Briggs & Stratton S200X32BVP61 Manual de usuario

- Categoría

- Cortadoras de césped

- Tipo

- Manual de usuario

Este manual también es adecuado para

Supplemental Setup and Operating

Instructions and Illustrated Parts Lists for

Snapper Pro Zero-Turn Riding Mowers

Using Propane Fuel

Model Description

5900847 S200X32BVP61, 61” Zero-Turn Riding Mower w/ Propane Fuel

5405257

Revision E

TP 100-7434-E-M2-SP

Briggs & Stratton Power Products Group, LLC.

5375 N. Main Street

Munnsville, NY 13409-4003

Not for

Reproduction

ES GB

Spanish English

Table of Contents

Operator Safety .................................................. 1

Propane Mower Operating Procedures ..................1

Propane Fuel Tank Filling Procedures ...................1

Procedures for Safe Handling of Propane ..............1

Features & Controls ........................................... 2

Control Functions ....................................................2

Operation ............................................................. 4

Checks Before Starting ...........................................4

Starting the Engine .................................................4

Stopping the Rider ..................................................4

Regular Maintenance ......................................... 4

Removing the Propane Tanks ................................4

Re-installing the Propane Tanks .............................5

Initial Fill of a New Propane Tank ...........................5

Excess Flow Valve ..................................................5

Leak Testing the Fuel System ................................6

Specifications ..................................................... 7

Seguridad del Operador .................................... 9

Funciones y Controles ..................................... 10

Operación .......................................................... 12

Mantenimiento Regular .................................... 13

Especificaciones .............................................. 15

Illustrated Parts Lists ....................................... 16

Tank Mount Group ................................................16

Instrument Control Panel Group ...........................18

Hydraulic & Fuel Supply Group ............................20

Electrical Schematics ............................................22

Charging Circuit ....................................................22

Cranking Circuit ....................................................23

Ignition Grounding Circuit / Operator

Presence ...............................................................24

PTO Clutch Circuit ................................................25

NOTE: In this manual, “left” and “right” are referred to as

seen from the operating position.

This manual is intended to supplement the operator’s manual included

with your machine. There is very important safety, operational and maintenance

information in this manual. Read and understand all information in your

operator’s manual and this supplement manual before attempting to operate this

machine. Save these instructions for future reference.

Briggs & Stratton Power Products Group, LLC.

Copyright © 2010 Briggs & Stratton Corporation

Milwaukee, WI, USA. All rights reserved.

The Snapper Pro logo is a trademark of Briggs &

Stratton Corporation Milwaukee, WI, USA.

Contact Information:

Briggs & Stratton Power Products Group, LLC.

5375 N. Main St.

Munnsville, NY 13409-4003

(800) 933-6175

www.SnapperPro.com

Not for

Reproduction

1

GB

Operator Safety

Operator Safety

WARNING

Avoid serious injury or death from operating

a mower using propane fuel. Follow mower

operating procedures, propane fuel and

propane fuel tank filling producedures.

PROPANE FUEL TANK FILLING

PROCEDURES

• Apropanefueltankisacylinderdesignedto

contain a liquefied petroleum gas (propane)

under pressure that is highly flammable. Filling,

operating and servicing of this cylinder (tank)

must be conducted at an approved propane

dealer by persons properly trained and qualified in

accordance with local, state, federal and provincial

jurisdictional requirements.

• Do not overfill the propane tank. Fill at an

approved propane dealer following the procedures

and specifications on the tank.

• Anewpropanetankthathasneverbeenfilled

with propane requires special procedures to

properly purge the tank of air and fill for the first

time. Refer to the instructions on the propane

tank and fill only at an approved propane dealer

following the procedures and specifications on the

tank.

MOWER OPERATING

PROCEDURES USING PROPANE

FUEL

Background

• Ferrispropanemowersaredesignedtooperate

on a propane vapor system, which draws vapor

from the fuel tank. It is not compatible with the

typical propane fork truck system that operate on

propane liquid drawn from the fuel tank.

• Thefuelsystemisdesignedwithalefthand

thread on the fuel hose and tank connections

intended to prevent use of a liquid propane tank

(using right hand threads). The mower will NOT

function correctly with a liquid propane fuel tank.

Operation

• TurnpropaneOFFatthefueltankshut-offvalve

at the end of each day, before changing fuel tanks

and/or transporting.

• Operatethemowerononepropanetankata

time. Keep the fuel tank shut-off valve on the

opposite side tank turned off.

• CLOSEthefueltankshut-offvalveonthepropane

tank immediately if you smell raw propane. DO

NOT attempt to start engine until the problem has

been identified and repaired.

• Avoidfirehazard.Neveropenthetankvapor

(spud) valve while the tank is attached or near the

unit.

Service

• DoNOTbleedpropanefuelindoors,inan

enclosed trailer, garage or other enclosed areas.

Propane is under pressure and highly flammable.

• DoNOTalteroradjustthepropanefuelsystemin

any way.

• StorepropanefueltanksonlyinOUTSIDE

areas away from electric or gas appliances and

any possible source of spark, heat or heavy

equipment. The storage facility should be

constructed and located in compliance with local,

state, federal or provincial jursidictional safety

codes.

• UseONLYaD.O.T.ratedpropanefueltank.See

your Ferris dealer to obtain extra tanks.

• Regularlychecktheflexiblesupplyline.Make

sure that they are in good condition. Replace

damaged or leaking components.

WARNING

Propane vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns

or death.

Frostbite can result from skin / eye contact

contact with leaking propane (LP) fluid.

FLAMMABLE

GAS

2

PROCEDURES FOR SAFE

HANDLING OF PROPANE

• Ifthereisapropane(LP)gasleakageinthearea,

do not attempt to start engine.

• Toprotectyourselffromtheriskoffrostbitefrom

a potential propane (LP) fluid leak, always wear

protective clothing when working on the propane

system.

P/N: 5102666

Decal, Warning, Vapor Valve

Not for

Reproduction

2 www.SnapperPro.com

GB

CONTROL FUNCTIONS

The information below briefly describes the function of individual controls. Starting, stopping, driving, and

mowing require the combined use of several controls applied in specific sequences. To learn what combination

and sequence of controls to use for various tasks see the OPERATION section.

Ground Speed Control Levers

These levers control the ground speed of the rider.

The left lever controls the left rear drive wheel and

the right controls the right rear drive wheel.

Moving a lever forward increases the FORWARD

speed of the associated wheel, and pulling back on a

lever increases the REVERSE speed.

Note: The further a lever is moved away from the

neutral position the faster the drive wheel will turn.

See the Operation section for steering instructions.

Seat Adjustment Lever

The seat can be adjusted forward and back. Move

the lever forward, position the seat as desired, and

release the lever to lock the seat in position.

Ignition Switch

The ignition switch starts and stops the engine, it has

three positions:

OFF Stops the engine and shuts off the

electrical system.

RUN Allows the engine to run and powers

the electrical system.

START Cranks the engine for starting.

NOTE: Never leave the ignition switch in the RUN

position with the engine stopped–this drains the

battery.

Features & Controls

Features & Controls

Not for

Reproduction

3

GB

Features & Controls

PTO (Power Take Off) Switch

The PTO switch engages and disengages the mower.

Pull UP on the switch to engage the mower, and push

DOWN to disengage the mower.

Throttle Control

Moving the throttle control fully forward is FULL

throttle position. Always operate the unit at FULL

throttle when mowing.

Parking Brake

DISENGAGE Releases the parking brake.

ENGAGE Locks the parking brake.

Pull the parking brake lever back to engage the

parking brake. Move the lever fully forward to

disengage the parking brake. NOTE: To start the unit

the parking brake must be engaged.

Deck Lift Pedal, Cutting

Height Adjustment Pin &

Deck Lift Lock Lever

These control the cutting height of the mower deck.

Depress the pedal until it locks into the 5” (12,7cm)

position. Place the adjustment pin in the desired

cutting height and release the lift lock lever.

Hour Meter / Maintenance Reminder

Measures the time of the PTO being engaged. The

hour meter measures the number of hours the PTO

has been engaged. The hour meter will flash an

initial oil change indicator at 5 hours, and a lubrication

reminder every 50 hours. These reminders display

for approximately two hours and will automatically

reset themselves.

Note: The hour meter will register the passage of time

only when the PTO is engaged. The hour meter has

a self contained power source so the total hours are

always visible.

Fuel Tank Shut-Off Valve

(One valve per tank)

The fuel shut off valves are located on the front of the

propane tanks. Turn the knob CLOCKWISE to close

the fuel shut off valve. Turn the knob COUNTER-

CLOCKWISE to open the fuel shut off valve.

When operating the unit, only one fuel tank shut-off

valve should be open at a time, so that LP gas is only

drawn from one tank at a time.

The propane tanks are equipped with a excess flow

valve that will automatically close and stop the flow of

propane from the tank if the flow of propane exceeds

the specified rate.

Fuel Level Guage

Displays the fuel level in the tank.

FUEL TANK CONTROLS

Not for

Reproduction

REMOVING THE PROPANE TANKS

The propane tanks must be removed from the

machine for re-filling and for long term storage.

1. Close the the fuel shut off valve (A, Figure 1) by

turning it CLOCKWISE.

2. The fuel supply hose fittings (B) are left-handed

threads. Rotate the fuel supply hose fitting to the

right to loosen the fuel supply hose fitting.

3. Release the propane tank straps (A, Figure 2) that

secure the propane tank to the machine.

4. Lift the propane tank straight up off the machine.

4 www.SnapperPro.com

GB

Operation

WARNING

If you do not understand how a specific control

functions, or have not yet thoroughly read the

FEATURES & CONTROLS section, do so now.

Do NOT attempt to operate the tractor without

first becoming familiar with the location and

function of ALL controls.

STARTING THE ENGINE

1. Open the fuel shut off valve on one of the propane

tanks by turning the fuel shut off valve COUNTER-

CLOCKWISE. Leave the valve on the opposite

tank closed.

2. While sitting in the operator’s seat, engage the

parking brake and make sure the PTO switch is

disengaged and the ground speed control levers

are locked in the NEUTRAL position.

3. Set the engine throttle control to 1/4 throttle

position.

4. Insert the key into the ignition switch and turn it to

START.

NOTE: Allow the engine to crank for 3 seconds,

if the engine does not start, re-check to see if the

crankcase is filled to the full mark on the dipstick.

If necessary fill the crankcase to the full mark on

the dipstick. See the engine Operator’s Manual for

instructions and oil recommendations.

5. After the engine starts, allow the engine to warm

up for at least a minute before engaging the PTO

switch or driving the rider.

Warm up the engine by running it for at least a minute

before engaging the PTO switch or driving the rider.

CHECKS BEFORE STARTING

• Checkthatcrankcaseisfilledtothefullmarkon

the dipstick. See the engine Operator’s Manual for

instructions and oil recommendations.

• Makesureallnuts,bolts,screwsandpinsarein

place and tight.

• Adjusttheseatposition,andmakecertainyoucan

reach all controls from operator’s position.

• Makesurethatthepropanetanksareinstalled

correctly and secured tightly. Refer to engine

manual for fuel recommendations.

• Makesurethatonlyonefuelshut-offvalveis

OPEN. Do NOT run the machine with both fuel

shut-off valves opened at the same time.

Operation

Maintenance

6. After warming the engine, ALWAYS operate

the unit at FULL THROTTLE when mowing.

In the event of an emergency the engine can be

stopped by simply turning the ignition switch

to STOP. Use this method only in emergency

situations. For normal engine shut down follow the

procedure given in STOPPING THE RIDER.

STOPPING THE RIDER

1. Returning the ground speed control levers to the

middle position will stop tractor movement. Pivot

the levers outward and lock them in NEUTRAL.

2. Disengage the PTO by pushing down on the PTO

switch.

3. Engage the parking brake by pulling the handle up

until it locks into position.

4. Move the throttle control to 1/4 throttle position

and turn the ignition key to OFF. Remove the

key.

5. Close the fuel tank shut-off valve on the propane

tank by turning the fuel tank shut-off valve

CLOCKWISE.

Not for

Reproduction

Regular Maintenance

Figure 2. Releasing the Tank Straps

A. Propane Tank Straps

A

Figure 1. Closing the Fuel Tank Shut-Off Valve

A. Fuel Shut Off Valve

B. Fuel Supply Hose Fitting (w/ Left Hand Threads)

C. Tank Positioning Bracket

A

B

C

5

GB

RE-INSTALLING THE PROPANE

TANKS

NOTE: The propane tank should be installed on

the unit so that the fuel shut-off valve and fuel level

gauge are pointing toward the rear of the machine by

the rear bumper.

1. Position the propane tank so that the tank

positioning bracket (C, Figure 1) fits into the slots

located on either side of the center slot.

2. Connect the fuel supply hose fitting (B) to the

tank. Turn the fuel supply hose fitting to the left to

tighten the fuel supply hose fitting.

3. Tighten the propane tank straps (A, Figure 2) that

secures the propane tank to the machine.

NOTE: The length of the propane tank straps are

adjustable. If the propane tank straps do not firmly

secure the propane tank in place, unclasp the

propane tanks straps, turn the handles clockwise and

then reclaps the propane tank brackets. Continue

this process until the propane tank straps hold the

tank firmly in place. DO NOT operate the machine

with a propane tank that is not firmly secured into

place.

NOTE: Wait until you are ready to start the machine

before re-opening the fuel shut off valve (A, Figure 1).

INITIAL FILL OF A NEW PROPANE

TANK

A new propane tank that has never been filled with

propane requires special procedures to properly

purge the tank of air and fill for the first time. Refer

to the instructions on the propane tank and fill only at

an approved propane dealer following the procedures

and specifications on the tank.

EXCESS FLOW VALVE

The propane tanks on this unit are equipped with

excess flow valves which will close if the flow of

propane exceeds a specified rate.

Conditions that will cause the excess flow valves to

close are:

a) If a component of the propane system suffers

significant damage, allowing the mass escape of

propane.

b) If one propane tank is empty and the fuel shut-off

valve is not closed before opening the fuel shut-off

valve on the full tank. This causes the propane

to quickly flow from the full tank to the empty tank

until both tanks are at the same level.

Not for

Reproduction

6 www.SnapperPro.com

GB

Regular Maintenance

LEAK TESTING THE FUEL SYSTEM

This procedure should only be used when trying to

identify the location of a leak.

1. Create a mixture of 50% water and 50% liquid

dishwashing soap.

2. OPEN the fuel tank shut-off valve on the left

hand propane tanks (turn valve COUNTER-

CLOCKWISE. Leave the fuel tank shut-off valve

on the right tank closed propane tank closed.

3. Using a sponge, rag or small non-metallic brush,

apply the soap water mixture at each of the

locations circled in Figure 3.

4. Check each location shown in Figure 3 for

growing bubbles, which indicate a fuel leak.

Bubbles will look something like this:

5. CLOSE the fuel tank shut-off valve (turn fully

CLOCKWISE).

6. Tighten or replace any leaking connections.

7. Repeate steps 2 through 6 until no leaks are

detected. DO NOT use the unit if leaks cannot be

stopped.ContactyourauthorizedFerrisdealerfor

assistance.

8. Repeat steps 2 through 8, with the fuel tank shut-

off valve closed on the left propane tank and

the fuel tank shut-off valve opened on the right

propane tank.

WARNING

Gaseous vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns

or death.

• DO NOT smoke or permit ignition sources in

the area while conducting a leak test.

• Perform leak test OUTDOORS only in a well

ventilated area.

• DO NOT perform a leak test with a match or

open flame.

• DO NOT perform a leak test while the unit is

in use.

• ALWAYS perform a leak test whenever any

fuel system components are changed.

FLAMMABLE

GAS

2

9. When you are done testing the system make sure

that both fuel tank shut-off valves are CLOSED

until you are ready to use the unit again.

10. Wash off soapy residue with clean cold water and

towel dry.

11. Wait five minutes to allow all gas to evacuate the

area before starting the generator.

NOTE: The leak test must be performed in an area

that has adequate lighting in order to see if bubbles

are developing. DO NOT use a flashlight to check for

bubbles.

Figure 3. Leak Test Locations

A. Regulator and Connections

B. Propane Tank (Right Side Shown)

A

B

Not for

Reproduction

7

GB

NOTE: Specifications are correct at time of printing and are subject to change without notice.

Actual sustained equipment horsepower will likely be lower due to operating limitations and environmental factors.

ENGINE:

Briggs & Stratton**

Make Briggs & Stratton

Model 543577-0110-E1

Displacement 54.62 Cu. in (895 cc)

Electrical System 12 Volt, 20 amp. Alternator, Battery: 340

CCA

Oil Capacity 2.4 US qt. (2.25 L) w/ Filter

CHASSIS:

Rear Wheels TireSize:24x12.00-12

Inflation Pressure: 15 psi (1,03 bar)

Front Wheels TireSize:13x6.50-6

Inflation Pressure: 25 psi (1,72 bar)

TRANSMISSIONS:

HydroGear PG-3H / HGM-12E 3131

Type Pump and Wheel Motor

Hydraulic Fluid SAE 20W-50 motor oil

Speeds Forward: 0-10 MPH (0-16.09 km/h)

@ 3400 rpm Reverse: 0-5 MPH (0-8.05 km/h)

Continuous Torque 222 ft. lbs. (301 N.m.)

Output

Maximum Weight 750 lbs. (340 Kg)

on Axle

DIMENSIONS:

Overall Length 79” (201 cm)

Overall Width 62” (157 cm)

Height 68” (173 cm)

Weight (apx..) 1175 lbs. (534 kg)

Specifications

**Engine Power Rating Information

The gross power rating for individual gas engine models is labeled in accordance with SAE (Society of

Automotive Engineers) code J1940 (Small Engine Power & Torque Rating Procedure), and rating performance

has been obtained and corrected in accordance with SAE J1995 (Revision 2002-05). Torque values are derived

at 3060 RPM; horsepower values are derived at 3600 RPM. Actual gross engine power will be lower and is

affected by, among other things, ambient operating conditions and engine-to-engine variability. Given both

the wide array of products on which engines are placed and the variety of environmental issues applicable to

operating the equipment, the gas engine will not develop the rated gross power when used in a given piece

of power equipment (actual “on-site” or net power). This difference is due to a variety of factors including, but

not limited to, accessories (air cleaner, exhaust, charging, cooling, carburetor, fuel pump, etc.), application

limitations, ambient operating conditions (temperature, humidity, altitude), and engine-to-engine variability. Due

to manufacturing and capacity limitations, Briggs & Stratton may substitute an engine of higher rated power for

this Series engine.

Not for

Reproduction

8 www.SnapperPro.com

ES

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Notes / Notas

Not for

Reproduction

9

ES

Seguridad del Operador

ADVERTENCIA

Evite sufrir lesiones graves o la muerte al

operar un cortacésped con combustible

de propano. Siga los procedimientos de

operación del cortacésped, del combustible

de propano y de llenado del depósito de

combustible de propano.

PROCEDIMIENTOS DE LLENADO

DEL DEPÓSITO DE COMBUSTIBLE

DE PROPANO

• Undepósitodecombustibledepropanoes

un cilindro diseñado para contener un gas de

petróleolicuado(propano)bajopresiónquees

altamenteinflamable.Elllenado,laoperación

yelmantenimientodeestecilindro(depósito)lo

deberealizarpersonaldebidamentecapacitadoy

calificado en un distribuidor de propano aprobado

enconformidadconlosrequisitosdelajurisdicción

local, estatal, federal y provincial.

• Nolleneeldepósitodepropanoenexceso.

Abastezcacombustibleenundistribuidordepropano

aprobado siguiendo los procedimientos y las

especificacionesqueapareceneneldepósito.

• Undepósitodepropanonuevoquenuncasehaya

llenado con propano requiere procedimientos

especialesparapurgaradecuadamenteeldepósito

deaireyllenarloporprimeravez.Consultelas

instruccionesqueapareceneneldepósitode

propano y llénelo solamente en un distribuidor de

propano aprobado, siguiendo los procedimientos y

lasespecificacionesqueapareceneneldepósito.

PROCEDIMIENTOS OPERATIVOS

DEL CORTACÉSPED AL USAR

COMBUSTIBLE DE PROPANO

Antecedentes

• LoscortacéspedesFerrisapropanoestándiseñados

para que funcionen en un sistema a vapor de

propano,elqueextraevapordeldepósitode

combustible. No es compatible con el sistema de

propano típico de un elevador de horquilla que

funciona con propano líquido que se extrae del

depósitodecombustible.

• Elsistemadecombustibleestádiseñadoconuna

roscaizquierdaenlasconexionesdelamangueray

deldepósitodecombustibleparaevitarelusodeun

depósitodepropanolíquido(conroscasderechas).

ElcortacéspedNOfuncionarácorrectamenteconun

depósitodecombustibledepropanolíquido.

Operación

• APAGUEelsuministrodepropanoenlaválvulade

cortedeldepósitodecombustiblealfinaldecada

día,antesdecambiardepósitosdecombustibleode

transportarlo.

• Opereelcortacéspedconundepósitodepropano

alavez.Mantengacerradalaválvuladecortedel

depósitodecombustiblequeseencuentraenellado

opuesto del mismo.

• CIERREinmediatamentelaválvuladecortedel

depósitodecombustiblequeseencuentraenel

mismo si siente olor a propano. NO intente arrancar

el motor hasta que se haya identificado y reparado

el problema.

• Eviteriesgosdeincendio.Nuncaabralaválvula

(deconexión)devapordeltanquecuandoeltanque

esté sujeto a la unidad o cerca de la misma.

Mantenimiento

• NOpurguecombustibledepropanoeninteriores,

enunremolquecerrado,ungarajeuotrasáreas

cerradas.Elpropanoseencuentrabajopresiónyes

altamente inflamable.

• NOaltereniajusteelsistemadecombustiblede

propano de ninguna manera.

• Almacenedepósitosdecombustibledepropano

solamenteenáreasEXTERIORESlejosde

artefactos eléctricos o a gas, y de cualquier posible

fuente de chispas, calor o equipo pesado. El recinto

de almacenamiento debe estar construido y ubicado

enconformidadconloscódigosdeseguridaddela

jurisdicciónlocal,estatal,federaloprovincial.

• UseSÓLOundepósitodecombustibledepropano

ADVERTENCIA

Los vapores de propano son

extremadamente inflamables y explosivos.

El fuego o una explosión puede causar

quemaduras graves o la muerte.

Se puede producir congelación debido al

contacto con la piel o los ojos con líquido

de propano que se fugue.

FLAMMABLE

GAS

2

PROCEDIMIENTOS DE

MANIPULACIÓN SEGURA DEL

PROPANO

• Siexisteunafugadegaspropanoenelárea,no

intente arrancar el motor.

• Paraprotegersedelriesgodecongelacióndebido

a una potencial fuga de líquido de propano, use

siemprevestimentadeprotecciónaltrabajarenel

sistema de propano.

certificado por el Departamento de Transportes de

EE.UU. Consulte con su distribuidor Ferris para

obtenerdepósitosadicionales.

• Reviseregularmentelatuberíadesuministroflexible.

Asegúrese de que esté en buenas condiciones.

Reemplace los componentes dañados o que

presenten fugas.

Seguridad del Operador

P/N: 5102666

Decal, Warning, Vapor Valve

Not for

Reproduction

10 www.SnapperPro.com

ES

Funciones y Controles

FUNCIONES DE CONTROL

La siguiente información describe brevemente la función de cada uno de los controles. Arrancar, detenerse,

conducir y podar el césped requieren del uso combinado de varios controles que se aplican en secuencias

específicas. Para aprender qué combinaciones y qué secuencia de controles deben usarse para diversas

labores, sírvase leer la sección de OPERACIÓN.

Palancas de velocidad de avance

Estas palancas controlan la velocidad de avance del

montable.Lapalancaizquierdacontrolalaruedade

traccióntraseraizquierdayladerechacontrolala

ruedadetraccióntraseraderecha.

Mover la palanca hacia adelante aumenta la

velocidad HACIA ADELANTE de la llanta asociada

yjalarlahaciaatrásaumentalavelocidaden

REVERSA.

Nota: Entre más se aleje una palanca de la posición

de neutral, más rápido girará la rueda de tracción.

Vea la sección de Operar el montable de giro cero

para obtener las instrucciones de direccionamiento.

Palanca de ajuste del asiento

El asiento puede ajustarse hacia adelante y hacia

atrás.Muevalapalancahaciaadelante,posicioneel

asiento según desee y suéltela para fijar el asiento en

esaposición.

Interruptor de encendido

El interruptor de encendido arranca y detiene el motor

y tiene tres posiciones:

OFF (apagado) Detiene el motor y corta el

sistema eléctrico.

RUN (activo) Permite que el motor corra y

suministra energía al sistema

eléctrico.

START (arrancar) Da marcha para que

arranque el motor.

NOTA: No deje nunca el interruptor de encendido en la

posición de RUN con el motor detenido ya que esto drena

la batería.

Funciones y Controles

Not for

Reproduction

11

ES

Funciones y Controles

Interruptor PTO (eliminador de

energía)

El interruptor PTO activa y desactiva la podadora.

Jale el interruptor hacia ARRIBA para activarlo y

empújelo hacia ABAJO para desactivarlo.

Control de aceleración

El acelerador controla la velocidad del motor. Mueva

el acelerador hacia adelante para aumentar la

velocidaddelmotoryhaciaatrásparabajarla.Opere

siempre con el acelerador en FULL.

Freno de mano

QUITAR Con eso se quita el freno de mano.

ACCIONAR Con eso se fija el freno de mano.

Jale la palanca del freno de mano para accionar el

mismo y mueva la palanca completamente hacia

adelante para quitarlo. NOTA: Para arrancar la

unidad, el freno de mano debe estar accionado.

Pedal elevador de la cubierta,

Pasador de ajuste de la altura

de corte y Palanca de bloqueo

del elevador de la cubierta

Éstos controlan la altura de corte de la cubierta de la

podadora. Presione el pedal hasta que quede fijo en

laposiciónde5”(12,7cm).Coloqueelpasadorde

ajuste a la altura de corte deseada y luego suelte la

palanca de bloqueo del elevador.

Medidor de horas

Mide el tiempo que el PTO lleva activado.

Válvula de corte del depósito de

combustible

(una válvula por depósito)

Lasválvulasdecortedecombustibleseubicanen

lapartedelanteradelosdepósitosdecombustible.

Gire la perilla EN EL SENTIDO DE LAS AGUJAS

DELRELOJparacerrarlaválvuladecorte

de combustible. Gire la perilla EN SENTIDO

CONTRARIO AL DE LAS AGUJAS DEL RELOJ para

abrirlaválvuladecortedecombustible.

Aloperarlaunidad,sólosedebeabrirunaválvulade

cortedeldepósitodecombustiblealavez,porloque

elgasdepetróleolicuadosóloseextraedesdeun

depósitoalavez.

Lostanquesdepropanoestánequipadoscon

unaválvuladeexcesodeflujoquesecierre

automáticamenteydetenerelflujodepropanodela

cisterna si el flujo de propano es superior a la tasa

especificada.

Medidor de combustible

Muestra el nivel de combustible en el tanque.

CONTROLES DEL DEPÓSITO DE

COMBUSTIBLE

Not for

Reproduction

12 www.SnapperPro.com

ES

Operación

RETIRO DE LOS DEPÓSITOS DE

PROPANO

Losdepósitosdepropanosedebenretirardela

máquinaparallenarlosyduranteunalmacenamiento

prolongado.

1. Cierrelaválvuladecortedecombustible(A,

Figura1)girándolaENELSENTIDODELAS

AGUJAS DEL RELOJ.

2. Los accesorios de la manguera de suministro

decombustible(B)tienenroscasizquierdas.

Gire el accesorio de la manguera de suministro

de combustible hacia la derecha para soltar

el accesorio de la manguera de suministro de

combustible.

3. Sueltelasbandasdeldepósitodepropano(A,

Figura2)quefijaneldepósitodepropanoala

máquina.

4. Levanteeldepósitodepropanodemanerarecta

delamáquina.

Mantenimiento

ADVERTENCIA

Si usted no entiende cómo funciona un control

específico, o no ha leído con detenimiento la

sección de FUNCIONES Y CONTROL, hágalo

ahora.

NO intente operar el montable sin antes

familiarizarse con la ubicación y la función de

CADA UNO de los controles.

ARRANCAR EL MOTOR

1. Sólosedebeabrirunaválvuladecortedel

depósitodecombustiblealavez.Girelaperilla

EN SENTIDO CONTRARIO AL DE LAS AGUJAS

DELRELOJparaabrirlaválvuladecortede

combustible.

2. Estando sentado en el asiento del operador,

accione el freno de mano y asegúrese de que

el interruptor PTO esté desactivado y que las

manivelas de control de movimiento estén fijas en

posicióndeNEUTRAL.

3. Coloque el control de la mariposa del motor en la

posición 1/4 de marcha.

4. Introduzcalallaveenelinterruptordeencendido

y gírela a START.

NOTA: Permita que el motor se encienda durante 3

segundos. Si no arranca el motor, vuelva a revisar

para ver si el cárter está lleno hasta la marca Full

(Lleno) en la varilla para medición del nivel. Si fuese

necesario, llene el cárter hasta la marca de Full en la

varilla para medición del nivel. Consulte el manual

del operador del motor para obtener instrucciones y

recomendaciones sobre el aceite.

REVISIONES ANTES DE

ARRANCAR

• Revisequeelaceitedelcárterestéenlamarca

de lleno de la varilla de nivel de aceite. Vea el

Manual del operador del motor para obtener

instrucciones y recomendaciones.

• Asegúresedequelastuercas,pernos,tornillosy

pasadores estén en su lugar y apretados.

• Ajustelaposicióndelasientoyasegúresede

poderalcanzartodosloscontrolesdesdeel

puesto del operador.

• Asegúresedequelosdepósitosdepropano

estén correctamente instalados y bien cerrados.

Consulte el manual del motor para conocer las

recomendaciones de combustible.

• AsegúresedequesóloseABRAunaválvula

de corte de combustible. NO haga funcionar

lamáquinaconambasválvulasdecortede

combustibleabiertasalavez.

Operación

5. Después de arrancar el motor, permitir que el

motor se caliente durante al menos un minuto

antesdeiniciarlatomadefuerzaocambiarla

conduccióndeljinete.

Caliente el motor dejándolo correr al menos un

minuto antes de activar el interruptor PTO o conducir

la unidad.

6. Después de calentar el motor, opere SIEMPRE

la unidad con el acelerador en posición de

FULL mientras poda el césped.

En caso de emergencia, el motor puede detenerse

simplemente girando el interruptor de encendido

a STOP. Use este método sólo en situaciones

de emergencia. Para apagar el motor de manera

normal, siga el procedimiento dado en DETENER EL

MONTABLE.

DETENER EL MONTABLE

1. Para detener el movimiento del montable, regrese

las palancas del control de velocidad de avance a

laposiciónmedia.Girelaspalancashaciaafuera

y fíjelas en NEUTRAL.

2. Desactive el PTO empujando hacia abajo el

interruptor.

3. Accione el freno de mano jalando la manivela

hacia arriba hasta que quede fija.

4. Muevaelcontroldelamariposahastalaposición

de 1/4 de marcha y gire la llave de encendido

hastalaposiciónOFF(Apagado).Retirelallave.

5. Cierrelaválvuladecortedeldepósitode

combustiblequeseencuentraeneldepósitode

propano en un movimiento EN EL SENTIDO DE

LAS AGUJAS DEL MOTOR.

Not for

Reproduction

13

ES

Mantenimiento regular

Figura 2. Liberación de las bandas del depósito

A. Bandas del depósito de propano

A

Figura 1. Cierre de la válvula de corte del

depósito de combustible

A. Válvula de corte de combustible

B. Accesorio de la manguera de suministro de

combustible (c/ roscas izquierdas)

C. Soporte de posicionamiento del depósito

A

B

C

REINSTALACIÓN DE LOS

DEPÓSITOS DE PROPANO

NOTA: El depósito de propano se debe instalar en la

unidad para que la válvula de corte de combustible y

el indicador de nivel de combustible apunten hacia la

parte posterior de la máquina cerca del parachoques.

1. Coloqueeldepósitodepropanodemodoque

elsoportedeposicionamientodeldepósito

(C, Figura 1) encaje en las ranuras que se

encuentran a cada lado de la ranura central.

2. Conecte el accesorio de la manguera de

suministrodecombustible(B)aldepósito.Gire

el accesorio de la manguera de suministro de

combustiblehacialaizquierdaparaapretarel

accesorio de la manguera de suministro de

combustible.

3. Aprietelasbandasdeldepósitodepropano(A,

Figura2)quefijaneldepósitodepropanoala

máquina.

NOTA: El largo de las bandas del depósito de

propano es ajustable. Si las bandas del depósito

de propano no lo fijan bien en su lugar, suéltelas,

gire las manillas en el sentido de las agujas del reloj

y luego vuelva a colocar los soportes del depósito

de propano. Continúe este proceso hasta que las

bandas del depósito de propano lo fijen firmemente

en su lugar. NO opere la máquina con un depósito

de propano que no esté fijo de manera firme en

su lugar.

NOTA: Espere hasta que esté listo para arrancar la

máquina antes de volver a abrir la válvula de corte de

combustible (A, Figura 1).

LLENADO INICIAL DE UN

DEPÓSITO DE PROPANO NUEVO

Undepósitodepropanonuevoquenuncasehaya

llenado con propano requiere procedimientos

especialesparapurgaradecuadamenteeldepósito

deaireyllenarloporprimeravez.Consultelas

instruccionesqueapareceneneldepósitode

propano y llénelo solamente en un distribuidor de

propano aprobado, siguiendo los procedimientos y

lasespecificacionesqueapareceneneldepósito.

VÁLVULA DE EXCESO DE FLUJO

Lostanquesdepropanoenestaunidadestán

equipadosconválvulasdeexcesodeflujoquese

cerrarásielflujodepropanosuperaunadeterminada

tasa.

Condiciones que causa el exceso de flujo para cerrar

lasválvulasson:

a) Si un componente del sistema de propano sufre

daños importantes, permitiendo la masiva fuga de

propano.

b) Siuntanquesdepropanoestávacíoylaválvula

de cierre de combustible no se cierra antes

deabrirlaválvuladecierredecombustible

en el tanque lleno. Esto hace que el propano

rápidamenteelflujodetanquellenoalacisterna

vacíos hasta que ambos tanques se encuentran al

mismo nivel.

Not for

Reproduction

14 www.SnapperPro.com

ES

Mantenimiento regular

PRUEBA DE FUGAS DEL SISTEMA

DE COMBUSTIBLE

Esteprocedimientosólosedebeusaralintentar

identificarlaubicacióndeunafuga.

1. Creeunamezclade50%deaguay50%dejabón

lavavajillas líquido.

2. ABRAlaválvuladecortedeldepósitode

combustiblequeseencuentraalaizquierda

delosdepósitosdepropano(girelaválvulaen

sentido CONTRARIO AL DE LAS AGUJAS DEL

RELOJ.Dejecerradalaválvuladecorteenel

depósitodepropanoderecho.

3. Con una esponja, un trapo o una escobilla no

metálicapequeña,apliquelamezcladeaguacon

jabónencadaunodeloslugaresencerradosen

un círculo en la Figura 3.

4. Revise todos los lugares que se muestran en

la Figura 3 parta saber si existen burbujas que

indiquen una fuga de combustible. Las burbujas

seránsimilaresaesto:

5. CIERRElaválvuladecortedeldepósitode

combustible (gírela completamente EN EL

SENTIDO DE LAS AGUJAS DEL RELOJ).

6. Apriete o reemplace todas las conexiones que

presenten fugas.

7. Repita los pasos 2 al 6 hasta que no se detecten

fugas. NO use la unidad si no se pueden detener

las fugas. Comuníquese con su distribuidor Ferris

ADVERTENCIA

Los vapores gaseosos son

extremadamente inflamables y explosivos.

El fuego o una explosión puede causar

quemaduras graves o la muerte.

• NO fume ni permita fuentes de encendido en

el área mientras realice una prueba de fugas.

• Realice pruebas de fugas en EXTERIORES

sólo en un área ventilada.

• NO realice una prueba de fugas con un

fósforo o una llama abierta.

• NO realice una prueba de fugas mientras esté

en uso la unidad.

• Realice SIEMPRE una prueba de fugas

cuando se cambie cualquier componente del

sistema de combustible.

FLAMMABLE

GAS

2

autorizadoparaobtenerasistencia.

8. Repitalospasos2al8conlaválvuladecortedel

depósitodecombustiblecerradaeneldepósito

depropanoizquierdoyconlaválvuladecortedel

depósitodecombustibleabiertaeneldepósitode

propano derecho.

9. Cuando termine de probar el sistema, asegúrese

dequeambasválvulasdecortedeldepósitode

combustible estén CERRADAS hasta que esté

listo para usar nuevamente la unidad.

10.Limpielosresiduosdejabónconaguafríalimpia

y una toalla seca.

11. Espere cinco minutos para permitir que se

evacuetodoelgasdeláreaantesdearrancarel

generador.

NOTA: La prueba de fugas se debe realizar en un

área que tenga la iluminación adecuada para saber

si se desarrollan burbujas. NO use una linterna para

Figura 3. Lugares de prueba de fugas

A. Regulador y conexiones

B. Depósito de propano (se muestra el lado

derecho)

A

B

Not for

Reproduction

15

ES

MOTOR:

Briggs & Stratton**

Marca Briggs & Stratton

Modelo 543577-0110-E1

Carrera 54.62 pulgadas cúbicas (895 cc)

Sistema eléctrico 12 voltios, 20 amp. Alternador, batería:

340 CCA

Oil Capacity 2.4 US qt. (2.25 L) c/ filtro

CHASSIS:

Tanques de gasolina Capacidad: 56 lbs neto

Ruedas traseras Tamaño de llanta: 24 x 12.00 -12

Presióndeinflado:15psi(1,03bar)

Ruedas delanteras Tamaño de llanta: 13 x 6.50 - 6

Presióndeinflado:25psi(1,72bar)

TRANSMISIONES:

HydroGear PG-3H / HGM-12E 3131

Tipo: Bomba y motor radial

Fluido hidráulico Aceite del motor del SAE 20W-50

Velocidad Hacia adelante: 0-10 MPH (0-16.09 km/h)

@ 3400 rpm Haciaatrás:0-5MPH(0-8.05km/h)

Par de torsión continuo 222 ft. lbs. (301 N.m.)

Salida

Peso máximo 750 lbs. (340 kg)

en eje

DIMENSIONES:

Longitud total 79” (201 cm)

Anchura total 62” (157 cm)

Altura 68” (173 cm)

Peso (aprox.) 1175 lbs. (534 kg))

NOTA: Las especificaciones son correctas al momento de la impresión y están sujetas a cambios sin previo aviso.

La potencia continua real del equipo muy probablemente sea menor, debido a las limitantes de operación y a los

factores ambientales.

Especificaciones

**Información de Clasificación de Potencia del Motor

La puissance brute pour chaque Modèle de moteur à essence est indiquée conformément au code J1940

(procédure de calcul de la puissance et du couple des petits moteurs) de la SAE (Society of Automotive

Engineers) et les performances théoriques ont été obtenues et corrigées selon SAE J1995 (révision 2002-

05). Les valeurs de couple sont calculées sur la base de 3 060 tr/min et celles de puissance sur la base de

3 600 tr/min. La puissance brute réelle du moteur peut être plus faible notamment à cause des conditions

de fonctionnement et des variations d’un moteur à l’autre. Compte tenu de la grande variété de machines

sur lesquelles nos moteurs sont utilisés et du nombre de problèmes environnementaux applicables au

fonctionnement des équipements, il se peut que le moteur à essence ne développe pas sa puissance théorique

une fois qu’il est monté dans une machine particulière (puissance nette ou réelle « sur site »). Cette différence

s’explique par un grand nombre de facteurs, tels que les suivants (liste non limitative) : accessoires (filtre à air,

échappement, admission, refroidissement, carburateur, pompe à essence, etc.), limites d’utilisation, conditions

ambiantes d’utilisation (température, humidité, altitude) et variations d’un moteur à l’autre. Pour des raisons de

fabrication et de capacité limitées, Briggs & Stratton est susceptible de remplacer ce Modèle par un moteur plus

puissant.

Not for

Reproduction

16 www.SnapperPro.com

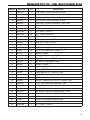

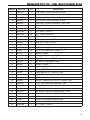

Supplemental Parts List - Tanks, Mounts & Guards Group

13

14

15

15

15

16

16

16

16

17

17

17

17

17

17

17

16

17

18

18

28

18

18

18

15

31

11

29

30

12

18

19

20

23

24

21

21

22

25

26

27

1

2

5

6

7

7

32

7

7

7

7

35

8

18

9

9

9

10

3

4

34

Not for

Reproduction

17

Supplemental Parts List - Tanks, Mounts & Guards Group

REF NO. PART NO. QTY DESCRIPTION

1 5405195D 1 WELD, MOUNT, TANK, PROPANE, RH -RED

2 5405199D 1 WELD, MOUNT, TANK, PROPANE, REAR RH -RED

3 5405202D 1 WELD, MOUNT, TANK, PROPANE, REAR LH -RED

4 5405203D 1 WELD, MOUNT, TANK, PROPANE, LH -RED

5 5405226D 1 PLATE, BRKT, REGULATOR MOUNT, PROP - RED

6 5405277 2 RUBBER,FENDERGUARD,S200XPROPANE

7 5025011X8 30 BOLT,5/16-18X1GD5YZ

8 5025013X8 2 BOLT,3/8-16X1GD5YZ

9 5025010X6 10 BOLT,1/4-20X3/4GD5YZ

10 5025011X12 2 BOLT,5/16-18X1-1/2GD5YZ

11 5025299X6 4 SCREW,1/4-20X3/4ALLENBH

12 5022665 4 BODYCLIP,1/4-20X1/2DEEP

13 5023215 1 CAPSCREW-HEXHEADM6-1.0X14MM

14 5025226 1 WASHER,M6FLATZP

15 5025391 14 NUT,1/4-20HEXNYLOCKFLANGE

16 5025154 14 WASHER, 1/4 SAE

17 5025155 32 WASHER, 5/16 SAE

18 5025392 32 NUT,5/16-18HEXNYLOCKFLANGE

19 5025394 2 NUT,3/8-16HEXNYLOCKFLANGE

20 5025156 2 WASHER, 3/8 SAE

21 5023173 5 CLAMP, HOSE, 1.000 DIA.

22 5405278A 2 BAR, RUBBER FENDER GUARD BRACKET - BLK

23 5101427 4 STRAP, BRACKET KIT, PROPANE TANK

24 5101423 1 REGULATOR, PROPANE

25 5404096 1 VALVE, LOCK OFF ASSEMBLY

26 5403765D 1 BRACKET, REGULATOR LOCKOFF, PROPANE -RED

27 5405267D 2 PLATE,TANKPOSITIONINGBRACKET,200X

28 5405227D 1 PLATE, HYDRO TANK MOUNT, PROPANE

29 5405300D 2 PLATE, MOTION CONTROL GUARD - RED

30 5405299D 4 BAR, MOUNT CONTROL GUARD BRACKET - RED

31 5101707 2 TANK, PROPANE, WORTHINGTON - NET

32 5025011X9 1 BOLT,5/16-18X11/8GD5YZ

33 5101425 1 SWITCH, OIL PRESSURE (Not illustrated)

34 5102666 2 DECAL, WARNING, VAPOR VALVE

35 5025010X8 4 BOLT,1/4-20X1GD5YZ

Not for

Reproduction

18 www.SnapperPro.com

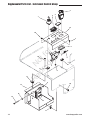

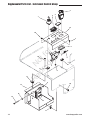

Supplemental Parts List - Instrument Control Group

3

4

5

6

7

8

8

9

10

10

10

1

2

12

13

14

15

16

17

11

11

11

11

Not for

Reproduction

19

Supplemental Parts List - Instrument Control Group

REF NO. PART NO. QTY DESCRIPTION

1 5020927 1 SWITCH, IGNITION, 6 POST

2 5022180 1 SWITCH, BLADE ENGAGEMENT

3 5022222 1 RING, SWITCH RETAINER

4 5100996 1 HOUR METER, W/ SUPRESSOR

5 5046360 1 HANDLE, THROTTLE CONTROL

6 5101073 1 CABLE, THROTTLE, 42”

7 5025179X6 2 SCREW,#10-24X3/4”ROUNDPHILLIPS

8 5025271 4 NUT,#10-24HEXNYLONLOCK

9 1709188 1 PLUG,.820X1.44HOLE,BLACKPLASTIC

10 5025299X6 4 SCREW,1/4-20X3/4ALLENBH

11 5022665 4 BODYCLIP,1/4-20X1/2DEEP

12 5405268A 1 PLATE,INSTRUMENTCONTROLPANEL,S200X

13 5405248D 1 PLATE,INSTRUMENTCONTROLSHIELD,S200X

14 5025270X16 2 SCREW,#10-24X2ROUNDPHILLIPS

15 5023499 2 WASHER, #10 SAE

16 5061763 2 SPACER,.20X.38X1.25

17 5021518 1 FUSE BLOCK

Not for

Reproduction

20 www.SnapperPro.com

Supplemental Parts List - Hydraulic & Fuel Supply Group

ENGINE

TO TANKTO TANK

REGULATOR

1

1

17

1

1

2 2 2 2

3

3

4

5 5

5

55

5

14

6

6

6

6

6

7

8 8

9

10

36

36

16

11

11

14

16

13

15

12

21

1819

20

22

23

37

24 24

25

26

27

28

29

34

30

34

31

32

33

41

35

30 30

38

5

5

39

40

Not for

Reproduction

21

Supplemental Parts List - Hydraulic & Fuel Supply Group

REF NO. PART NO. QTY DESCRIPTION

1 5022634 4 ADAPTER, HYD.

2 5023338 4 FITTING, #8 JIC - #8 O-RING, 45 DEG.

3 5023267 2 ADAPTER, 90 DEG, 9/16-3/8 BARB

4 5022920 1 FITTING, TEE, 1/2 HOSE

5 5021164 8 CLAMP, #10 HOSE, STAINLESS

6 5023268 7 CLAMP, HOSE

7 5022364 1 FITTING, BRANCH TEE

8 5100678 2 FITTING, STRAIGHT, HYD #12618

9 5101046 1 FITTING, 45 DEG 1/2 NPT MALE - 5/8 HOSE

10 5022922 1 CLAMP, #4 HOSE, STAINLESS

11 5023119 2 FITTING, 90 DEG, 5/8

12 5050860X8 1 HOSE, 3/8” PUSH-LOCK, 8.00”

13 5050860X16 1 HOSE, 3/8” PUSH-LOCK, 16.00”

14 5050860X24 2 HOSE, 3/8” PUSH-LOCK, 24.00”

15 5050861X12 1 WIRE LOOM, 5/8” ID, 12” LONG

16 5050861X21 2 WIRE LOOM, 5/8” ID, 21” LONG

17 5050933X4P5 1 HOSE,5/8,PUSH-LOCKX4.5”

18 5050933X11 1 HOSE,5/8,PUSH-LOCKX11”

19 5050933X15 1 HOSE,5/8,PUSH-LOCKX15”

20 5050933X22 1 HOSE,5/8,PUSH-LOCKX22”

21 5100384X19 1 LOOM,CONVOLUTEDSPLIT,1”IDX19”

22 5101423 1 REGULATOR, PROPANE

23 5404096 1 VALVE, LOCK OFF ASSEMBLY

24 5101429 2 COUPLING, PROPANE TANK

25 5101430 1 RELIEF VALVE, PROPANE

26 5101431 1 HOSE,RHFUELSUPPLYASMX36,PROPANE

27 5101432 1 HOSE,LHFUELSUPPLYASMX16.62PROPANE

28 5101433 1 HOSE,LOWPRESFUELX33.25,PROPANE

29 5404026 1 HOSE,1/4IDVACHOSEX29,PROPANE

30 5101436 3 FITTING,TEE,1/4NPTMX45ELBOW,BRASS

31 5101437 1 FITTING, 1/4 NPTM STRAIGHT, BRASS

32 5101439 1 FITTING,1/4HOSEBARBX1/8NPT,BRASS

33 5101440 2 FITTING,3/8HOSEBARBX1/4NPT,BRASS

34 5102029 2 FITTING,45STREETELBOW,CZ

35 5101452 2 FITTING,1/4NPTX45,STREETELBOWBRASS

36 5020835 2 CLAMP,HOSE,EXTERNAL

37 5101570 1 FITTING, 1/4 STREET ELBOW PLATED

38 5101569 2 FITTING,3/8NPTX1/2HOSEBARB,90ELBOW

39 5100384X29 1 LOOM,CONVOLUTEDSPLIT,1’IDX29IN

40 5101571 1 FITTING, 1/4 NPT TEE, PLATED

41 5101572 1 FITTING, 1/4 NPT STREET TEE, PLATED

Not for

Reproduction

22 www.SnapperPro.com

Supplemental Parts List - Electrical Schematic - Charging Circuit

RELAY

START

WHITE 4"

BLUE 33"

SPLICE

SPLICE #5

GRN

21850

2

2

18

1

ORN

O/W

GRY

20906

GRN

ORANGE/GREEN 16"

21850

O/BK

BLK

GRY

O/W

O/BKGRY

VIO

RED

RED

VIO

20906

SPLICE

STARTER

GRY

20906

YEL

RED

BLK

VIO

BLU

GRY

BLK

20906

87A

30

87

86

85

22992

22992

2

0

087

20087

GRY

BLK

2

0

0

9

0

O/BK

GRAY 15"

O/BK

21548

SPLICE

SPLICE

SPLICE

SPLICE

SPLICE

20090

2X ORANGE/GREEN 16"

SPLICE #7

WHT

O/W

VIO

BRAKE

WHITE 39"

SPLICE #4

ORANGE / WHITE 8"

VIOLET 8"

BLACK 50"

W

H

I

T

E

5

"

SPLICE #3

BLUE 8"

SPLICE #6

BLUE 8"

ORANGE 58"

GREEN 65"

BLUE 21"

ORANGE / GREEN 38"

21548

GRAY 4"

RED 9" (12 GA)

RED 54" (12GA)

VIOLET 20"

YELLOW 18"

BLACK 20"

YELLOW 44"

GRAY 54"

BLACK 21"

RELAY

SHUT DOWN

GRAY 10"

SWITCH

ORANGE /

SWITCH

NEUTRAL

LEFT HAND

ENGINE

SWITCH

SEAT

SWITCH

CLUTCH

BLACK 8"

BK

GRAY 10"

VIOLET 9"

PTO

PARKING

MODULE

DELAY

TIME

SPLICE

SWITCH

GREEN 4"

YELLOW 27"

KEY

5020907

5021850

5020907

5020906

5020907

5020906

5023133

SPLICE #1

WHITE 16"

ORANGE / WHITE 45"

5022992

TO

5020914

5021517

5023133

BLACK 19"

BLACK 17"

5022992

5020087

GROUND

5020907

ORANGE / BLACK 68"

VIOLET 5"

BLACK 21"

BLACK 19"

SPLICE #2

ORANGE / BLACK 13"

5020906

BLU

5020087

5020907

5021850

AUXILIARY

HEADLIGHT /

5020907

5023494

5

020914

5021092

5020907

5020090

5020906

5020907

502

1548

5020907

5021548

HARNESS

SWITCH

AUXILARY

HEADLIGHT /

5020907

5020910

5020907

5022181

HOURMETER

5020090

SOLENOID

5020907

5021850

STARTER

SWITCH

ORANGE / WHITE 10"

SPLICE #8

BLACK 8"

NEUTRAL

RIGHT HAND

WHT

O/W

O/G

VIOLET 33"

86

87

85

87A

30

BLUE

O/G

ORN

O/G

YEL

YEL

O/G

VIO

TO FUSE

BLOCK

SEAT

SWITCH

5022198

NC

NC

LH NEUTRAL

SWITCH

5021451

NO

TIME DELAY MODULE

SCHEMATIC

PARKING BRAKE

SWITCH

5022182

NC

NO

HOURMETER

5100996

RH NEUTRAL

SWITCH

5021451

NO

12

5

6

34

7

8

TO FUSE BLOCK

HARNESS

PTO

SWITCH

5022180

COMNONC

RELAY

5021766

85

86

30

87A

87

85

86

30

87A

87

PTO CLUTCH

5100084

AUXILARY

SWITCH

AUXILARY

CONNECTOR

M

L

G

B

S

IGNITION

SWITCH

5020927

A

1 2

34

5

BATTERY

NEGATIVE BATTERY CABLE

5044014

POSITIVE BATTERY CABLE

5021405

43

8

7

21

6

5

20A

20A

20A

20A

FUSE BLOCK HARNESS

5401328

RED

RED

VIOLET

VIOLET

GRAY

GRAY

ORANGE/BLACK

ORANGE/BLACK

TO ENGINE

BLOCK

STARTER

MOTOR

GREEN

ORANGE

ORANGE / GREEN

ORANGE /

GREEN

ORANGE /

GREEN

BLUE

BLUE

ORANGE / BLACK

YELLOW

YELLOW

BLACK

BLACK

BLACK

BLACK

BLACK

WHITE

YELLOW

VIOLET

VIOLET

VIOLET

ORANGE / WHITE

BLUE

ORANGE / WHITE

ORANGE / WHITE

BLACK

RELAY

5021766

TO ENGINE

HARNESS

1

5

4

3

2

1

456

3 2

BLUE

YELLOW

WHITE

WHITE

GREEN

BLACK

BLACK

BLACK

BLACK

GRAY

RED

RED

VIOLET

GRAY

GRAY

VIOLET

ORANGE / WHITE

ORANGE / BLACK

BLACK

GRAY

GRAY

Main Harness Part No:

5402942

IGNITION SWITCH

POSITION CIRCUIT MAKE

1. OFF G & M & A

2. RUN B & L & A

3. STARTB & L & S

1

3

5

7

2

4

6

8

IGNITION

BROWN

BLACK

RED

32 HP BRIGGS & STRATTON ENGINE (PROPANE READY)

GROUND

VOLTAGE REGULATOR

1

3

5

2

4

6

YELLOWYELLOW

TO ENGINE

HARNESS

TO MAIN

HARNESS

TO MAIN

HARNESS

TO JUMPER

HARNESS

TO JUMPER

HARNESS

TO PROPANE

LOCK OFF VALVE

TO STARTER

SOLENOID

1

3

5

7

2

4

6

8

BLACK

VIOLET

WHITE

ORG / WHT

BLACK BLACK

JUMPER HARNESS

5405276

12

OIL

PRESSURE

SWITCH

NO

NC

COMMON

YELLOW

YELLOW

YELLOW

ORG / BLK

BLACK

BLACK

12

PROPANE

SOLENOID

PROPANE LOCK

OFF VALVE

5404096

Not for

Reproduction

23

Supplemental Parts List - Electrical Schematic - Cranking Circuit

RELAY

START

WHITE 4"

BLUE 33"

SPLICE

SPLICE #5

GRN

21850

2

2

1

8

1

ORN

O/W

GRY

20906

GRN

ORANGE/GREEN 16"

21850

O/BK

BLK

GRY

O/W

O/BKGRY

VIO

RED

RED

VIO

20906

SPLICE

STARTER

GRY

20906

YEL

RED

BLK

VIO

BLU

GRY

BLK

20906

87A

30

87

86

85

22992

22992

2

0

0

87

20087

GRY

BLK

2

0

0

9

0

O/BK

GRAY 15"

O/BK

21548

SPLICE

SPLICE

SPLICE

SPLICE

SPLICE

20090

2X ORANGE/GREEN 16"

SPLICE #7

WHT

O/W

VIO

BRAKE

WHITE 39"

SPLICE #4

ORANGE / WHITE 8"

VIOLET 8"

BLACK 50"

W

H

I

T

E

5

"

SPLICE #3

BLUE 8"

SPLICE #6

BLUE 8"

ORANGE 58"

GREEN 65"

BLUE 21"

ORANGE / GREEN 38"

21548

GRAY 4"

RED 9" (12 GA)

RED 54" (12GA)

VIOLET 20"

YELLOW 18"

BLACK 20"

YELLOW 44"

GRAY 54"

BLACK 21"

RELAY

SHUT DOWN

GRAY 10"

SWITCH

ORANGE /

SWITCH

NEUTRAL

LEFT HAND

ENGINE

SWITCH

SEAT

SWITCH

CLUTCH

BLACK 8"

BK

GRAY 10"

VIOLET 9"

PTO

PARKING

MODULE

DELAY

TIME

SPLICE

SWITCH

GREEN 4"

YELLOW 27"

KEY

5020907

5021850

5020907

5020906

5020907

5020906

5023133

SPLICE #1

WHITE 16"

ORANGE / WHITE 45"

5022992

TO

5020914

5021517

5023133

BLACK 19"

BLACK 17"

5022992

5020087

GROUND

5020907

ORANGE / BLACK 68"

VIOLET 5"

BLACK 21"

BLACK 19"

SPLICE #2

ORANGE / BLACK 13"

5020906

BLU

5020087

5020907

5021850

AUXILIARY

HEADLIGHT /

5020907

5023494

5020914

5021092

5020907

5020090

5020906

5020907

5021

548

5020907

5021548

HARNESS

SWITCH

AUXILARY

HEADLIGHT /

5020907

5020910

5020907

5022181

HOURMETER

5020090

SOLENOID

5020907

5021850

STARTER

SWITCH

ORANGE / WHITE 10"

SPLICE #8

BLACK 8"

NEUTRAL

RIGHT HAND

WHT

O/W

O/G

VIOLET 33"

86

87

85

87A

30

BLUE

O/G

ORN

O/G

YEL

YEL

O/G

VIO

TO FUSE

BLOCK

SEAT

SWITCH

5022198

NC

NC

LH NEUTRAL

SWITCH

5021451

NO

TIME DELAY MODULE

SCHEMATIC

PARKING BRAKE

SWITCH

5022182

NC

NO

HOURMETER

5100996

RH NEUTRAL

SWITCH

5021451

NO

12

5

6

34

7

8

TO FUSE BLOCK

HARNESS

PTO

SWITCH

5022180

COMNONC

RELAY

5021766

85

86

30

87A

87

85

86

30

87A

87

PTO CLUTCH

5100084

AUXILARY

SWITCH

AUXILARY

CONNECTOR

M

L

G

B

S

IGNITION

SWITCH

5020927

A

1 2

34

5

BATTERY

NEGATIVE BATTERY CABLE

5044014

POSITIVE BATTERY CABLE

5021405

43

8

7

21

6

5

20A

20A

20A

20A

FUSE BLOCK HARNESS

5401328

RED

RED

VIOLET

VIOLET

GRAY

GRAY

ORANGE/BLACK

ORANGE/BLACK

TO ENGINE

BLOCK

GREEN

ORANGE

ORANGE / GREEN

ORANGE /

GREEN

ORANGE /

GREEN

BLUE

BLUE

ORANGE / BLACK

YELLOW

YELLOW

BLACK

BLACK

BLACK

BLACK

BLACK

WHITE

YELLOW

VIOLET

VIOLET

VIOLET

ORANGE / WHITE

BLUE

ORANGE / WHITE

ORANGE / WHITE

BLACK

RELAY

5021766

TO ENGINE

HARNESS

1

5

4

3

2

1

456

3 2

BLUE

YELLOW

WHITE

WHITE

GREEN

BLACK

BLACK

BLACK

BLACK

GRAY

RED

RED

VIOLET

GRAY

GRAY

VIOLET

ORANGE / WHITE

ORANGE / BLACK

BLACK

GRAY

GRAY

Main Harness Part No:

5402942

IGNITION SWITCH

POSITION CIRCUIT MAKE

1. OFF G & M & A

2. RUN B & L & A

3. STARTB & L & S

STARTER

MOTOR

1

3

5

7

2

4

6

8

IGNITION

BROWN

BLACK

RED

32 HP BRIGGS & STRATTON ENGINE (PROPANE READY)

GROUND

VOLTAGE REGULATOR

1

3

5

2

4

6

YELLOWYELLOW

TO ENGINE

HARNESS

TO MAIN

HARNESS

TO MAIN

HARNESS

TO JUMPER

HARNESS

TO JUMPER

HARNESS

TO PROPANE

LOCK OFF VALVE

TO STARTER

SOLENOID

1

3

5

7

2

4

6

8

BLACK

VIOLET

WHITE

ORG / WHT

BLACK BLACK

JUMPER HARNESS

5405276

12

OIL

PRESSURE

SWITCH

NO

NC

COMMON

YELLOW

YELLOW

YELLOW

ORG / BLK

BLACK

BLACK

12

PROPANE

SOLENOID

PROPANE LOCK

OFF VALVE

5404096

Not for

Reproduction

24 www.SnapperPro.com

RELAY

START

WHITE 4"

BLUE 33"

SPLICE

SPLICE #5

GRN

21850

2

2

1

8

1

ORN

O/W

GRY

20906

GRN

ORANGE/GREEN 16"

21850

O/BK

BLK

GRY

O/W

O/BKGRY

VIO

RED

RED

VIO

20906

SPLICE

STARTER

GRY

20906

YEL

RED

BLK

VIO

BLU

GRY

BLK

20906

87A

30

87

86

85

22992

22992

2

0

0

87

20087

GRY

BLK

2

0

0

9

0

O/BK

GRAY 15"

O/BK

21548

SPLICE

SPLICE

SPLICE

SPLICE

SPLICE

20090

2X ORANGE/GREEN 16"

SPLICE #7

WHT

O/W

VIO

BRAKE

WHITE 39"

SPLICE #4

ORANGE / WHITE 8"

VIOLET 8"

BLACK 50"

W

H

I

T

E

5

"

SPLICE #3

BLUE 8"

SPLICE #6

BLUE 8"

ORANGE 58"

GREEN 65"

BLUE 21"

ORANGE / GREEN 38"

21548

GRAY 4"

RED 9" (12 GA)

RED 54" (12GA)

VIOLET 20"

YELLOW 18"

BLACK 20"

YELLOW 44"

GRAY 54"

BLACK 21"

RELAY

SHUT DOWN

GRAY 10"

SWITCH

ORANGE /

SWITCH

NEUTRAL

LEFT HAND

ENGINE

SWITCH

SEAT

SWITCH

CLUTCH

BLACK 8"

BK

GRAY 10"

VIOLET 9"

PTO

PARKING

MODULE

DELAY

TIME

SPLICE

SWITCH

GREEN 4"

YELLOW 27"

KEY

5020907

5021850

5020907

5020906

5020907

5020906

5023133

SPLICE #1

WHITE 16"

ORANGE / WHITE 45"

5022992

TO

5020914

5021517

5023133

BLACK 19"

BLACK 17"

5022992

5020087

GROUND

5020907

ORANGE / BLACK 68"

VIOLET 5"

BLACK 21"

BLACK 19"

SPLICE #2

ORANGE / BLACK 13"

5020906

BLU

5020087

5020907

5021850

AUXILIARY

HEADLIGHT /

5020907

5023494

5020914

5021092

5020907

5020090

5020906

5020907

5021548

5020907

502

1548

HARNESS

SWITCH

AUXILARY

HEADLIGHT /

5020907

5020910

5020907

5022181

HOURMETER

5020090

SOLENOID

5020907

5021850

STARTER

SWITCH

ORANGE / WHITE 10"

SPLICE #8

BLACK 8"

NEUTRAL

RIGHT HAND

WHT

O/W

O/G

VIOLET 33"

86

87

85

87A

30

BLUE

O/G

ORN

O/G

YEL

YEL

O/G

VIO

TO FUSE

BLOCK

SEAT

SWITCH

5022198

NC

NC

LH NEUTRAL

SWITCH

5021451

NO

TIME DELAY MODULE

SCHEMATIC

PARKING BRAKE

SWITCH

5022182

NC

NO

HOURMETER

5100996

RH NEUTRAL

SWITCH

5021451

NO

12

5

6

34

7

8

TO FUSE BLOCK

HARNESS

PTO

SWITCH

5022180

COMNONC

RELAY

5021766

85

86

30

87A

87

85

86

30

87A

87

PTO CLUTCH

5100084

AUXILARY

SWITCH

AUXILARY

CONNECTOR

M

L

G

B

S

IGNITION

SWITCH

5020927

A

1 2

34

5

BATTERY

NEGATIVE BATTERY CABLE

5044014

POSITIVE BATTERY CABLE

5021405

43

8

7

21

6

5

20A

20A

20A

20A

FUSE BLOCK HARNESS

5401328

RED

RED

VIOLET

VIOLET

GRAY

GRAY

ORANGE/BLACK

ORANGE/BLACK

TO ENGINE

BLOCK

GREEN

ORANGE

ORANGE / GREEN

ORANGE /

GREEN

ORANGE /

GREEN

BLUE

BLUE

ORANGE / BLACK

YELLOW

YELLOW

BLACK

BLACK

BLACK

BLACK

BLACK

WHITE

YELLOW

VIOLET

VIOLET

VIOLET

ORANGE / WHITE

BLUE

ORANGE / WHITE

ORANGE / WHITE

BLACK

RELAY

5021766

TO ENGINE

HARNESS

1

5

4

3

2

1

456

3 2

BLUE

YELLOW

WHITE

WHITE

GREEN

BLACK

BLACK

BLACK

BLACK

GRAY

RED

RED

VIOLET

GRAY

GRAY

VIOLET

ORANGE / WHITE

ORANGE / BLACK

BLACK

GRAY

GRAY

Main Harness Part No:

5402942

IGNITION SWITCH

POSITION CIRCUIT MAKE

1. OFF G & M & A

2. RUN B & L & A

3. STARTB & L & S

STARTER

MOTOR

1

3

5

7

2

4

6

8

IGNITION

BROWN

BLACK

RED

32 HP BRIGGS & STRATTON ENGINE (PROPANE READY)

GROUND

VOLTAGE REGULATOR

1

3

5

2

4

6

YELLOWYELLOW

TO ENGINE

HARNESS

TO MAIN

HARNESS

TO MAIN

HARNESS

TO JUMPER

HARNESS

TO JUMPER

HARNESS

TO PROPANE

LOCK OFF VALVE

TO STARTER

SOLENOID

1

3

5

7

2

4

6

8

BLACK

VIOLET

WHITE

ORG / WHT

BLACK BLACK

JUMPER HARNESS

5405276

12

OIL

PRESSURE

SWITCH

NO

NC

COMMON

YELLOW

YELLOW

YELLOW

ORG / BLK

BLACK

BLACK

12

PROPANE

SOLENOID

PROPANE LOCK

OFF VALVE

5404096

Supplemental Parts List - Electrical Schematic - Ignition Grounding

Circuit / Operator Presence

Not for

Reproduction

25

Supplemental Parts List - Electrical Schematic - PTO Clutch Circuit

RELAY

START

WHITE 4"

BLUE 33"

SPLICE

SPLICE #5

GRN

21850

2

2

1

8

1

ORN

O/W

GRY

20906

GRN

ORANGE/GREEN 16"

21850

O/BK

BLK

GRY

O/W

O/BKGRY

VIO

RED

RED

VIO

20906

SPLICE

STARTER

GRY

20906

YEL

RED

BLK

VIO

BLU

GRY

BLK

20906

87A

30

87

86

85

22992

22992

2

0

0

87

20087

GRY

BLK

2

0

0

9

0

O/BK

GRAY 15"

O/BK

21548

SPLICE

SPLICE

SPLICE

SPLICE

SPLICE

20090

2X ORANGE/GREEN 16"

SPLICE #7

WHT

O/W

VIO

BRAKE

WHITE 39"

SPLICE #4

ORANGE / WHITE 8"

VIOLET 8"

BLACK 50"

W

H

I

T

E

5

"

SPLICE #3

BLUE 8"

SPLICE #6

BLUE 8"

ORANGE 58"

GREEN 65"

BLUE 21"

ORANGE / GREEN 38"

21548

GRAY 4"

RED 9" (12 GA)

RED 54" (12GA)

VIOLET 20"

YELLOW 18"

BLACK 20"

YELLOW 44"

GRAY 54"

BLACK 21"

RELAY

SHUT DOWN

GRAY 10"

SWITCH

ORANGE /

SWITCH

NEUTRAL

LEFT HAND

ENGINE

SWITCH

SEAT

SWITCH

CLUTCH

BLACK 8"

BK

GRAY 10"

VIOLET 9"

PTO

PARKING

MODULE

DELAY

TIME

SPLICE

SWITCH

GREEN 4"

YELLOW 27"

KEY

5020907

5021850

5020907

5020906

5020907

5020906

5023133

SPLICE #1

WHITE 16"

ORANGE / WHITE 45"

5022992

TO

5020914

5021517

5023133

BLACK 19"

BLACK 17"

5022992

5020087

GROUND

5020907

ORANGE / BLACK 68"

VIOLET 5"

BLACK 21"

BLACK 19"

SPLICE #2

ORANGE / BLACK 13"

5020906

BLU

5020087

5020907

5021850

AUXILIARY

HEADLIGHT /

5020907

5023494

5020914

5021092

5020907

5020090

5020906

5020907

5021

548

5020907

5021548

HARNESS

SWITCH

AUXILARY

HEADLIGHT /

5020907

5020910

5020907

5022181

HOURMETER

5020090

SOLENOID

5020907

5021850

STARTER

SWITCH

ORANGE / WHITE 10"

SPLICE #8

BLACK 8"

NEUTRAL

RIGHT HAND

WHT

O/W

O/G

VIOLET 33"

86

87

85

87A

30

BLUE

O/G

ORN

O/G

YEL

YEL

O/G

VIO

TO FUSE

BLOCK

SEAT

SWITCH

5022198

NC

NC

LH NEUTRAL

SWITCH

5021451

NO

TIME DELAY MODULE

SCHEMATIC

PARKING BRAKE

SWITCH

5022182

NC

NO

HOURMETER

5100996

RH NEUTRAL

SWITCH

5021451

NO

12

5

6

34

7

8

TO FUSE BLOCK

HARNESS

PTO

SWITCH

5022180

COMNONC

RELAY

5021766

85

86

30

87A

87

85

86

30

87A

87

PTO CLUTCH

5100084

AUXILARY

SWITCH

AUXILARY

CONNECTOR

M

L

G

B

S

IGNITION

SWITCH

5020927

A

1 2

34

5

BATTERY

NEGATIVE BATTERY CABLE

5044014

POSITIVE BATTERY CABLE

5021405

43

8

7

21

6

5

20A

20A

20A

20A

FUSE BLOCK HARNESS

5401328

RED

RED

VIOLET

VIOLET

GRAY

GRAY

ORANGE/BLACK

ORANGE/BLACK

TO ENGINE

BLOCK

GREEN

ORANGE

ORANGE / GREEN

ORANGE /

GREEN

ORANGE /

GREEN

BLUE

BLUE

ORANGE / BLACK

YELLOW

YELLOW

BLACK

BLACK

BLACK

BLACK

BLACK

WHITE

YELLOW

VIOLET

VIOLET

VIOLET

ORANGE / WHITE

BLUE

ORANGE / WHITE

ORANGE / WHITE

BLACK

RELAY

5021766

TO ENGINE

HARNESS

1

5

4

3

2

1

456

3 2

BLUE

YELLOW

WHITE

WHITE

GREEN

BLACK

BLACK

BLACK

BLACK

GRAY

RED

RED

VIOLET

GRAY

GRAY

VIOLET

ORANGE / WHITE

ORANGE / BLACK

BLACK

GRAY

GRAY

Main Harness Part No:

5402942

IGNITION SWITCH

POSITION CIRCUIT MAKE

1. OFF G & M & A

2. RUN B & L & A

3. STARTB & L & S

1

3

5

7

2

4

6

8

IGNITION

BROWN

BLACK

RED

32 HP BRIGGS & STRATTON ENGINE (PROPANE READY)

GROUND

VOLTAGE REGULATOR

STARTER

MOTOR

1

3

5

2

4

6

YELLOWYELLOW