.

Individual white balance for each pixel to perfectly match the colors of several projectors.

Default factory settings + user settings can be saved/loaded.

Neutrik PowerCON in/outputs: easy daisy chaining of several units.

Both 3pin & 5pin DMX in/outputs for maximum compatibility

Equipped with omega brackets for fast installation

High efficiency and low power consumption!

ENGLISH OPERATION MANUAL

BRITEQ

®

2/107 BEAM WIZARD5x5-RGBW

BEFORE USE

Before you start using this unit, please check if there’s no transportation damage. Should there be any, do

not use the device and consult your dealer first.

Important: This device left our factory in perfect condition and well packaged. It is absolutely necessary

for the user to strictly follow the safety instructions and warnings in this user manual. Any damage caused

by mishandling is not subject to warranty. The dealer will not accept responsibility for any resulting defects

or problems caused by disregarding this user manual.

Keep this booklet in a safe place for future consultation. If you sell the fixture, be sure to add this user

manual.

Check the contents:

Check that the carton contains the following items:

Operating instructions

BEAM WIZARD5x5-RGBW

PowerCON mains cable

2 omega brackets

SAFETY INSTRUCTIONS:

To protect the environment, please try to recycle the packing material as much as possible.

To prevent fire or shock hazard, do not expose this appliance to rain or moisture.

To avoid condensation to be formed inside, allow the unit to adapt to the surrounding temperatures when

bringing it into a warm room after transport. Condense sometimes prevents the unit from working at full

performance or may even cause damages.

This unit is for indoor use only.

Don’t place metal objects or spill liquid inside the unit. Electric shock or malfunction may result. If a foreign

object enters the unit, immediately disconnect the mains power.

Locate the fixture in a well ventilated spot, away from any flammable materials and/or liquids. The fixture

must be fixed at least 50cm from surrounding walls.

Don’t cover any ventilation openings as this may result in overheating.

Prevent use in dusty environments and clean the unit regularly.

Keep the unit away from children.

Inexperienced persons should not operate this device.

Maximum safe ambient temperature is 40°C. Don’t use this unit at higher ambient temperatures.

Make sure the area below the installation place is free from unwanted persons during rigging, de-rigging

and servicing.

Allow the device about 10 minutes to cool down before to start servicing.

Always unplug the unit when it is not used for a longer time or before to start servicing.

CAUTION: To reduce the risk of electric shock, do not remove

the top cover. No user-serviceable parts inside. Refer servicing

to qualified service personnel only.

The lightning flash with arrowhead symbol within the equilateral triangle is intended to alert the

use or the presence of un-insulated “dangerous voltage” within the product’s enclosure that may

be of sufficient magnitude to constitute a risk of electric shock.

The exclamation point within the equilateral triangle is intended to alert the user to the presence

of important operation and maintenance (servicing) instructions in the literature accompanying

this appliance.

This symbol means: indoor use only

This symbol means: Read instructions

This symbol determines: the minimum distance from lighted objects. The minimum distance

between light-output and the illuminated surface must be more than 1 meters

The device is not suitable for direct mounting on normally flammable surfaces. (suitable only for

mounting on non-combustible surfaces)

CAUTION: Do not stare at operating lamp.

May be harmful to the eyes.

ENGLISH OPERATION MANUAL

BRITEQ

®

3/107 BEAM WIZARD5x5-RGBW

The electrical installation should be carried out by qualified personal only, according to the regulations for

electrical and mechanical safety in your country.

Check that the available voltage is not higher than the one stated on the unit.

The power cord should always be in perfect condition. Switch the unit immediately off when the power cord

is squashed or damaged. It must be replaced by the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

Never let the power-cord come into contact with other cables!

This fixture must be earthed in order to comply with safety regulations.

Don’t connect the unit to any dimmer pack.

Always use an appropriate and certified safety cable when installing the unit.

In order to prevent electric shock, do not open the cover. Apart from the mains fuse there are no user

serviceable parts inside.

Never repair a fuse or bypass the fuse holder. Always replace a damaged fuse with a fuse of the same

type and electrical specifications!

In the event of serious operating problems, stop using the fixture and contact your dealer immediately.

The housing and the lenses must be replaced if they are visibly damaged.

Please use the original packing when the device is to be transported.

Due to safety reasons it is prohibited to make unauthorized modifications to the unit.

Important: Never look directly into the light source! Don’t use the effect in the presence of persons suffering

from epilepsy.

DESCRIPTION:

1. MAINS INPUT: equipped with original Neutrik PowerCON

®

. Connect the supplied mains cable or any

PowerCon

®

extension cable here.

2. MAINS OUTPUT: used to daisy chain the power to several other projectors. Always pay attention to the

maximum load while adding projectors! Special Multi cables (PowerCON

®

+ DMX XLR-cables are

optionally available: see our website!)

3. MAINS FUSE: protects the unit in case of electrical problems, always use the prescribed fuse!

4. DMX IN: both 3pin and 5pin inputs are available to daisy chain the projector with other units that will be

controlled by a DMX-controller. The DMX-inputs are also used to update the firmware of the projector,

see the upgrade instructions on our website.

ENGLISH OPERATION MANUAL

BRITEQ

®

4/107 BEAM WIZARD5x5-RGBW

5. DMX OUT: both 3pin and 5pin outputs are available to daisy chain the projector with other units that will

be controlled by a DMX-controller. While Art-Net is used, the DMX-outputs will carry the complete DMX-

universe you selected. (Art-Net node functionality).

6. ETHERNET IN/OUT: used to connect the projector to an Ethernet network, Art-Net protocol is supported.

7. [MENU] buttons: used to browse the different options of the setup menu.

MENU/ESC. Button: has several functions:

Enter the SETUP-menu: press shortly.

Enter the SETUP-menu while the display lock function is active: press during 3s.

Go 1 level up in the SETUP-menu: press shortly to go 1 level up.

Leave the SETUP-menu: press several times until the standard display is shown.

◄/►Buttons: mainly used to navigate in the SETUP-menu. The ►button is also used to rotate the

display over 180° (upsidedown).

▲/▼Buttons: mainly used to change the values of the selected function.

[ENTER]-button: used to confirm the current action.

8. DISPLAY: the backlit matrix LCD-display shows important information like:

channel mode, DMX-start/end address, IP-address, DMX-universe. The

backlight is lit soon as one of the buttons is pressed. The display blinks while the

DMX or Art-Net signal is lost.

9. BATTERY OPERATION Button: thanks to the internal battery you can browse

the SETUP-menu and change settings while the projector is disconnected from the mains.

10. MOUNTING BASE: the strong metal base is designed to be used with 2pcs “OMEGA BRACKET BIG”

(included) and an optional safety cable.

11. PAN/TILT LOCKING: used to lock the PAN/TILT movements during transport.

IMPORTANT: make sure to UNLOCK these handles before you switch the projector on!

12. COOLING FANS: during its operation the projector produces heat that must be dissipated. The fans

inside the projector must be able to evacuate the heat in the most effective way. Therefore is it very

important not to cover any of the ventilation openings as this may result in overheating.

OVERHEAD RIGGING

Important: The installation must be carried out by qualified service personal only. Improper

installation can result in serious injuries and/or damage to property. Overhead rigging requires

extensive experience! Working load limits should be respected, certified installation materials should

be used, the installed device should be inspected regularly for safety.

Make sure the area below the installation place is free from

unwanted persons during rigging, de-rigging and servicing.

Locate the fixture in a well ventilated spot, far away from any

flammable materials and/or liquids. The fixture must be fixed at

least 50cm from surrounding walls.

The device should be installed out of reach of people and outside

areas where persons may walk by or be seated.

Before rigging make sure that the installation area can hold a

minimum point load of 10times the device’s weight.

Always use a certified safety cable that can hold 12times the

weight of the device when installing the unit. This secondary safety

attachment should be installed in a way that no part of the

installation can drop more than 20cm if the main attachment fails.

The device should be well fixed; a free-swinging mounting is

dangerous and may not be considered!

Don’t cover any ventilation openings as this may result in

overheating.

The operator has to make sure that the safety-relating and

machine-technical installations are approved by an expert before

using them for the first time. The installations should be inspected

every year by a skilled person to be sure that safety is still optimal.

ENGLISH OPERATION MANUAL

BRITEQ

®

5/107 BEAM WIZARD5x5-RGBW

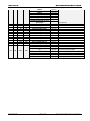

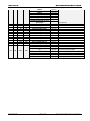

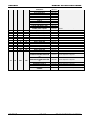

SETUP MENU

With the setup menu you can fully configure the projector. All settings are preserved when the unit is

disconnected from the mains.

ENGLISH OPERATION MANUAL

BRITEQ

®

6/107 BEAM WIZARD5x5-RGBW

General instructions for setup.

The SETUP-menu has three logically structured levels, see the menu structure on the previous page.

Press the [MENU] button to enter the SETUP-menu. (Press about 3s while Menu [LOCK] function is

active)

Press the ▲/▼/◄/► buttons to browse the different functions of the setup menu until the required function

is shown on the display.

Press the [ENTER] button to access the function and change its parameters.

Use ▲/▼ buttons to change the value.

Press the [ENTER] button again confirm.

To jump to a higher menu level: press the [MENU] button.

To exit the SETUP-menu: press the [MENU] button several times until the standard display is shown.

Remark: to make things easier you will always enter the SETUP-menu at the last used location.

[SET CONFIG > ADDRESS Set] –

All functions in this level are related to addressing of the unit.

[DMX-Address]

Used to set the desired DMX-address.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to select the desired DMX512 address. The last occupied DMX-address is also shown:

makes it easier to set the address of the next unit in the chain.

Once the correct address shows on the display, press the [ENTER] button to confirm.

Note: on RDM-compatible controllers this option can also be remotely set.

[IP-Address]

Used to set the IP address of the projector while controlled using the Ethernet ports.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼/◄/► buttons to set the desired IP-address.

Once the correct address shows on the display, press the [ENTER] button to confirm.

Remark: an IP address in ArtNet topology generally starts with 2.x.x.x or 10.x.x.x with 255.0.0.0 for netmask.

[IP-NetMask]

Used to set the Net Mask of the projector while controlled using the Ethernet ports.

Based on the IP-address the correct netmask is already set, you can still change it if really needed:

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to select the desired netmask, there are 3 options:

255.000.000.000

255.255.000.000

255.255.255.000

Once the correct option shows on the display, press the [ENTER] button to confirm.

[DMX Universe]

Used to set which DMX-universe should be used while controlled via the Ethernet ports.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to set the desired DMX universe (000 - 255).

Once the correct DMX universe shows on the display, press the [ENTER] button to confirm.

[IP Protocol]

Used to select which Ethernet protocol you want to use for communication.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to set the desired Protocol.

Once the correct protocol shows on the display, press the [ENTER] button to confirm.

Remark: currently only Art-Net is available, with future firmware updates extra protocols will be added.

ENGLISH OPERATION MANUAL

BRITEQ

®

7/107 BEAM WIZARD5x5-RGBW

[SET CONFIG > CHAN. Mode]

Used to set the desired channel mode.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to select the desired mode:

12 CH mode: [PAN/TILT] + RGBW+Dim+strobe+sound for all 25pixels together.

18 CH mode: same as the 12CH mode but with additional RGBW-effects library control.

110 CH mode: full control over all functions, including RGBW-control for all 25pixels separately.

116 CH mode: same as the 110CH mode but with additional RGBW-effects library control.

Once the correct option shows on the display, press the [ENTER] button to confirm.

[SET CONFIG > SHOW Config] –

All functions in this level are related to the automatic shows.

[NO DMX Mode]

Used to set how the projector reacts when the DMX-signal disappears.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to select the desired mode:

BLACKOUT: output turns black while no DMX is detected.

FREEZE: output based on the last valid DMX-signal is kept on the projector.

AUDIO: the projector starts working in audio mode.

Once the correct option shows on the display, press the [ENTER] button to confirm.

Note: as soon as the input detects a DMX-signal, blackout, freeze or audio mode will be cancelled.

[Install POS]

Used to select the installation position of the projector while used in standalone mode.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button to start editing.

Use the ▼/▲ buttons to select one of the available installation positions:

[Floor 180°]: Fixture is placed on the floor. [PAN/TILT] movements are not limited.

[CeilingHung]: Fixture is fixed on the ceiling. [TILT] movements are limited to ±60°.

[Stage Floor]: Fixture is placed on a stage, in front of the audience. The spot is always projecting

towards the audience’s direction; i.e. in front of the stage. [PAN] movement angle (left to right to left):

160°. [TILT] movement angle: 90° (60° above horizon; 30° below horizon.)

[Stage Hung]: Fixture is fixed upside-down on the ceiling of a stage. The spot is mainly projecting

towards the audience in front of the stage. [PAN] movement angle (left to right to left):160°. [TILT]

movement angle: 90° (vertically, front 75°; back 15°)

Once the right mode is shown on the display, press the [ENTER] button to confirm.

[SET CONFIG > MATRIX Set] –

All functions in this level are related to the 5x5 LED-Matrix panel.

[LedBehavior]

Used to select the reaction time of the projector.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to select the desired mode:

LED The projector follows the instructions instantly, no delay.

HALOGEN The projector imitates the behavior of a halogen lamp (slower reaction time).

Once the correct option shows on the display, press the [ENTER] button to confirm.

[DIM Curve]

Used to set the dimmer curve of the master dimmer.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to selected the desired curve:

ENGLISH OPERATION MANUAL

BRITEQ

®

8/107 BEAM WIZARD5x5-RGBW

Once you have the desired curve, press the [ENTER] button to save it.

[FLOW Invert]

Used to change the running direction of the chases.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to toggle between ON and OFF.

Press the [ENTER] button to confirm.

[MATRIX Rot.]

Used to select the position of LED Matrix compared to the base of the unit.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button to start editing.

Use the ▼/▲ buttons to select one of the available installation positions:

[Standard] - [90°] - [180°] - [-90° (270°)]

Once the right mode is shown on the display, press the [ENTER] button to confirm.

[SOUND Mode]

Used to adjust some of the settings for the LED Matrix while used in sound mode.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button.

Press ◄/► buttons to select one of the options:

[MIC Sense]: adapt the microphone sensitivity for the LED Matrix.

Press the [ENTER] button.

Use ▲/▼ buttons to change the value (000 – 099)

Press the [ENTER] button.

[Repeat]: adapt how many times a chase is played on the LED Matrix before the next one is shown.

Press the [ENTER] button.

Use ▲/▼ buttons to change the value (000 – 099)

Press the [ENTER] button.

[DMX/SOUND]: select if the LED Matrix is controlled by DMX or by audio while working in standalone.

Press the [ENTER] button.

Use ▲/▼ buttons to select:

DMX: the chases on the LED Matrix are selected from the internal library using DMX-control.

SOUND: the chases on the LED Matrix are running in full automatic audio mode.

Press the [ENTER] button.

ENGLISH OPERATION MANUAL

BRITEQ

®

9/107 BEAM WIZARD5x5-RGBW

[SET CONFIG > FIXTURE Set] –

This level contains some general settings.

[TILT Invert]

Used to select if the TILT movements are inverted or not.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to toggle between ON and OFF.

Press the [ENTER] button to confirm.

[PAN Invert]

Used to select if the PAN movements are inverted or not.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to toggle between ON and OFF.

Press the [ENTER] button to confirm.

[PAN Range]

Used to select the maximum range for the PAN movements.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to select the desired PAN range:

540° PAN range = 540° (or 1 ½ rotations)

630° PAN range = 630° (or 1 ¾ rotations)

Press the [ENTER] button to confirm.

[FEEDBACK]

This function corrects the PAN/TILT positions automatically if someone bumps into the machine.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to toggle between ON and OFF.

Press the [ENTER] button to confirm.

[STANDBY]

To save energy the projector goes in sleep mode after a certain time when no DMX is detected.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to select one of these options:

[OFF] standby function not used

[0xxM] The time (from 001 to 099 minutes) before the standby function is activated.

Press the [ENTER] button to confirm.

Remark: when during standby mode a DMX-signal is detected, the projector first performs a reset.

[FUNC. Delay]

On the Function channel (last channel of the DMX chart) you can select some special functions, like

“blackout during PAN/TILT” and others. With this option you can select the delay before a selected

function becomes active.

IMPORTANT INFORMATION: the function delay can only be set to zero seconds (no Delay) when you are

using a DMX-controller or DMX-software using presets for the DMX-values of the special functions.

Never use “no Delay” while using a simple DMX-controller with faders to set the functions manually!

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to select one of these options:

[NO Delay] special function is immediately activated

[1s Delay] special function is activated when the DMX-value is unchanged for 1s.

[2s Delay] special function is activated when the DMX-value is unchanged for 2s.

[3s Delay] special function is activated when the DMX-value is unchanged for 3s.

Press the [ENTER] button to confirm.

ENGLISH OPERATION MANUAL

BRITEQ

®

10/107 BEAM WIZARD5x5-RGBW

[SET CONFIG > FAN Set] –

On some occasions fan noise should be reduced to a minimum. Therefore you can set three different

fan speed modes.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to select one of these options:

[Auto]: the fan speed will be automatically adjusted to always have the best balance between fan

noise and performance (light output).

[Low]: the fan speed will always be low to reduce fan noise to a minimum. (use in theatres,

conference rooms, …). However this means that the LED temperature could become too high: in that

case the LED current will be reduced automatically to protect the LED. Light output will also be lower.

[High]: the LED will be well cooled so maximum light output can be guaranteed under all conditions.

However this means that fan noise will be higher than usual. While used in discotheques and in hot

summertime conditions this should not be a problem.

Press the [ENTER] button to confirm.

[SET CONFIG > DISPLAY Set] –

This level contains all display related settings.

[Backlight]

Used to adjust how long the display stays lit after the last time it was used.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to select one of these options:

[ON]: display is always lit.

[0xxM]: you can set the number of minutes before the display turns dark after it was last used.

Press the [ENTER] button to confirm.

[Flip 180]

Used to turn the display over 180°: [ON] = display is upsidedown.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to toggle between ON and OFF.

Press the [ENTER] button to confirm.

[AUTO LOCK]

Used to lock the setup menu against unwanted altering of the settings.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to toggle between ON and OFF.

Press the [ENTER] button to confirm.

Remark: while the display is locked you have to press the [MENU]-button for 3s to enter the setup menu.

[noDMX blink]

Used to select of the display should blink or not when the DMX/Art-Net signal was lost.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to toggle between ON and OFF.

Press the [ENTER] button to confirm.

[Temp C/F]

Used to select if the LED-temperature is shown in degrees Celcius [°C] or Fahrenheit [°F].

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to select one of these options:

[Celcius]: LED-temperature is shown in degrees Celcius [°C].

[Fahrenheit]: LED-temperature is shown in degrees Fahrenheit [°F].

Press the [ENTER] button to confirm.

ENGLISH OPERATION MANUAL

BRITEQ

®

11/107 BEAM WIZARD5x5-RGBW

[SET CONFIG > DEFAULTS] –

This is your emergency exit if you really messed up the settings: just return to PRO or AUTO preset.

Also 2 user settings can be saved/loaded.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ◄/► buttons to select one of these options:

[PRO Use]: optimized standard settings for professional control of the unit.

[AUTO Use]: optimized standard settings for easy automatic control of the unit.

[USER Def.]: you can adapt the PRO or AUTO settings and save the new parameters as your

personal USER-settings.

Press the [ENTER] button:

[PRO Use] or [AUTO Use] was selected: the display shows “LOAD”

Press the [ENTER] button and use ▲/▼ buttons to confirm YES / NO

Press the [ENTER] button to confirm.

[USER Def.] was selected: the display shows “LOAD”

Use ◄/► buttons to select LOAD / SAVE

Press the [ENTER] button and use ▲/▼ buttons to confirm YES / NO

Press the [ENTER] button to confirm.

[SAVE] was selected: the current settings of the setup menu are saved to memory.

[LOAD] was selected: the previously saved settings are loaded.

PARAMETER name

PRO defaults

AUTO defaults

USER defaults

[IP Protocol]

Artnet

Artnet

Current setting in the menu

[CHAN mode]

116 ch

18 ch

Current setting in the menu

[Install POS]

Floor 180°

Floor 180°

Current setting in the menu

[NO DMX mode]

Freeze

Audio

Current setting in the menu

[LED behaviour]

Halogen

Halogen

Current setting in the menu

[White Bal.]

NO factory default

NO factory default

Current white balance is saved

[DIM Curve]

Square

Square

Current setting in the menu

[FLOW invert]

OFF

OFF

Current setting in the menu

[MATRIX Rot.]

standard

standard

Current setting in the menu

[MIC Sense]

85%

85%

Current setting in the menu

[Chase Repeat]

3

3

Current setting in the menu

[PAN invert]

OFF

OFF

Current setting in the menu

[TILT invert]

OFF

OFF

Current setting in the menu

[PAN Range]

540

540

Current setting in the menu

[FEEDBACK]

ON

ON

Current setting in the menu

[FUNC. Delay]

3 sec

3 sec

Current setting in the menu

[STANDBY]

15 M

OFF

Current setting in the menu

[HEAD Fan]

AUTO

AUTO

Current setting in the menu

[BASE Fan]

AUTO

AUTO

Current setting in the menu

[Backlight]

2 min.

ON

Current setting in the menu

[AUTO LOCK] Menu

OFF

OFF

Current setting in the menu

[no DMX blink] display

ON

OFF

Current setting in the menu

[Temp C/F]

Celcius

Celcius

Current setting in the menu

[SET CONFIG > TIMERS] –

Shows the time the projector was used.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ◄/► buttons to select one of these options:

[Total Time]: The total time the unit was used since it was used for the 1

st

time, non resettable.

[Last JOB]: The time the unit was used on the last job. This timer can be reset in the (hidden)

calibration menu.

Press the [ENTER] button to confirm.

ENGLISH OPERATION MANUAL

BRITEQ

®

12/107 BEAM WIZARD5x5-RGBW

[INFORMATION > LED Temp.] –

Shows the actual temperature of the LEDs.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the LED temperature is shown.

[INFORMATION > ERROR info] –

Shows information about eventual errors.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button:

No errors: display shows [NONE]

Errors to report: the error will be shown on the display so you can take action.

[INFORMATION > DMX values] –

Shows the function and DMX-value for the last used DMX channel: used for problem solving

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the display shows the function and DMX-value of the last used channel.

Use a DMX-controller to control the projector: every time a value on one of the DMX-channels was

changed, the information will be shown on the display.

[INFORMATION > Model Name] –

Shows the name of the projector.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the display shows [BEAMWIZARD5x5].

[INFORMATION > Firmware V.] –

Shows the current firmware version in the projector.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the display shows the firmware versions of the different processors in the

projector: 1U01, 2U01, 3U01, 4U01

Note: The firmware of this unit can be upgraded using a special upgrade tool with Windows

®

software.

(separately available from Briteq). More information about this can be found in the user manual of the

upgrade tool and / or our website: www.briteq-lighting.com

[TEST/RESET > AUTO TEST] –

Used to start the automatic test function: all functions will be tested.

Important: use the projector in STANDALONE (NO DMX or Ethernet connection)

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the projector starts an automatic AUTOTEST program until you stop it.

Press the [MENU] button to stop the program.

[TEST/RESET > RESET Menu ] –

Used to reset certain functions of the projector.

Press the ▲/▼/◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the display shows [PAN/TILT] (the only option, no other functions to reset)

Press the [ENTER] button again to start resetting.

ENGLISH OPERATION MANUAL

BRITEQ

®

13/107 BEAM WIZARD5x5-RGBW

CALIBRATION MENU

This is a hidden menu where you can fine-tune the offset of several functions. To access this menu do as

follows: press the [ENTER] button for about 3seconds while you are in the SETUP menu (any option, not

important). Now the calibration menu shows up:

[Reset JOB]

Used to reset the [Last JOB] timer.

Press the ◄/► buttons until the desired function is showing on

the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to toggle between NO and YES.

Press the [ENTER] button to confirm.

[SET WHITE B] (set white balance)

Used to adjust the white balance or to perfectly match the colors of several projectors.

Press the ◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the display shows [LED 001]

Use the ▲/▼ buttons to select the number of the LED (001 → 025) that you want to adjust.

Press the [ENTER] button to confirm: the display shows the 4 colors whith their current value:

[R] [G] [B] [W]

xxx xxx xxx xxx

Remark: (xxx is the current value of the selected color: [R](red), [G](green), [B](blue), [W](white)

Press the ◄/► buttons to select the desired color.

Use the ▲/▼ buttons to change the values of the selected color (from 050 to 255).

Press the [ENTER] button to confirm.

Use the ▲/▼ buttons to select the number of the next LED (001 → 025) that you want to adjust.

… repeat the actions until the white balance of all pixels is set.

Important notes:

The setting of this option affects all color settings, static colors and DMX-controlled colors.

It is highly recommended to save the new white balance settings to [USER Def.] (USER default

settings memory) to preserve the settings.

[Set PAN]

Used to adjust the home position of the PAN movement.

Press the ◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to adjust the home position of the PAN movement: -127 to +128

Press the [ENTER] button to confirm.

[Set TILT]

Used to adjust the home position of the TILT movement.

Press the ◄/► buttons until the desired function is showing on the display.

Press the [ENTER] button: the values can be changed

Use ▲/▼ buttons to adjust the home position of the TILT movement: -127 to +128

Press the [ENTER] button to confirm.

ENGLISH OPERATION MANUAL

BRITEQ

®

14/107 BEAM WIZARD5x5-RGBW

ELECTRICAL INSTALLATION

Important: The electrical installation should be carried out by qualified personal only,

according to the regulations for electrical and mechanical safety in your country.

STANDALONE WITH BUILT-IN CHASES:

Use this function when you want an instant show on only 1 projector.

Connect the projector to the mains and turn it on.

In the setup menu:

Load the [AUTO Use] defaults.

If needed: adapt the [Install POS.] settings

ELECTRICAL INSTALLATION FOR TWO OR MORE UNITS IN DMX-MODE:

Use this function when you want to control the projectors by any DMX controller.

Connect the projectors as shown in the drawing below.

First put the projectors in the desired DMX-mode: see the different DMX-charts and choose the one that

suits you best.

Give all projectors a start address: each projector shows its start + end address, make sure that the

addresses do not overlap!

Some general information on DMX:

The DMX-protocol is a widely used high speed signal to control intelligent light equipment. You need to

“daisy chain” your DMX controller and all the connected units with a balanced cable of good quality.

Both XLR-3pin and XLR-5pin connectors are used, however XLR-3pin is more popular because these

cables are compatible with balanced audio cables.

Pin layout XLR-3pin: Pin1 = GND ~ Pin2 = Negative signal (-) ~ Pin3 = Positive

signal (+)

Pin layout XLR-5pin: Pin1 = GND ~ Pin2 = Negative signal (-) ~ Pin3 = Positive

signal (+) ~ Pins4+5 not used.

To prevent strange behavior of the light effects, due to interferences, you must use

a 90Ω to 120Ω terminator at the end of the chain. Never use Y-splitter cables, this simply won’t work!

Make sure that all units are connected to the mains.

Each light effect in the chain needs to have its proper starting address so it knows which commands

from the controller it has to decode.

ELECTRICAL INSTALLATION VIA ETHERNET IN/OUT:

Art-Net is nothing more than a protocol for transmitting DMX512 over an Ethernet network, developed by

Artistic Licence Engineering (UK) Ltd. Thanks to the much bigger bandwidth it is possible to send more than

256 DMX-universes in one time.

This projector can be connected in such Ethernet network using routers, switches etc. The network topology

is exactly the same as for a normal PC-network. However, IP-addresses cannot be obtained via DHCP: see

the explanations in the chapter “setup menu” on how to manually setup the IP-address, Net Mask and

choose the desired DMX-universe.

IMPORTANT NOTE: this projector has both Ethernet input and output so you can daisy chain several units.

However the number of units in one chain should be limited to ±10 units to avoid unwanted signal delays. In

bigger installations you should use the “STAR-topology” using Ethernet switches (or a combination of both):

ENGLISH OPERATION MANUAL

BRITEQ

®

15/107 BEAM WIZARD5x5-RGBW

Internally the selected DMX-universe is treated as a normal DMX-signal so further setup of the DMX-

address, channel mode etc. should be done as usual.

Thanks to the internal Art-Net node all 512 channels of the selected DMX-universe are automatically

converted from Art-Net to the DMX-output: they can be used to control other DMX-equipment:

RDM FUNCTIONS / REMOTE SETUP

RDM means “Remote Device Management”. This projector works with a brief set of RDM-functions which

means that it can setup a bi-directional communication with an RDM-compatible DMX-controller. Some of

these functions are briefly explained below, others will be added in the future.

The DMX-controller sends out a “discovery command”, all RDM devices respond and send their unique

device ID.

The DMX-controller asks each RDM device for some basic data so it knows which devices are connected.

The projector will respond:

Device name: BEAM WIZARD5x5

Manufacturer: Briteq®

Category: LED Dimmer

Firmware: x.x.x.x (firmware version of the projector)

DMX address: xxx (current DMX start address of the projector)

DMX footprint: xx (number of DMX-channels used by the projector)

Personality: xx (current personality [or DMX-working mode] used by the projectors)

The DMX-controller can send certain commands to each RDM device which allow remote setup of the

units. Thanks to this the projector can be setup remotely.

The following functions can be managed remotely:

No more need to take a ladder and set all units one by one!

DMX START ADDRESS: The start address can be set remotely from 001 to xxx.

PERSONALITY: The DMX working mode (DMX-chart) can be set remotely.

These 2 functions make it possible to prepare a complete DMX-patch of all projectors on the DMX-

controller and send these data to all projectors at once. More functions will be added later.

ENGLISH OPERATION MANUAL

BRITEQ

®

16/107 BEAM WIZARD5x5-RGBW

DMX CHARTS

4 Different DMX channels modes are available:

12CH

18CH

110CH

116CH

Functions

DMX

Descriptions

1

1

1

1

PAN 8bit

000-255

Pan (0~540° or 0~630°)

2

2

PAN 16 bit

000-255

Pan in 16 bit precision

2

2

3

3

PAN Rotation

000-127

Pan Stop (no function)

128-189

Pan Speeds in CW from fast to slow

190-193

Pan stop (no rotation)

194-255

Pan Speeds in CCW from slow to fast

3

3

4

4

TILT 8bit

000-255

Tilt(0~270°)

5

5

TILT 16 bit

000-255

Tilt in 16 bit precision

4

4

6

6

TILT Rotation

000-127

Tilt Stop (no function)

128-189

Tilt Speeds in CW from fast to slow

190-193

Tilt stop (no rotation)

194-255

Tilt Speeds in CCW from slow to fast

5

5

7

7

PAN/TILT Speed

000-255

Pan & Tilt Speeds from fast to slow

6

6

Red (all pixels)

000-255

0-100%

7

7

Green (all pixels)

000-255

0-100%

8

8

Blue (all pixels)

000-255

0-100%

9

9

White (all pixels)

000-255

0-100%

10

10

8

8

Master dimmer

000-255

0-100%

11

11

9

9

Strobe / Shutter effect

Strobe / Shutter effect

000 - 007

Shutter closed (no output)

008 - 015

Shutter open

016 - 131

Strobe 1 (slow → fast)

132 - 139

Shutter open

140 - 181

Strobe 2: slow open / instant close (slow → fast)

182 - 189

Shutter open

190 - 231

Strobe 3: instant open / slow close (slow → fast)

232 - 239

Shutter open

240 - 247

Strobe 4: random strobe

248 - 255

Shutter open

12

10

FX channels in blackout

000-000

Master dimmer for the effect patterns

FX dimmer (0-100%)

001-255

13

11

Playback speed = zero

000-007

Select FX Sequence steps or playback speed

for the max. 32 steps in the selected effect

sequence (CH4)

Playback speed, fast to slow

008-120

Sequence step 1 selected

121-123

Sequence step 2 selected

124-127

Sequence step 3 selected

128-131

Sequence step x selected

…

Sequence step 32 selected

246-249

Reset playback to step 1

250-255

14

12

FX Group 1 selected

000-031

Select FX Group (choose one of the 8 Groups,

each containing 16 effect sequences)

FX Group 2 selected

032-063

FX Group 3 selected

064-095

FX Group x selected

…

FX Group 7 selected

192-223

FX Group 8 selected

224-255

15

13

FX Sequence 1 selected

000-012

Select FX Sequence (choose one of the 16

effect sequences in the FX group selected with

CH3)

FX Sequence 2 selected

013-024

FX Sequence 3 selected

025-036

FX Sequence x selected

…

FX Sequence 14 selected

157-168

FX Sequence 15 selected

169-180

FX Sequence 16 selected

181-255

16

14

Red

000-012

Select FX Color (with this channel the color of

the effect patterns is selected)

Green

013-024

Blue

025-036

Red/Green

037-048

Green/Blue

049-060

ENGLISH OPERATION MANUAL

BRITEQ

®

17/107 BEAM WIZARD5x5-RGBW

Red/Blue

061-072

Red/Green/Blue

073-084

Color 1

085-096

Color 2

097-108

Color 3

109-120

Color 4

121-132

Color 5

133-144

Color 6

145-156

Color 7 (WW: Warm White)

157-168

Color 8 (CW: Cool White)

169-180

CFADE, slow to fast

181-255

Color fade, slow to fast with increasing value

17

15

Background not active

000-012

Select background Color(with this channel the

color of the effect background is selected)

Red

013-024

Green

025-036

Blue

037-048

Red/Green

049-060

Green/Blue

061-072

Red/Blue

073-084

Red/Green/Blue

085-096

Color 1

097-108

Color 2

109-120

Color 3

121-132

Color 4

133-144

Color 5

145-156

Color 6

157-168

Color 7 (WW: Warm White)

169-180

Color 8 (CW: Cool White)

181-192

CFADE, slow to fast

193-255

Color fade, slow to fast with increasing value

10

16

Red (pixel 01)

000-255

11

17

Green (pixel 01)

000-255

12

18

Blue (pixel 01)

000-255

13

19

White (pixel 01)

000-255

14

20

Red (pixel 02)

000-255

15

21

Green (pixel 02)

000-255

16

22

Blue (pixel 02)

000-255

17

23

White (pixel 02)

000-255

…

…

pixels 03 to 24

106

112

Red (pixel 25)

000-255

107

113

Green (pixel 25)

000-255

108

114

Blue (pixel 25)

000-255

109

115

White (pixel 25)

000-255

12

18

110

116

No function

000-069

Activate PAN/TILT Blackout (*)

070-079

executed after 3seconds

Disable PAN/TILT Blackout (*)

080-089

executed after 3seconds

No function

090-099

Reset ALL (*)

100-109

executed after 3seconds

No function

110-149

SOUND ACTIVATED MODE

150-255

Audio sensitivity: 150=low ~ 255=high

ENGLISH OPERATION MANUAL

BRITEQ

®

18/107 BEAM WIZARD5x5-RGBW

MAINTENANCE

Make sure the area below the installation place is free from unwanted persons during servicing.

Switch off the unit, unplug the mains cable and wait until the unit has been cooled down.

During inspection the following points should be checked:

All screws used for installing the device and any of its parts should be tightly fastened and may not be

corroded.

Housings, fixations and installations spots (ceiling, truss, suspensions) should be totally free from any

deformation.

When an optical lens is visibly damaged due to cracks or deep scratches, it must be replaced.

The mains cables must be in impeccable condition and should be replaced immediately when even a

small problem is detected.

In order to protect the device from overheat the cooling fans (if any) and ventilation openings should be

cleaned monthly.

The interior of the device should be cleaned annually using a vacuum cleaner or air-jet.

The cleaning of internal and external optical lenses and/or mirrors must be carried out periodically to

optimize light output. Cleaning frequency depends on the environment in which the fixture operates: damp,

smoky or particularly dirty surroundings can cause greater accumulation of dirt on the unit’s optics.

Clean with a soft cloth using normal glass cleaning products.

Always dry the parts carefully.

Attention: We strongly recommend internal cleaning to be carried out by qualified personnel!

SPECIFICATIONS

This unit is radio-interference suppressed. This product meets the requirements of the current European and

national guidelines. Conformity has been established and the relevant statements and documents have been

deposited by the manufacturer.

Mains Input: AC 100V - 240V, 50/60Hz

Power consumption: 415 Watt max.

Fuse: 250V T4A (20mm glass)

Sound Control: Internal microphone

Ethernet connections: RJ45 in / out

DMX connections: 3pin + 5pin XLR male / female

DMX channels used: 12 modes (4 to 150CH)

Lamp: 25x RGBW 15W

LED Refresh rate: 1200 Hz

Beam Angle: 4.5°

Size: see drawings at the end of this user manual.

Weight: 20.8 kg

"Art-Net™ Designed by and Copyright Artistic Licence Holdings Ltd"

The information might be modified without prior notice

You can download the latest version of this user manual on our website: www.briteq-lighting.com

FRANÇAIS

GUIDE D’UTILISATION

BRITEQ

®

19/107 BEAM WIZARD5x5-RGBW

GUIDE D’UTILISATION

Nous vous remercions d’avoir acheté ce produit Briteq

®

. Pour tirer pleinement profit de toutes les possibilités

du produit et pour votre propre sécurité, lisez ces instructions très attentivement avant d’utiliser cet appareil.

CARACTÉRISTIQUES

Toute la puissance et les fonctions de notre BEAM MATRIX5x5-RGBW sont maintenant aussi disponible

dans ce projecteur compact « panneau mobile » !

Mouvements PAN/TILT à ROTATION INFINIE et haute vitesse avec une résolution de 16 bits et un

repositionnement automatique X/Y pour une programmation de show incroyablement dynamique.

(Fonction normale d’inclinaison à 270° et de panoramique à 540°/630° également disponible)

Ce projecteur est équipé de 25 lentilles très étroites et extrêmement efficaces de 4,5°, combinées avec

des LED RGBW fiables et puissantes de 15 W.

Il en résulte un projecteur 5x5 à effet matrice et à faisceau étroit incroyablement puissant qui peut

transformer les plus grands concerts et émissions télévisées en un spectacle époustouflant ! Les

ingénieurs lumière seront émerveillés par les possibilités infinies et la facilité d’utilisation pour créer des

jeux de lumière extraordinaires !

Il est possible d’utiliser le mode intégral 116CH pour une totale flexibilité ou d’utiliser la riche bibliothèque

interne d’effets RVB et blanc (contenant des lettres, des chiffres, des chenillards) de sorte que vous

n’aurez besoin que du mode 18CH pour créer des shows professionnels à l’aide d’un petit contrôleur et de

quelques canaux.

En raison de son grand nombre de canaux DMX, ce projecteur est équipé d’une entrée/sortie Ethernet et

prend en charge le protocole Art-Net !

Connexions d’entrée/sortie Ethernet RJ45, équipées d’une fonction de dérivation (bypass) automatique

pour une fiabilité accrue.

Nœud Art-Net interne : Un univers DMX de « conversion Art-Net vers DMX » est disponible sur la sortie

DMX.

Divers modes de canaux DMX pour différentes applications :

Mode 12CH : PAN/TILT + RVB et blanc + stroboscope + son pour l’ensemble des 25 pixels.

Mode 18CH : identique au mode 12CH mais en plus un contrôle de la bibliothèque d’effets RVB et

blanc.

Mode 110CH : contrôle total de toutes les fonctions, y compris un contrôle séparé RVB et blanc des

25 pixels.

Mode 116CH : identique au mode 110CH mais en plus un contrôle de la bibliothèque d’effets RVB et

blanc.

Excellents programmes intégrés offrant de fabuleux jeux de lumière en changement perpétuel.

Fonctionnalité RDM pour faciliter la configuration à distance : Adressage DMX, mode canal, ...

LED à fréquence de rafraîchissement très élevée de 1200 Hz permettant d’éviter le scintillement dans les

studios TV.

Fonctionnement silencieux grâce au système de refroidissement à « faible courant d’air ».

Les shows internes peuvent être employés en mode autonome ou sélectionnés par DMX : couleurs

statiques, fondu de couleurs, divers chenillards statiques, divers chenillards à commande sonore.

L’écran LCD à matrice assure une navigation facile à travers les différents menus de configurations

Comportement des leds au choix : lampe halogène (lente) ou led (rapide)

Quatre courbes de variation de l’intensité : linéaire, carré, carré inversé, courbe en S

En cas d’échec DMX, les modes « tout éteint » ou « maintien » resteront disponibles.

Fonction de verrouillage afin d’empêcher les modifications indésirables de la configuration.

Balance des blancs individuelle pour chaque pixel afin de s’accorder parfaitement avec les couleurs de

plusieurs projecteurs.

Les réglages par défaut d’usine et les réglages personnels peuvent être mémorisés/chargés.

Entrées/sorties Neutrik PowerCon : chaînage facile de plusieurs unités.

Entrées/sorties DMX 3 et 5 broches pour une compatibilité maximale

Équipé de supports Omega pour une installation rapide

Haute efficacité et faible consommation d’énergie !

FRANÇAIS

GUIDE D’UTILISATION

BRITEQ

®

20/107 BEAM WIZARD5x5-RGBW

AVANT UTILISATION

Avant d’utiliser cet appareil, vérifiez ‘qu’il n’a pas été endommagé durant le transport. En cas de

dommages, n’utilisez pas l’appareil et consultez immédiatement votre revendeur.

Important : Cet appareil est expédié de notre usine en parfait état et bien emballé. Il est absolument

nécessaire que l’utilisateur suive strictement les instructions et les avertissements de sécurité se trouvant

dans ce manuel. Tout dommage dû à une mauvaise manipulation n’est pas couvert par la garantie. Le

revendeur n’accepte aucune responsabilité pour tous les défauts et problèmes dus au non-respect de ce

manuel.

Conservez ce manuel dans un endroit sûr pour toute consultation future. Si vous vendez l’appareil,

assurez-vous de joindre ce manuel.

Vérifiez le contenu :

Vérifiez que le carton contient les éléments suivants :

Instructions d’utilisation

BEAM WIZARD5x5-RGBW

Câble d’alimentation PowerCON

2 attaches Omega

INSTRUCTIONS DE SÉCURITÉ :

Pour protéger l’environnement, essayez de recycler autant que possible les matériaux d’emballage.

Pour éviter tout incendie ou électrocution, n’exposez pas cet appareil à la pluie ou à l’humidité.

Pour éviter une formation de condensation interne, laissez l’appareil s’adapter à la température ambiante

quand vous le mettez dans une pièce chaude après le transport. La condensation empêche parfois

l’appareil de fonctionner à plein rendement ou peut même causer des dommages.

Cet appareil est destiné à un usage intérieur seulement.

Ne placez pas d’objets métalliques et ne renversez pas de liquides à l’intérieur de l’appareil. Un choc

électrique ou un dysfonctionnement peut en résulter. Si un corps étranger pénètre dans l’appareil,

débranchez immédiatement le cordon d’alimentation de la prise secteur.

Placez l’appareil dans un endroit bien aéré, loin de tout matériau et/ou liquide inflammable. L’appareil doit

être fixé à au moins 50 cm des murs environnants.

Ne couvrez pas les ouvertures de ventilation, cela pourrait entraîner une surchauffe.

Évitez une utilisation dans des environnements poussiéreux et nettoyez l’appareil régulièrement.

Gardez l’appareil hors de la portée des enfants.

Les personnes inexpérimentées ne doivent pas utiliser cet appareil.

La température ambiante de fonctionnement maximale est de 40°C. N’utilisez pas cet appareil à des

températures ambiantes plus élevées.

ATTENTION : Pour réduire le risque de choc électrique, ne

retirez pas le panneau supérieur. L’appareil ne contient aucun

composant réparable par l’utilisateur. Confiez toute réparation à

un personnel qualifié uniquement.

Le symbole de l’éclair à l’intérieur d’un triangle équilatéral est destiné à alerter l’utilisateur de la

présence de « tensions dangereuses » non isolées à l’intérieur de l’appareil, d’une magnitude

pouvant constituer un risque d’électrocution.

Le symbole du point d’exclamation dans un triangle équilatéral sert à avertir l’utilisateur que

d’importants conseils d’utilisation et de maintenance sont fournis dans la documentation

accompagnant l’appareil.

Ce symbole signifie : pour un usage intérieur uniquement

Ce symbole signifie : lisez les instructions

Ce symbole définit : la distance minimale requise avec les objets éclairés. La distance minimale

entre la sortie de lumière et la surface éclairée doit être supérieure à 1 mètre

Cet appareil n’est pas adapté pour un montage direct sur des surfaces normalement

inflammables. (ne convient que pour le montage sur surfaces non combustibles)

ATTENTION : Ne fixez pas votre regard sur une lampe allumée.

Peut être nocif pour les yeux.

FRANÇAIS

GUIDE D’UTILISATION

BRITEQ

®

21/107 BEAM WIZARD5x5-RGBW

Assurez-vous qu’aucune personne étrangère ne se trouve dans la zone en dessous de l’emplacement

d’installation durant le montage, le démontage et l’entretien.

Laissez environ 10 minutes à l’appareil pour refroidir avant de commencer l’entretien.

Débranchez toujours l’appareil lorsqu’il ne va pas être utilisé pendant une longue période ou avant de

commencer l’entretien.

L’installation électrique doit être effectuée par du personnel qualifié, conformément à la réglementation en

matière de sécurité électrique et mécanique dans votre pays.

Vérifiez que la tension secteur n’est pas supérieure à celle indiquée sur l’appareil.

Le cordon d’alimentation doit toujours être en parfait état. Éteignez immédiatement l’appareil dès que le

cordon d’alimentation est écrasé ou endommagé. Il doit être remplacé par le fabricant, son agent de

service ou une personne de même qualification afin d’éviter tout danger.

Ne laissez jamais le cordon d’alimentation entrer en contact avec d’autres câbles !

Ce luminaire doit être mis à la terre pour être conforme à la réglementation en matière de sécurité.

Ne connectez pas l’appareil à un variateur de lumière.

Utilisez toujours un câble de sécurité approprié et certifié lors de l’installation de l’appareil.

Afin d’éviter un choc électrique, n’ouvrez aucun panneau. Aucune pièce interne n’est remplaçable par

l’utilisateur à part le fusible secteur.

Ne réparez jamais un fusible et ne court-circuitez jamais le porte-fusible. Remplacez toujours un fusible

endommagé par un fusible du même type ayant les mêmes spécifications électriques !

En cas de sérieux problèmes de fonctionnement, cessez d’utiliser l’appareil et contactez immédiatement

votre revendeur.

Le boîtier et les lentilles optiques doivent être remplacés s’ils sont visiblement endommagés.

Utilisez l’emballage d’origine pour transporter l’appareil.

Pour des raisons de sécurité, il est interdit d’apporter des modifications non autorisées à l’appareil.

Important : Ne regardez jamais directement la source de lumière ! N’utilisez pas le jeu de lumière en

présence de personnes souffrant d’épilepsie.

DESCRIPTION :

1. ENTRÉE SECTEUR : équipée d’un connecteur d’origine Neutrik PowerCON

®

. Branchez le câble

d’alimentation fourni ou tout câble de rallonge PowerCon

®

ici.

FRANÇAIS

GUIDE D’UTILISATION

BRITEQ

®

22/107 BEAM WIZARD5x5-RGBW

2. SORTIE SECTEUR : permet de mettre en série l’alimentation de plusieurs autres projecteurs. Faites

toujours attention à la charge maximale lors de l’ajout d’autres projecteurs ! Des câbles multiples

(PowerCON

®

+ DMX XLR, sont disponibles en option : reportez-vous à notre site Internet !)

3. FUSIBLE SECTEUR : protège l’unité en cas de problèmes électrique. Utilisez toujours un fusible de type

recommandé !

4. ENTRÉE DMX : des entrées à 3 et 5 broches sont disponibles pour mettre en série le projecteur avec

d’autres unités qui seront commandées par un contrôleur DMX. Les entrées DMX servent également à

mettre à jour le micrologiciel du projecteur ; voir les instructions de mise à jour sur notre site Web.

5. SORTIE DMX : des sorties à 3 et 5 broches sont disponibles pour mettre en série le projecteur avec

d’autres unités qui seront commandées par un contrôleur DMX. Lorsque le protocole Art-Net est utilisé,

les sorties DMX supportent l’intégralité de l’univers DMX que vous avez sélectionné. (fonctionnalité de

nœud Art-Net).

6. ENTRÉE/SORTIE ETHERNET : permet de connecter le projecteur à un réseau Ethernet ; le protocole

Art-Net est pris en charge.

7. Touche [MENU] : permet de parcourir les différentes options du menu des réglages.

Touche MENU/ESC. : permet plusieurs fonctions :

Accéder au menu des RÉGLAGES : un appui bref.

Accéder au menu des RÉGLAGES en mode d’affichage verrouillé : un appui pendant 3 s.

Monter d’un niveau dans le menu des RÉGLAGES : un appui bref.

Quitter le menu des RÉGLAGES : un appui répété jusqu’au retour à l’affichage normal.

Touches ◄/► : permet principalement de parcourir le menu des RÉGLAGES. La touche ► permet

aussi de retourner l’affichage à 180° (inversé).

Touches ▲/▼ : permet principalement de modifier les valeurs de la fonction

sélectionnée.

Touche [ENTER] : permet de confirmer l’opération actuelle.

8. AFFICHEUR : l’écran LCD à matrice rétroéclairé affiche les informations

importantes tel que : mode de canal, début/fin d’adresse DMX, adresse IP,

univers DMX. Le rétroéclairage est actif dès qu’une touche est appuyée. L’écran

clignote lorsque le signal DMX ou Art-Net est perdu.

9. TOUCHE DE FONCTIONNEMENT SUR BATTERIE : grâce à la batterie interne, il est possible de

parcourir le menu des réglages et d’effectuer des modifications alors que le projecteur est débranché de

l’alimentation secteur.

10. SOCLE DE MONTAGE : le socle métallique résistant s’utilise avec les 2 supports « OMEGA BRACKET

BIG » (fournis) et un filin de sécurité facultatif.

11. VERROU DE PANORAMIQUE/INCLINAISON : permet de bloquer les mouvements de

PANORAMIQUE/INCLINAISON en cas de transport.

IMPORTANT : veillez à DÉBLOQUER ces verrous avant d’allumer le projecteur !

12. VENTILATEURS DE REFROIDISSEMENT : au cours de son fonctionnement, le projecteur produit

beaucoup de chaleur qu’il faut dissiper. La chaleur produite par le projecteur doit être dissipée par les

ventilateurs internes de la manière la plus efficace. Ainsi, il est très important de ne pas couvrir les

orifices de ventilation car cela pourrait entraîner une surchauffe.

FRANÇAIS

GUIDE D’UTILISATION

BRITEQ

®

23/107 BEAM WIZARD5x5-RGBW

SUSPENDRE L’APPAREIL

Important : L’installation ne doit être effectuée que par un personnel qualifié. Une mauvaise

installation peut entraîner des blessures et/ou des dommages graves. La suspension de l’appareil

exige une grande expérience ! Les limites de charge de fonctionnement doivent être respectées, des

matériels d’installation certifiés doivent être utilisés, l’appareil installé doit être inspecté

régulièrement pour vérifier les conditions de sécurité.

Assurez-vous qu’aucune personne étrangère ne se trouve dans la

zone en dessous de l’emplacement d’installation durant le

montage, le démontage et l’entretien.

Fixez l’appareil dans un endroit bien aéré, loin de tout matériau

et/ou liquide inflammable. L’appareil doit être fixé à au moins

50 cm des murs environnants.

L’appareil doit être installé hors de portée des personnes, loin des

passages et des endroits où des personnes peuvent aller et venir,

ou s’asseoir.

Avant de lever l’appareil, assurez-vous que le point de suspension

peut supporter une charge d’au moins 10 fois le poids de

l’appareil.

Lors de l’installation de l’appareil, utilisez toujours un câble de

sécurité certifié qui peut supporter 12 fois le poids de l’appareil. Ce

support de suspension de sécurité secondaire doit être installé de

manière à ce qu’aucune partie de l’installation ne puisse tomber

de plus de 20 cm si le support principal lâche.

L’appareil doit être bien fixé, un montage balançant est dangereux

et ne doit pas être envisagé !

Ne couvrez pas les ouvertures de ventilation, cela pourrait

entraîner une surchauffe.

L’opérateur doit s’assurer que la sécurité relative à l’installation et

les conditions techniques sont approuvées par un expert avant

d’utiliser l’appareil pour la première fois. Les installations doivent

être inspectées chaque année par une personne qualifiée pour

être sûr que la sécurité est toujours optimale.

FRANÇAIS

GUIDE D’UTILISATION

BRITEQ

®

24/107 BEAM WIZARD5x5-RGBW

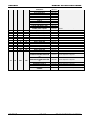

MENU DE CONFIGURATION

Le menu de configuration vous permet de configurer entièrement le projecteur. Tous les paramètres sont

mémorisés même lorsque l’appareil est débranché du secteur.

FRANÇAIS

GUIDE D’UTILISATION

BRITEQ

®

25/107 BEAM WIZARD5x5-RGBW

Instructions générales pour la configuration.

Le menu des RÉGLAGES se développent sur trois niveaux logiques structurés, voir la structure de menu à

la page précédente.

Appuyez sur la touche [MENU] pour accéder au menu des RÉGLAGES. (appuyez environ 3 s si la

fonction de verrouillage [LOCK] du menu est active).

Appuyez sur les touches ▲/▼/◄/► pour parcourir les différentes fonctions du menu des réglages jusqu’à

ce que l’entrée de votre choix s’affiche.

Appuyez sur la touche [ENTER] pour accéder à la fonction et modifier ses paramètres.

Utilisez les touches ▲/▼ pour modifier une valeur.

Appuyez de nouveau sur la touche [ENTER] pour confirmer.

Pour passer à un niveau de menu supérieur : appuyez sur la touche [MENU].

Pour quitter le menu des RÉGLAGES : appuyez de façon répétée sur la touche [MENU] jusqu’à revenir à

l’affichage normal.

Remarque : pour plus de convivialité, vous accéderez directement à la dernière position utilisée du menu

des RÉGLAGES.

[SET CONFIG > ADDRESS Set]

Toutes les fonctions de ce niveau concernent l’adressage de l’appareil.

[DMX-Address]

Pour régler l’adresse DMX souhaitée.

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER] : les valeurs sont à présent modifiables

Utilisez les touches ▲/▼ pour sélectionner l’adresse DMX512 souhaitée. La dernière adresse DMX

utilisée est également affichée : il sera plus facile de régler l’adresse de l’unité suivante dans la chaîne.

Une fois la bonne adresse affichée à l’écran, appuyez sur la touche [ENTER] pour confirmer.

Remarque : sur les contrôleurs compatibles RDM, cette option est aussi configurable à distance.

[IP-Address]

Permet de définir l’adresse IP du projecteur lorsqu’il est contrôlé à l’aide des ports Ethernet.

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER] : les valeurs sont à présent modifiables

Utilisez les touches ▲/▼/◄/► pour définir l’adresse IP souhaitée.

Une fois la bonne adresse affichée à l’écran, appuyez sur la touche [ENTER] pour confirmer.

Remarque : Une adresse IP dans la topologie Art-Net commence généralement par 2.x.x.x ou 10.x.x.x avec

un masque de sous-réseau de 255.0.0.0.

[IP-NetMask]

Permet de régler le masque de sous-réseau du projecteur lorsqu’il est utilisé à l’aide des ports

Ethernet.

Le masque de sous-réseau sera déjà réglé en fonction de l’adresse IP. La modification reste possible

en cas de nécessité :

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER] : les valeurs sont à présent modifiables

Utilisez les touches ▲/▼ pour sélectionner le masque de sous-réseau que vous souhaitez ; 3 options sont

disponibles :

255.000.000.000

255.255.000.000

255.255.255.000

Une fois l’option correcte affichée sur l’écran, appuyez sur la touche [ENTER] pour confirmer.

[DMX Universe]

Permet de définir quel univers DMX doit être utilisé lorsque le projecteur est contrôlé à l’aide des

ports Ethernet.

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER] : les valeurs sont à présent modifiables

Utilisez les touches ▲/▼ pour définir l’univers DMX souhaité (000 à 255).

Une fois l’univers DMX correct affiché sur l’écran, appuyez sur la touche [ENTER] pour confirmer.

FRANÇAIS

GUIDE D’UTILISATION

BRITEQ

®

26/107 BEAM WIZARD5x5-RGBW

[IP Protocol]

Permet de sélectionner le protocole Ethernet que vous souhaitez utiliser pour la communication.

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER] : les valeurs sont à présent modifiables

Utilisez les touches ▲/▼ pour définir le protocole souhaité.

Une fois le protocole correct affiché sur l’écran, appuyez sur la touche [ENTER] pour confirmer.

Remarque : seul Art-Net est actuellement disponible. Avec des futures mises à jour du micrologiciel,

d’autres protocoles seront ajoutés.

[SET CONFIG > CHAN Mode]

Pour régler le mode de canal souhaité.

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER] : les valeurs sont à présent modifiables

Utilisez les touches ▲/▼ pour sélectionner le mode souhaité :

Mode 12CH : [PAN/TILT] + RVB et blanc + stroboscope + son pour l’ensemble des 25 pixels.

Mode 18CH : identique au mode 12CH mais avec un contrôle de la bibliothèque d’effets RVB et

blanc.

Mode 110CH : contrôle total de toutes les fonctions, y compris un contrôle RVB et blanc pour chacun

des 25 pixels.

Mode 116CH : identique au mode 110CH mais avec un contrôle de la bibliothèque d’effets RVB et

blanc.

Une fois l’option correcte affichée sur l’écran, appuyez sur la touche [ENTER] pour confirmer.

[SET CONFIG > SHOW Config]

Toutes les fonctions de ce niveau concernent les shows automatiques.

[NO DMX Mode]

Permet de définir le comportement du projecteur lorsque le signal DMX est interrompu.

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER] : les valeurs sont à présent modifiables

Utilisez les touches ▲/▼ pour sélectionner le mode souhaité :

BLACKOUT : L’éclairage est éteint si aucun DMX n’est détecté.

FREEZE : le projecteur utilise le dernier signal DMX valide.

AUDIO : le projecteur démarre en mode audio.

Une fois l’option correcte affichée sur l’écran, appuyez sur la touche [ENTER] pour confirmer.

Remarque : dès qu’un signal DMX est détecté sur l’entrée, le mode « blackout », « freeze » ou « audio »

sera annulé.

[Install POS]

Permet de sélectionner la position d’installation du projecteur en mode autonome.

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER] pour commencer l’édition.

Utilisez les touches ▼/▲ pour sélectionner l’une des positions d’installation disponibles :

[Floor 180°] : le projecteur est placé au sol. Les mouvements de [PAN/TILT] ne sont pas limités.

[CeilingHung] : L’appareil est fixé au plafond. Les mouvements [TILT] sont limités à ±60°.

[Stage Floor] : l’appareil est placé sur une scène, en face du public. Le projecteur est toujours

orienté vers le public, c’est à dire face à la scène. Angle de mouvement [PAN] (gauche-droite-

gauche) : 160°. Angle de mouvement [TILT] : 90° (60° au-dessus de l’horizontale ; 30° sous

l’horizontale.)

[Stage Hung] : l’appareil est placé à l’envers, sur le plafond d’une scène. Le projecteur éclaire

principalement le public qui se trouve devant la scène. Angle de mouvement [PAN] (gauche-droite-

gauche) : 160°. Angle de mouvement [TILT] : 90° (verticalement, 75° vers l’avant, 15° vers l’arrière)

Une fois que le bon mode apparaît à l’écran, appuyez sur la touche [ENTER] pour confirmer.

FRANÇAIS

GUIDE D’UTILISATION

BRITEQ

®

27/107 BEAM WIZARD5x5-RGBW

[SET CONFIG > MATRIX Set]

Toutes les fonctions de ce niveau concernent le panneau de la matrice LED 5x5.

[LedBehavior]

Pour sélectionner le temps de réaction du projecteur.

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER] : les valeurs sont à présent modifiables

Utilisez les touches ▲/▼ pour sélectionner le mode souhaité :

LED

Le projecteur suit immédiatement les instructions sans délai.

HALOGEN

Le projecteur imite le comportement d’une lampe halogène (temps de réaction

plus faible).

Une fois l’option correcte affichée sur l’écran, appuyez sur la touche [ENTER] pour confirmer.

[DIM Curve]

Pour régler la courbe de gradation du gradateur maître.

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER] : les valeurs sont à présent modifiables

Utilisez les touches ▲/▼ pour sélectionner la courbe souhaitée :

Une fois la courbe souhaitée obtenue, appuyez sur la touche [ENTER] pour l’enregistrer.

[FLOW Invert]

Permet de changer le sens de rotation des chenillards.

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER] : les valeurs sont à présent modifiables

Utilisez les touches ▲/▼ pour basculer entre « ON » et « OFF ».

Appuyez sur [ENTER] pour confirmer.

[MATRIX Rot.]

Permet de sélectionner la position de la matrice LED par rapport au socle de l’unité.

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER] pour commencer l’édition.

Utilisez les touches ▼/▲ pour sélectionner l’une des positions d’installation disponibles :

[Standard] - [90°] - [180°] - [-90° (270°)]

Une fois que le bon mode apparaît à l’écran, appuyez sur la touche [ENTER] pour confirmer.

[SOUND Mode]

Permet de définir certains des réglages de la matrice LED en mode sonore.

Appuyez sur les touches ▲/▼/◄/► jusqu’à ce que la fonction souhaitée s’affiche.

Appuyez sur la touche [ENTER].

FRANÇAIS

GUIDE D’UTILISATION

BRITEQ

®