Series 1800 Low Differential Pressure Switches

for General Industrial Service

Specications - Installation and Operating Instructions

Bulletin E-53

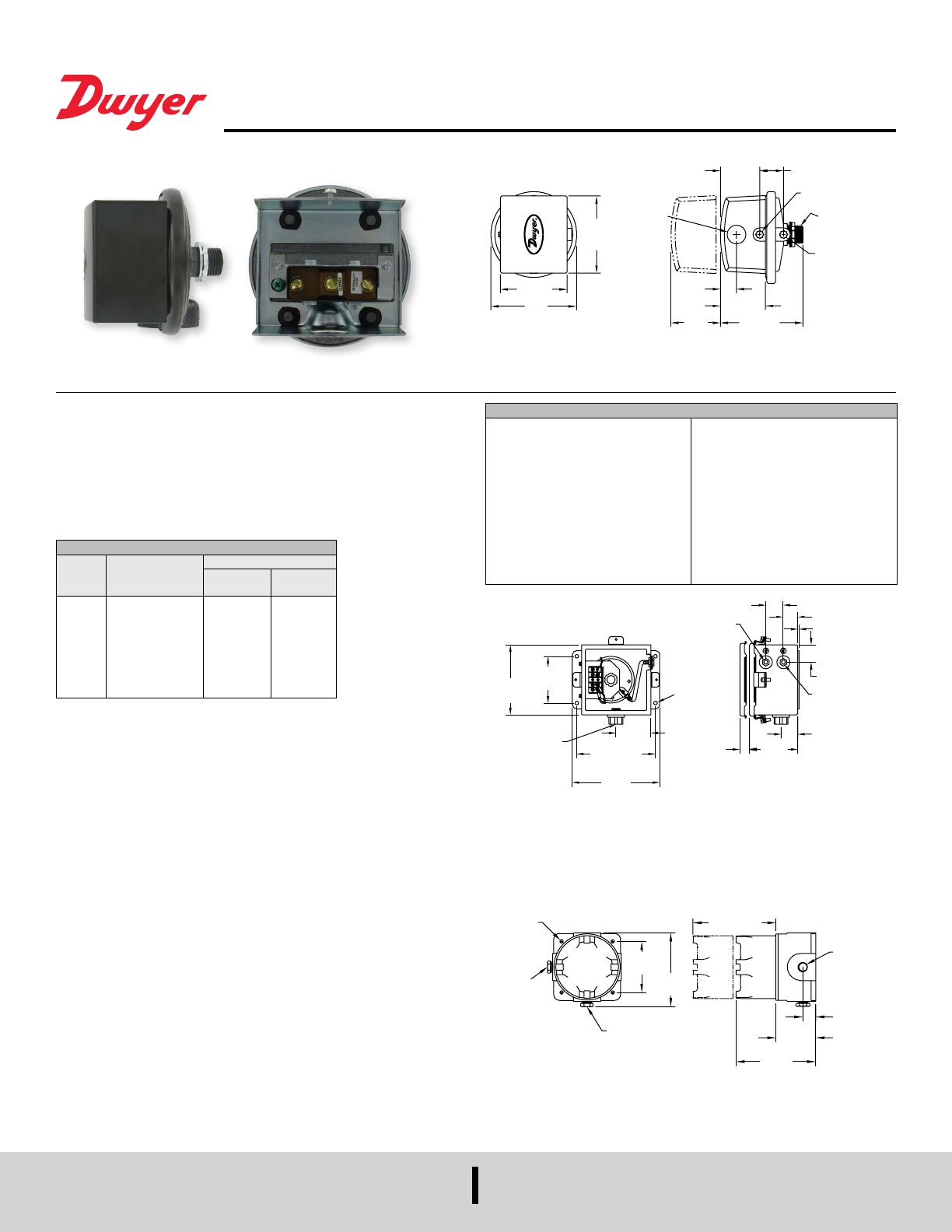

3-39/64

[91.68]

Ø7/8 [22.23]

CONDUIT

CONNECTION

3-1/8

[79.38]

Ø4

[101.60]

1-27/32

[46.83]

[28.57]

1/8 FEMALE NPT

HIGH PRESSURE

CONNECTION

1/2 MALE NPT

1/8 FEMALE NPT

LOW PRESSURE

CONNECTION

3-27/32

[97.63]

2-3/32

[53.18]

2-1/8

[53.98]

CLEARANCE FOR

3/4

[19.05]

Construction and dimensions. Series 1823 pressure switches.

Model 1823 pressure switch.

UL and CSA Listed, FM and

CENELEC approved.

One of our most popular pressure switches. Combines small size and low price with

2% repeatability for enough accuracy for all but the most demanding applications.

Set point adjustment inside the mounting switch on one side of a wall or panel with

adjustment easily accessible on the opposite side.

*Model 1823 shown; (1823 replaces 1820, 1821 and 1822 which are similar).

Environmental (MIL) Switch

Unlisted Model 1820 can be furnished with special snap switch sealed against the

environment for high humidity and/or for government applications. Similar to standard

Model 1823 except dead band is slightly greater. Specify Model 1820 (Range No.)

“MIL” in ordering.

INSTALLATION

1. Select a location free form excessive vibration and where oil or water will not drip

upon the switch. See special housings for unusual conditions.

2. While not required, positioning the pressure connections down is recommended.

Mount the switch with the diaphragm in a vertical plane. Switch with the diaphragm

in a vertical plane. Switch must be recalibrated for each change in operating

position.

3. Connect switch to source of pressure differential. Metal tubing with 1/4˝ O.D. is

recommended but any tubing system which will not restrict the air ow is

satisfactory. Note that the low pressure connection may be made to the 1/2˝ spud

at the back of the switch if desired. If so connected, drill 1/16˝ diameter holes in the

Spring Retainer ange and the head of Adjustment Screw to provide opening to the

switch interior and plug the other low pressure connection.

4. Electrical connections to the standard single pole, double throw snap switch are

provided by means of screw terminals marked “common”, “norm open”, and “norm

closed”. The normally open contacts close and the normally closed contact open

when pressure increases beyond the set point.

5. Switch loads should not exceed the maximum specied current rating of 15 amps

resistive. Switch capabilities decrease with high load inductance or rapid cycle

rates. Whenever and application involves one or more of these factors, the user

may nd it desirable to limit the switched current to 10 amps or less in the interest

of prolonged switch life.

ADJUSTMENT

1. If the switch has been factory preset, check the set-point before placing in service

to assure it has not shifted in transit.

2. If switching has not been preset or it is desired to change the point, observe the

following procedure:

a. To adjust the set point turn the slotted Adjustment Screw clockwise to increase

the set point and counterclockwise to decrease the set point.

b. The following is a recommended procedure for calibrating or checking

calibration: Use a “T” assembly with three rubber tubing leads, all as short as

possible and the entire assembly offering minimum ow restriction. Run

one lead to the pressure switch, another to a manometer of known accuracy

and appropriate range, and apply pressure through the third tube. Make nal

approach to the set point slowly. Note the manometer and pressure switch will

have different response characteristics due to different internal volumes,

lengths of tubing, oil drainage, etc. Be certain switch is checked in position it will

assume in use, i.e. vertical, horizontal, etc.

SPECIFICATIONS

Service: Air and non-combustible,

compatible gases.

Wetted Materials: Consult factory.

Temperature Limits: -30 to 180°F (-34

to 82.2°C). 1823-00, -20 to 180°F (-28.9

to 82.2°C).

Pressure Limits: 10 psig (68.95 kPa)

continuous, 25 psig (172.4 kPa) surge.

Switch Type: Single-pole double-throw

(SPDT).

Repeatability: ±2%.

Electrical Rating: 15 A @ 120-480 VAC,

60 Hz. Resistive 1/8 HP @125 VAC, 1/4

HP @ 250 VAC, 60 Hz. De-rate to 10 A

for operation at high cycle rates.

Electrical Connections: 3 screw type,

common, normally open and normally

closed.

Process Connections: 1/8˝ female

NPT.

Mounting Orientation: Diaphragm in

vertical position. Consult factory for

other position orientations.

Set Point Adjustment: Screw type

inside mounting spud.

Weight: 1 lb, 5 oz (595 g).

Agency Approvals: CE, UL, CSA, FM.

MODEL CHART

Model

Operating Range,

in w.c.

Approximate Dead Band

At Min.

Set Point

At Max.

Set Point

1823-00

1823-0

1823-1

1823-2

1823-5

1823-10

1823-20

1823-40

1823-80

0.07 to 0.22

0.15 to 0.5

0.3 to 1.0

0.5 to 2.0

1.5 to 5.0

2.0 to10

3 to 22

5 to 44

9 to 85

0.05

0.06

0.08

0.10

0.14

0.18

0.35

0.56

1.30

0.05

0.06

0.08

0.12

0.28

0.45

0.70

1.10

3.0

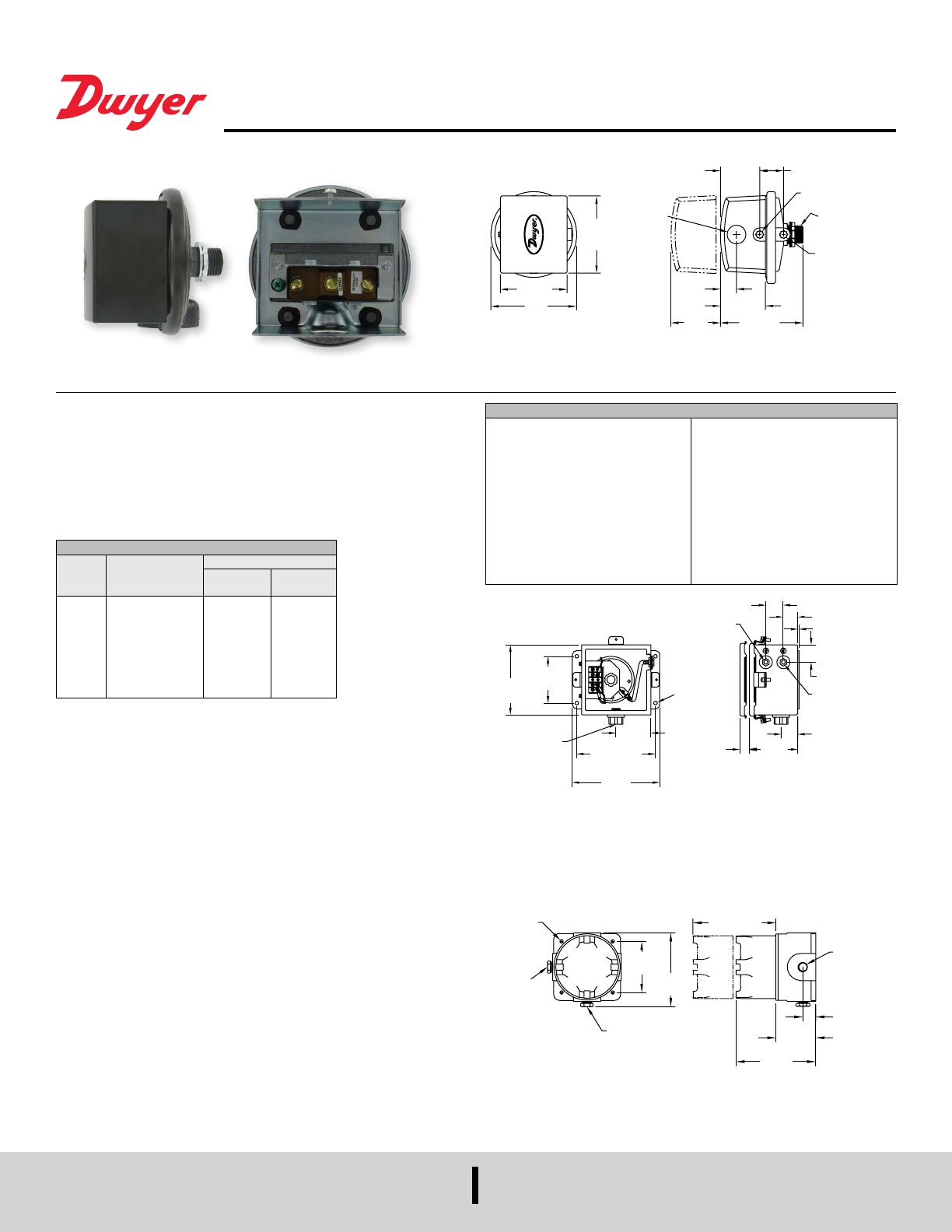

Weatherproof Enclosure

16 ga. steel enclosure for unusually wet or oily conditions. Withstands 200 hour salt

spray test. Gasketed cover. Weight 5-1/2 lb (2.5 kg). Switch must be installed at

factory. Specify “WP” in addition to switch catalog number.

Explosion-Proof Housing

Cast iron base and aluminum dome cover. Approximate weight 7-1/2 lb (3.4 kg).

Specify “EXPL” in addition to switch catalog number. Rated Class I, Groups C & D,

Div. 1. Class II, Groups E, F, & G, Div. 1.

1/8 FEMALE NPT

LOW PRESSURE

CONNECTION

1-1/4 [31.75]

3/32 [2.38]

1/8 FEMALE NPT

HIGH PRESSURE

CONNECTION

1-7/16

[36.53]

4-1/6

[103.19]

3/4

[19.05]

CLEARANCE FOR

COVER REMOVAL

Ø5/16 [7.94]

MOUNTING

HOLES TYP

4 PLACES

SQ

4 [101.60]

TYP

1/2 FEMALE

NPT CONDUIT

CONNECTION

3

[76.20]

6-3/4

[171.45] TYP

7-1/2

4X Ø.281

[7.14]

2X 4-1/4

[107.95]

2X 6-1/8

[155.58]

1/8 FEMALE NPT

LOW PRESSURE

CONNECTION

1/8 FEMALE

NPT HIGH

PRESSURE

CLEARANCE FOR

COVER REMOVAL

1/2 NPT

PROCESS

3X 1-1/16

[26.99]

3

[76.20]

6-5/8

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com

e-mail: info@dwyermail.com