Euro-Pro 8135H El manual del propietario

- Categoría

- Máquinas de coser

- Tipo

- El manual del propietario

Model 5 Instruction Manual

Modelo 5 Manual de Instrucciones

Model 5 Manuel d'Instructions

813 H

813 H

813 H

La página se está cargando...

La página se está cargando...

IMPORTANTES MESURES DE SÉCURITÉ

Lorsqu'on utilise une machine à coudre, il

faut toujours respecter certaines règles

fondamentales de sécurité, notamment

les suivantes:

1. Ne pas laisser sans surveillance

lorsque branchée. Toujours débrancher

la machine immédiatement après

usage et avant de la nettoyer.

2. Toujours débrancher avant de changer

l'ampoule. Remplacer l'ampoule par

une ampoule de même calibre 10

watts (110-120V area) ou 15 watts

(220-240 area).

1. Ne pas permettre l'utilisation comme

jouet. Exercer une étroite surveillance

lorsque la machine est utilisée à

proximité d'un enfant ou lorsqu'elle

est utilisée par ce dernier.

2. N'utilisez cette machine à coudre que

pour l'utilisation décrite dans ce

manuel. N'utiliser que les accessoires

recommandés par le manufacturier

décrits dans ce manuel.

3. Ne pas utiliser cette machine à

coudre si le cordon ou la prise sont en

mauvais état, si elle ne fonctionne

pas normalement, si elle est tombée

et endommagée, ou plongée dans

l'eau. Retourner la machine à coudre

chez le dépositaire autorisé le plus

près pour examen, réparations,

réglages électriques ou mécanique.

4. Ne jamais utiliser la machine à coudre

lorsque les trous d'aération sont

bloqués. Garder les trous d'aération

de la machine à coudre et de la

commande de vitesse libres de toute

accumulation de charpie, poussières et

tissus.

5. Ne jamais échapper ou insérer tout

objet dans les ouvertures.

6. Ne pas utiliser à l'extérieur.

7. Ne pas utiliser dans un endroit où des

produits aérosol sont utilisés on dans

un endroit où on administre de

l'oxygène.

8. Mettre la machine hors tension avant

de la brancher ou de la débrancher.

9. Ne pas tirer sur le cordon pour

débrancher la machine à coudre. Pour

débrancher, saisir la fiche et tirer.

10. Tenir les doigts éloignés des pièces

mobiles. Tout spécialement de l'aiguille.

11. Toujours utiliser la plaque à aiguille

appropriée.

12. Ne pas utiliser d'aiguille croche.

13. Ne pas tirer ou pousser sur le tissu en

cousant, afin d'éviter de briser l'aiguille.

14. Mettre la machine hors tension pour

effectuer tout réglage, tel enfiler

l'aiguille, changer l'aiguille ou plaque

aiguille.

15. Toujours débrancher la machine à

coudre pour effectuer l'entretien ou

tout autre réglage mentionnés dans ce

manuel.

16. Le niveau du son est dans des

conditions normales de 75dB (A).

Lire toutes les directives avant usage.

- Pour éviter les risques

de secousses électriques:

- Afin de réduire les risques

de brûlures, feu, risques de secousses

électriques, ou blessures:

DANGER

AVIS

CONSERVER CES

INSTRUCTIONS

F

La página se está cargando...

List of contents

GB

Principal parts .................................................................................................................2/4

Accessories........................................................................................................................6

Fitting the snap-in sewing table..........................................................................................8

Connecting machine to power source..............................................................................10

Changing the bulb............................................................................................................12

Two-step presser foot lever/ Adjusting the presser foot pressure....................................14

Attaching the presser foot holder .....................................................................................16

Winding the bobbin ..........................................................................................................18

Inserting bobbin................................................................................................................20

Changing the needle (system 130/ 705H)........................................................................22

Threading the upper thread..............................................................................................24

Automatic needle threader...............................................................................................26

Thread tension .................................................................................................................28

Bringing up the lower thread ............................................................................................30

Reverse sewing/ Changing sewing directions/

Removing the work/ Cutting the thread.......................................................................32

How to drop feed dog.......................................................................................................34

Matching needle / fabric / thread......................................................................................35

How to choose your pattern .............................................................................................38

Straight stitching and needle position ..............................................................................40

Zig zag sewing .................................................................................................................42

Blind hem/ lingerie stitch ..................................................................................................44

Overlock stitches..............................................................................................................46

Sewing on buttons............................................................................................................48

How to sew buttonholes (one-step buttonhole)................................................................50

Left and right side balance for buttonhole........................................................................52

Zippers and piping............................................................................................................54

Sewing with the hemmer foot...........................................................................................56

3-step zig-zag...................................................................................................................58

Stitch selection.................................................................................................................60

Smocking stitch................................................................................................................62

Sewing with the cording foot ............................................................................................64

Free motion darning.........................................................................................................66

Practical stitches ..............................................................................................................68

Darning.............................................................................................................................70

Attaching lace...................................................................................................................72

Applique ...........................................................................................................................74

Twin needle......................................................................................................................76

Monogramming and embroidering with embroidery hoop* ..............................................78

Quilting.............................................................................................................................80

Gathering .........................................................................................................................82

Scallop stitching ...............................................................................................................84

Patch work .......................................................................................................................86

The walking foot accessory (optional)..............................................................................88

Side Cutter .......................................................................................................................90

Maintenance.....................................................................................................................92

Trouble shooting guide.....................................................................................................94

La página se está cargando...

F

Sommaire

Pièces principales de la machine....................................................................................3/5

Accessoires........................................................................................................................7

Mise en place de la table-rallonge .....................................................................................9

Branchement de la machine à coudre .............................................................................11

Changement de l'ampoule ...............................................................................................13

Levier du pied-de-biche à deux positions/ Ajustement de la pression du pied-de-biche .15

Montage du support du pied-de-biche .............................................................................17

Remplir la canette ............................................................................................................19

Mise en place de la canette .............................................................................................21

Mise en place de l'aiguille (Système 130/705H) ..............................................................23

Enfilage fil supérieur.........................................................................................................25

Enfileur automatique ........................................................................................................27

Tension du fil....................................................................................................................29

Remonter le fil inférieur....................................................................................................31

Marche arrière/ Pour modifier le sens de la couture/

Retrait de l'ouvrage/ Couper les fils ............................................................................33

Escamotage de la griffe d'entraînement ..........................................................................34

Tableau des aiguilles et fils..............................................................................................37

Sélection des points.........................................................................................................39

Couture au point droit et position d'aiguille ......................................................................41

Couture au point zig-zag..................................................................................................43

Ourlet au point invisible....................................................................................................45

Point overlock...................................................................................................................47

Pose des boutons ............................................................................................................49

Coudre les boutonnières/ boutonnières à une étape .......................................................51

Equilibrage droit et gauche de la boutonnière..................................................................53

Pose d'une fermeture à glissière......................................................................................55

Coudre avec le pied ourleur.............................................................................................57

Point zig-zag cousu..........................................................................................................59

Sélection des points.........................................................................................................61

Point nid d'abeille .............................................................................................................63

Coudre avec le pied pour cordonnet................................................................................65

Reprise.............................................................................................................................67

Points utilitaires................................................................................................................69

Reprisage.........................................................................................................................71

Pose de la dentelle...........................................................................................................73

Appliqué ...........................................................................................................................75

Couture à deux aiguilles...................................................................................................77

Monogramme et broderie à main libre*............................................................................79

Coudre avec le guide .......................................................................................................81

Le fronçage ......................................................................................................................83

Point feston ......................................................................................................................85

Patchwork ........................................................................................................................87

Pied de transport supérieur (optionnels)..........................................................................89

Coupeur latéral.................................................................................................................91

Entretien de la machine ...................................................................................................93

Comment remédier soi-même aux petits problèmes ......................................................96

La página se está cargando...

F

E

3

Pièces principales de la machine

Descripción de la máquina

1. Tensión del hilo

2. Presiion de pie

3. Palanca tensora del hilo

4. Corta-hilos

5. Pié prensa tela

6. Chapa aguja

7. Mesa plana deslizable y caja de accesorios

8. Dial para puntada zigzag

9. Dial de longitud de puntada

10. Eje para el bobinado

11. Disco visor

12. Iman

13. Palanca reversora de costura

14. Palanca para bajar los dientes de alimentación

15. Palanca de un paso coser ojales

16. Enhebrador automático

1. Régulateur de tension du fil

2. Régulateur de pression du pied-de-biche

3. Releveur de fil

4. Coupe-fil

5. Pied-de-biche

6. Plaque à aiguille

7. Table-rallonge et boîtier pour les accessoires

8. Bouton pour la largeur du point

9. Bouton pour la longueur du point

10. Butée du bobineur

11. Affichage du point

12.

13. Levier de marche arrière

14. Abaissement du transporteur

15. Levier de boutonnière à une étape

16. Enfileur automatique

Aimant

GB

4

Principal parts

18

19

20

21

22

17

25

24

23

27

26

17. Handle

18. Bobbin winder

19. Spool pin

20. Handwheel

21. Pattern selector dial

22. Power switch

23. Main plug socket

24. Bobbin thread guide

25. Upper thread guide

26. Presser foot lever

27. Buttonhole stitch balance adjustment slot

La página se está cargando...

6

GB

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

k. Spool pin felt (2x)

l. Satin stitch foot

m.Overcasting foot

n. Hemmer foot

o. Blind hem foot

p. Cording foot

q. Quilting foot

r. Darning/ Embroidery foot

s. Gathering foot

t. Walking foot

u. Side cutter

v. Twin needle

Standard accessories (1) Bonus feet (2) Optional accessories (3)

All purpose foot

Zipper foot

Button sewing foot

Buttonhole foot

L-screwdriver

Seam ripper/ brush

Oil bottle

Pack of needles (3x)

Bobbin (3x)

Seam guide

(These 1 accessories are

not supplied with this

machine; they are however

available as special

accessories from your local

dealer.)

Accessories

t

u

l

s

r

nom

1

2

p

3

ab dc

e

f

g

jhi

k

v

q

La página se está cargando...

GB

Fitting the snap-in sewing table

Hold the snap-in sewing table horizontal, and push it

in the direction of the arrow. (1)

The inside of the snap-in sewing table can be utilized

as an accessory box.

To open, lift up at the point of the arrow. (2)

8

2

1

La página se está cargando...

GB

Connecting machine to power source

10

a

b

3

4

1

2

A

B

Caution:

Attention:

Always make sure that the machine is unplugged from power source

and the main switch is on "O". when the machine is not in use and

before inserting or removing parts.

Consult a qualified electrician if in doubt as to connect machine to

power source. Unplug power cord when machine is not in use.

The appliance must be used with the foot controller 4C-316B (110-

120V area)/ 4C-326G (230V area)/ 4C-316C or 4C-326C (220-240V

area) manufactured by MATSUSHITA ELECTRIC (TAIWAN) CO.,

LTD.

- This machine is equipped with a polarized plug which must be used

with an appropriate electrical outlet.

- Connect the machine to a power source as illustrated (1/2).

- The power switch is located above the terminal box. Your machine

will not operate unless this switch is on " I ". (1)

- Sewing light turns on automatically when the main switch is on " I ".

- To start the machine, press on the foot control (4). The speed of

the machine is regulated by the amount of pressure exerted on the

foot control.

a. Polarized attachment plug

b. Conductor intended to be grounded

IMPORTANT NOTICE

For appliance with a polarized plug (one blade is wider than the other).

To reduce the risk of electric shock, this plug is intended to fit in a

polarized outlet only one way. If it does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a qualified electrician to

install the proper outlet. Do not modify the plug in any way. (3)

La página se está cargando...

GB

Changing the bulb

Caution:

Make sure to disconnect the electrical supply plug

from wall outlet before changing light bulb.

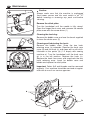

- Loosen screw (A) as illustrated. (1)

- Remove the cover (B).

- Unscrew the bulb and fit new one (C). (2)

- Replace the cover and tighten screw.

Replace bulb with same type rated 10 watts (110-

120V area) or 15 watts (220-240V area).

12

1

A

B

2

C

La página se está cargando...

GB

A

Adjusting the presser foot pressure

Two-step presser foot lever

When sewing several layers or thick fabrics, the

presser foot can be raised a second stage for easy

positioning of the work. (A)

The presser foot pressure of the machine has been

pre-set and requires no particular readjustment

according to the type of fabric (light-or-heavy weight).

However, if you need to adjust the presser foot

pressure, turn the presser adjusting screw with a coin.

For sewing very thin fabric, loosen the pressure by

turning the screw counter clockwise, and for heavy

fabric, tighten by turning it clockwise.

14

F

E

15

La presiõn del pie prensatela de la máquina ha sido preseleccionada y no requiere

especiales ajustes de acuerdo con el tipo de tejido (liviano o pesado).

Sin embargo, si se necesita ajustar la presión del pie presatela gire el tornillo de ajuste

de presión con una moneda. Para coser tela muy fina afloje la presión girando el tornillo

en sentido antihorario y para telas pesadas aumente la presión girán dolo en sentido

horario.

Ajuste de la presión del pié prensatela

Para coser ropas extremamente gruesas se puede ensanchar el pasaje de la ropa

debajo del pie subiendo la palanca del alza-prensatelas de un escalón. (A)

Palanca para levantar el pié prénsatela con dos posiciones

Pour faciliter l'insertion de tissus très épais sous le pied-de-biche, on peut augmenter

l'espace entre le pied-de-biche et la plaque à aiguille, en relevant le levier du pied-de-

biche d'un cran.

Lever du pied-de-biche à deux positions

Le régulateur de pression du pied-de-biche a été ajusté et devrait convenir à tous les

types de tissus (du plus fin au tissu épais).

Cependant, si un ajustement s'avère nécessaire, tournez la vis d'ajustement en vous

servant d'une pièce de monnaie.

Pour les tissus très fins, desserrer le régulateur de pression en tournant dans le sens

contraire des aiguilles d'une montre, et pour les tissus épais, augmenter la pression en

tournant la vis dans le sens des aiguilles d'une montre.

Ajustement de la pression du pied-de-biche

GB

Attaching the presser foot holder

Attention:

Turn power switch to "O" before carrying out any of the

operations below.

Raise the needle to its highest position and raise the

presser foot lever. Attach the presser foot holder (b) to

the presser foot bar (a). (1)

Lower the presser foot holder (b) until the cut-out (c) is

directly above the pin (d). (2)

Lower the presser foot holder (b) and the presser foot (f)

will engage automatically.

Raise the presser foot.

Release the pressure foot by raising lever (e) located at

the back of the foot holder. (3)

Attach the seam guide (g) in the slot as illustrated. Adjust

the distance as required for hems, pleats, etc.... (4)

Attaching the presser foot:

Removing the presser foot:

Attaching the seam guide:

16

4

1

2

3

e

b

a

a

c

d

e

f

b

g

La página se está cargando...

GB

Winding the bobbin

a

18

1

Please Note:

When the bobbin winder spindle is in

"bobbin winding" position, the machine

will not sew and the hand wheel will

not turn. To start sewing, push the

bobbin winder spindle to the left

(sewing position).

a. Spool pin felt

Press the foot control gently. The bobbin will stop winding when it is full. Push the bobbin to

the left to "sewing position" and remove it.

Place an empty bobbin on the

bobbin winder spindle.

Take the thread from the spool

through the bobbin winder

tension disc. (1)

Wind the thread a few times by

hand around the empty bobbin in

a clockwise direction. Push the

bobbin to the right towards the

bobbin winding position. (2)

2

La página se está cargando...

GB

Inserting bobbin

Attention:

Turn power switch to "O" before inserting or removing the

bobbin.

When inserting or removing the bobbin, the needle must be

fully raised.

- Open the hinged cover. (1)

- Hold the bobbin case with one hand. Insert the bobbin so

that the thread runs in a clockwise direction (arrow). (2)

- Pull the thread through the slot, down and to the left until it

enters the delivery eyelet (rectangular opening) under the

tension spring. (3)

- Hold the bobbin case by the hinged latch. (4)

- Insert the bobbin case fully into the shuttle race and release

the latch. Make sure that the metal finger fits into the notch

at the top of the race cover. (5)

20

3

4

1

2

5

La página se está cargando...

Caution:

Turn power switch to "O" before

inserting or removing the needle.

Replace the needle at the first sign of

thread breakage or skipped stitches.

Select the correct type and size of

needle for the fabric to be sewn. Turn

the balance wheel towards you until

the needle is at highest position.

Loosen the needle clamp screw (A)

and tighten again after inserting the

new needle. (1)

The flat side of the needle shaft

should be facing away from you (B).

Push the needle up (C) into the

needle clamp as far as it will go (D).

Tighten the needle clamp screw firmly.

The sewing needle must always be

straight and sharp for smooth sewing.

Replace the needle (2) if it is bent (A),

blunt (B) or the point is damaged (C).

GB

Changing the needle (System 130/705H)

A

B

C

D

22

1

2

AB

C

La página se está cargando...

24

Threading the upper thread

GB

Caution:

Before threading, turn power

switch to "O".

Raise the needle bar to its highest

position. Follow exactly the

numbered threading sequence

illustrated below. If you skip a step

or fail to properly engage the

thread in any of the thread guides,

the machine will not sew properly.

(1-5)

Continue to draw the thread down

and into the needle bar thread

guide. Insert the thread through

the eye of the needle from front to

back. Leave about 10 cm (4") of

thread loose behind the needle. (6)

a. Spool pin felt

1

2

6

3

4 5

a

La página se está cargando...

- Raise the needle to its highest

position.

- Press lever (A) right down.

- The threader automatically

swings to the threading position

(B).

- Take the thread around the

hook (C).

- Take the thread in front of the

needle round the hook (D)

from bottom to top.

- Release lever (A).

- Pull the thread through the

needle eye.

Attention:

Turn power switch to off ("O")!

26

2

1

A

B

D

C

A

C

A

C

B

D

Automatic needle threader

GB

La página se está cargando...

GB

Thread tension

28

1

B

C

A

Note:

The bobbin thread tension has

been adjusted at the factory and

readjustment is usually not

required.

Lower thread tension

To test the bobbin thread

tension, remove the bobbin case

and bobbin from the machine

and hold the bobbin case

suspended by the thread. Shake

it once or twice. If the tension is

correct, the thread will unwind

by about an inch or two. If the

tension is too tight, it will not

unwind. If the tension is too

loose, the thread will unwind for

more than two inches.

To adjust, turn the small screw

on the side of the bobbin case.

(1)

Upper thread tension

Basic thread tension setting: "4". (2)

To increase the tension, turn the dial up to a higher number. To reduce the tension, turn

the dial to a lower number.

A. Normal thread tension.

B. Thread tension too loose.

C. Thread tension too tight.

2

La página se está cargando...

30

Bringing up the lower thread

GB

Hold the upper thread with the left

hand. Turn the handwheel towards

you with your right hand until the

needle goes down and comes up

again to its highest position. (1)

- Lightly draw the needle thread

forming a loop with the bobbin

thread. The upper thread should

have caught the lower thread in a

loop.

- Pull the needle thread toward you

and the lower thread will come up

from the bobbin in a large loop. (2)

Pull about 15 cm. (6") of both thread

away from you under the presser

foot.

1

2

La página se está cargando...

B

32

Reverse sewing

GB

Reverse sewing is used for locking the end of seams and

where reinforcement is needed. At the end of seam, press

down the reverse sewing lever and touch the foot control

lightly. Sew a few reverse stitches. Release the lever and

the machine will sew forwards again (A).

A

1. Stop the machine at the point where you wish to change

directions with the needle still in the fabric.

2. Raise the presser foot and turn the fabric to line up its

new direction using the needle as a turning point.

3. Lower the presser foot and start sewing in the new

direction.

Turn the handwheel towards you to bring the thread take

up lever to its highest position. Raise the presser foot and

draw the fabric away from you.

Cutting the thread

Hold the threads behind the presser foot. Using both hands,

guide them to the slit (B) at the rear of the presser bar and

press down to cut the thread. You can also use the thread

cutter on the side of the machine.

Removing the work

Changing sewing directions

La página se está cargando...

34

For ordinary sewing, keep the feed dog up, for

freehand embroidery, sewing on buttons and darning,

drop the feed dog.

To raise (a) and lower (b) feed dog.

How to drop feed dog

GB

Los dientes de arrastre están en posición arriba para

los trabajos de costura habituales.

Colocar la palanca (a) hacia la izquierda.

El transportador se coloca automa-ticamente arriba

desde la primera puntada.

Es necesario bajar los dientes de arrastre para

ciertos trabajos en los cuales la tela no debe ser

transportadas como, por ejemplo, zurcidos o

bordados con bastidor.

Poner la palanca (b) hacia la derecha.

Bajar los dientes del alimentador

E

Pour les travaux de couture usuels, la griffe

d'entraînement reste en position haute. Pousser le

levier (a) vers la gauche.

Le transporteur est automatiquement repoussé vers

le haut dès le premier point. Pour certains travaux tels

que le reprisage ou la broderie à mains libres,

l'ouvrage ne doit pas être entraîné. Il faut donc

abaisser la griffe d'entraînement. Pousser le levier (b)

vers la droite.

Escamotage de la griffe d'entraînement

F

a

b

a

b

2

1

Matching needle / fabric / thread

GB

NEEDLE, FABRIC, THREAD SELECTION GUIDE

NEEDLE SIZE FABRICS THREAD

9-11(65-75)

12(80)

Lightweight fabrics-thin cottons, voile,

serge, silk , muslin, Qiana, interlocks,

cotton knits, tricots, jerseys, crepes,

woven polyester, shirt & blouse fabrics.

Medium weight fabrics-cotton, satin,

kettleclote, sailcloth, double knits,

lightweight woollens.

Medium weight fabrics-cotton duck,

woolen, heavier knits, terrycloth,

denims.

Heavyweight fabrics-canvas, woolens,

outdoor tent and quilted fabrics,

denims, upholstery material (light to

medium).

Heavy woollens, overcoat fabrics,

upholstery fabrics, some leathers and

vinyls.

IMPORTANT: Match needle size to thread size and weight of fabric

NEEDLE, FABRIC SELECTION

14(90)

16(100)

18(110)

Light-duty thread in cotton,

nylon or polyester.

Most threads sold are medium

size and suitable for these

fabrics and needle sizes. Use

polyester threads on synthetic

materials and cotton on natural

woven fabrics for best results.

Always use the same thread on

top and bottom.

Heavy duty thread, carpet

thread. (Use heavy foot

pressure-large numbers.)

Standard sharp needles. Sizes

range thin to large. 9 (65) to 18

(110)

Semi-ball point needle, scarfed.

9 (65) to 18 (110)

Full ball point needle 9 (65) to

18 (110)

Leather needles. 12 (80) to 18

(110)

Note:

1. Twin needles, can be purchased for utility and decorative work.

2. When sewing with twin needles, the stitch width dial should be set at less than "2.5".

3. European needles show sizes 65, 70, 80 etc. American and Japanese needles show size 9, 11,

12 etc.

4. Replace needle often (approximately every other garment ) and / or at first thread breakage or

skipped stitches.

Natural woven fabrics-wool, cotton, silk,

etc. Qiana. Not recommended for

double knits.

Natural and synthetic woven fabrics,

polyester blends. Knits-polyesters,

interlocks, tricot, single and double

knits. Can be used instead of 15 1 for

sewing all fabrics.

NEEDLES EXPLANATION TYPE OF FABRIC

Sweater knits, Lycra, swimsuit fabric,

elastic.

Leather, vinyl, upholstery. (Leaves

smaller hole than standard large

needle.)

HA 1

15 1

15 1/705H

(SIN)

15 1/705HS

(SUK)

130 PCL

35

La página se está cargando...

F

Tableau des aiguilles et fils

37

SÉLECTION DE L'AIGUILLE PAR RAPPORT AU TISSU

Aiguilles régulières et universelles.

Grosseurs disponibles de 9 (65)

à 18 (110).

Aiguilles à demi-bille. Grosseurs

disponibles 9 (65) à 18 (110).

Aiguilles à bille entière.

Grosseurs disponibles 9 (65) à

18 (110).

Aiguilles robustes à pointe

universelle, 14 (90) à 18 (110).

Remarque:

1. Les aiguilles jumelles peuvent être achetées dans un but utilitaire ou décoratif.

2. Quand vous cousez avec les aiguilles jumelles, le bouton de largeur de point doit être au moins

sur le chiffre "2.5" et moins.

3. Les aiguilles européennes sont numérotées 65, 70, 80 etc. Les aiguilles américaines et

japonaises sont numérotées 9, 11, 12 etc.

4. Changer souvent les aiguilles (après le couture d'un vêtement) et / ou à la première rupture du fil

ou des points.

Tissu en fibre naturelle: coton, lainage,

soie. Non recommand é pour tricot-

double.

Pour fibre naturelle et synthétique ou

un mélange des deux fibres: étoffe

tissé, tricot, interlock etc.

AIGUILLES DESCRIPTIONS GENRE DE TISSUS

Trico à chandail, lycra, tissu pour

costume de bain, élastique.

Denim, canevas, tissu à recouvrement,

toile.

HA 1

15 1

15 1/705H

(SIN)

15 1/705HS

(SUK)

15 x 1/ 705 HJ

GROSSEUR DE

LAIGUILLE

TISSUS

FILS

9-11(65-75)

12(80)

Tissus Légers: Coton léger, voile,

serge, mousseline, tricot de coton,

jersey, crêpes, polyester, tissu pour

blouse ou chemise.

Tissus moyens: Coton moyen, satin,

toile, tricot double , lainage léger.

Fil de coton, fil de soie, fil de

nylon ou fil synthétique.

Tissus moyens à épais: Coton épais,

lainages, tricot épais, ratine, denim,

velours côtelé.

Tissus épais: canevas, lainage épais,

toile de tente, tissu piqué, denim, tissu

à recouvrement (léger à moyen).

Tissus épais: Lainages à manteau,

tissu pour vêtements d'extéieur,

certains cuir et vinyle.

IMPORTANT: Assurez-vous que la grosseur de l'aiguille convienne à l'épaisseur du tissu à coudre

14(90)

16(100)

18(110)

Les fils vendus en magasin

conviennent à tous ces tissus et

grosseurs d'aiguilles. Utiliser le

fil synthétique pour les tissus

synthétique et le fil de coton

pour les tissus en fibre naturelle.

Assurez-vous d' avoir le même

fil sur le dessus et dans la

canette.

Fil fort, fil à denim. (Augmenter

la pression sur le pied presseur).

Aiguilles avec pointe en forme

d'angle acéré, 12 (80) à 18

(110).

Cuir, vinyle, plastique souple.130 PCL

La página se está cargando...

La página se está cargando...

40

Straight stitching and needle position

GB

1

2

3

4

5

A

Turn the pattern selector dial so

that the stitch display shows the

straight stitch position.

Generally speaking, the thicker

the fabric, thread and needle,

the longer the stitch should be.

Choose your needle position,

from center position to left

needle position by changing the

stitch width dial (1) from "0" to

"5".

1. Stitch width dial

2. Stitch length dial

3. Stitch display

4. Pattern selector dial

5. Reverse sewing lever

La página se está cargando...

42

Zig zag sewing

GB

1

2

5

0

1

2

3

4

5

4

3

21

0

0

1

2

3

4

4

3

21

0.5

S

Turn the pattern selector dial to "B".

The maximum zigzag stitch width for zigzag stitching

is "5"; however, the width can be reduced on any

pattern. The width increases as you move zigzag dial

from "0" - "5". For twin needle sewing, never set the

width wider than "2.5". (1)

The density of zigzag stitches increase as the setting

of stitch length dial approaches "0". Neat zigzag

stitches are usually achieved at "2.5" or below. (2)

When the stitch length is set between "0" - "1", the

stitches are very close together producing the "satin

stitch" which is used for making buttonholes and

decorative stitches.

When sewing very thin fabrics, it is suggested that

you use interfacing on the backside of the fabric.

Function of stitch width dial

Function of stitch length dial while zigzaging

Satin stitch

Sewing thin fabrics:

La página se está cargando...

GB

Blind hem/ lingerie stitch

44

c

d

3

4

2

1

C

D

For hems, curtains, trousers, skirts, etc.

Blind hem/ lingerie for firm fabrics. Position "C" on selection

dial.

Blind hem for stretch fabrics. Position "D" on selection dial.

Set the machine as illustrated.

Fold the fabric as illustrated with the wrong side uppermost. (1)

Place the fabric under the foot. Turn the handwheel forwards by

hand until the needle swings fully to the left. It should just pierce

the fold of the fabric. If it does not, adjust the stitch width

accordingly. (2) Adjust the guide (3) by turning the knob (4) so

that the guide just rests against the fold. Sew slowly, by pressing

the foot control lightly guiding the fabric along the edge of the

guide.

Stitch width

Stitch length

Note:

It takes practice to sew blind hems. Always make a sewing test

first.

a.

b.

c. Presser foot

d. Stitch pattern

a

b

0

1

2

3

4

S

1~2

3~5

5

0

1

2

3

4

La página se está cargando...

GB

Overlock stitches

46

1

2

3

QPI

a

b

0

1

2

3

4

S

3, S

3~5

5

0

1

2

3

4

Seams, neatening, visible hems.

Turn the stitch length dial to "3' or "S".

The stitch width can be adjusted to suit the fabric.

For fine knits, handknits, seams. (1)

For fine knits, jerseys, neck edges, ribbing. (2)

For fine knits, jerseys, neck edges, ribbing. (3)

All overlock stitches are suitable for sewing and neatening edges

and visible seams in one operation.

When neatening, the needle should just go over the edge of the

fabric.

Double overlock stitch:

Standard overlock:

Stretch overlock:

Attention:

Use new needles or ball point needles or stretch needle!

La página se está cargando...

GB

Sewing on buttons

48

2

3

1

a

b

B

a

b

a

b

0

1

2

3

4

S

0

3~5

5

0

1

2

3

4

Move the drop feed control to right side to lower the feed dogs. (1)

Change presser foot to button sewing foot.

Position the work under the foot. Place the button in the desired

position, lower the foot. Set the pattern selector knob on zig zag

stitch " ". Adjust the stitch width to "3" - "5" according to the

distance between the two holes of the button. Turn the handwheel

to check that the needle goes cleanly into the left and right holes

of the button. Set the pattern selector knob on straight stitch " ",

and sew a few securing stitches. Set the pattern selector knob on

zig zag stitch " ", and slowly sew on the button with about 10

stitches. Set the pattern selector knob on straight stitch " ", and

sew a few securing stitches. (2)

If a shank is required, place a darning needle on top of the button

and sew. (3) For buttons with 4 holes, sew through the front two

holes first (2), push work forward and then sew through the back

two holes. (3)

La página se está cargando...

50

0

1

2

3

4

S

0.5~1

3~5

5

0

1

2

3

4

How to sew buttonholes (one-step buttonhole)

GB

Buttonhole sewing is a simple process that provides reliable results.

However, it is strongly suggested to always make a practice buttonhole on

a sample of your fabric and interfacing.

1. Using tailor's chalk, mark the position of the buttonhole on the fabric.

2. Attach the buttonhole foot and set the pattern selector dial to " ". Set

stitch length dial to " ". Adjust stitch width to desired width.

3. Lower the presser foot aligning the marks on foot with the marks on the

fabric (A). (The front bar tack will be sewn first.)

4. Open the button plate and insert the button (B).

5. Lower the buttonhole lever and gently push it back (C).

6. While lightly holding the upper thread, start the machine.

7. Buttonhole stitching is done in the order (D).

8. Stop the machine when the buttonhole is sewn.

When sewing buttonholes on stretch fabric, hook heavy thread or cord

under the buttonhole foot. When the buttonhole is sewn the legs will

overcast the cord.

1. Mark the position of the buttonhole on the fabric with the tailor's chalk,

attach the buttonhole foot, and set the pattern selector dial to " ". Set

stitch length dial to " ".

2. Hook the heavy thread onto the back end of the buttonhole foot, then

bring the two heavy thread ends to the front of the foot, insert them into

the grooves and temporarily tie them there.

3. Lower the presser foot and start sewing.

* Set the stitch width to match the diameter of the gimp thread.

4. Once sewing is completed, gently pull the heavy thread to remove any

slack, then trim off the excess.

Making a Buttonhole

Making a Buttonhole on Stretch Fabrics (E)

D

E

2

1

4

3

A

B

C

PUSH

PUSH

La página se está cargando...

52

Left and right side balance for buttonhole

GB

Stitch density on right and left

sides of buttonhole can be

adjusted by buttonhole balance

control dial.

This dial should usually be in a

neutral position. (between "+"

and "")

If the stitches on the left side of

the buttonhole are too close

together, turn the dial to the left

(+).

* Turning dial to the left opens

left side.

If the stitches on the left side of

the buttonhole are too open,

turn the dial to the right ().

* Turning dial to the right closes

left side.

The stitch on the right side of

the buttonhole is set using the

stitch length dial.

La página se está cargando...

GB

Zippers and piping

54

1

2

Set the machine as illustrated. Dial selector on "A".

Set stitch length control between "1" - "4" (according to thickness of

fabric).

The zipper foot can be inserted right or left, depending on which

side of the foot you are going to sew. (1)

To sew past the zipper pull, lower the needle into the fabric, raise

the presser foot and push the zipper pull behind the presser foot.

Lower the foot and continue to sew.

It is also possible to sew in a length of cord, into a bias strip to form

a 'welt'. (2)

0

1

2

3

4

S

1~4

0

5

0

1

2

3

4

A

La página se está cargando...

GB

Sewing with the hemmer foot

56

For hems in fine or sheer fabrics.

Set the machine as illustrated. Pattern selector on "A".

Neaten the edge of the fabric. At the beginning of the hem, turn

under the edge twice by about 3 mm (1/8") and sew 4-5 stitches to

secure. Pull the thread slightly towards the back. Insert the needle

into the fabric, raise the presser foot and guide the fold into the

scroll on the foot. (1)

Gently pull the fabric edge towards you and lower the presser foot.

Begin sewing, guiding the fabric into the scroll by holding it upright

and slightly to the left. (2)

0

1

2

3

4

S

1~4

0

5

0

1

2

3

4

A

1

2

La página se está cargando...

GB

3-step zig-zag

58

Sewing on lace and elastic, darning, mending, reinforcing edges.

Set the machine as illustrated. Pattern selector on "E".

Place patch in position. The stitch length can be shortened to

produce very close stitches. (1)

When mending tears, it is advisable to use a piece of backing

fabric to reinforce. The stitch density can be varied by adjusting the

stitch length. First sew over the center and then overlap on both

sides. Depending on the type of fabric and damage, sew between

3 and 5 rows. (2)

1. Place the elastic on the fabric.

2. As you sew, stretch the elastic both in the front and behind the

presser foot as shown in fig. (3)

The elastic stitch can be used to join two pieces of fabric together

and is very effective when sewing knitted fabrics. If nylon thread is

used, the stitch will not be visible.

1. Place the edges of the two pieces of fabric together and center

them under the presser foot.

2. Sew them together using the elastic stitch taking care to keep

the two fabric edges close together as shown in fig. (4)

Sewing elastic

Joining fabric

0

1

2

3

4

S

1~2

3~5

5

0

1

2

3

4

E

3

4

21

La página se está cargando...

GB

Stitch selection

60

3

4

Triple straight stitch: (1/3)

Triple zig-zag: (2/4)

Pattern selector on "A".

For hardwearing seams.

Turn the stitch length dial to "S".

The machine sews two stitches forwards and

one stitch backwards. This gives triple

reinforcement.

Pattern selector on "B".

For hardwearing seams, hems and decorative

seams.

Turn the stitch length dial to "S".

Adjust the stitch width dial to between "3" and "5".

Triple zig-zag is suitable for firm fabrics like

denim, corduroy, etc.

1

2

0

1

2

3

4

S

S

0

1

2

3

4

S

S

0

5

0

1

2

3

4

3~5

5

0

1

2

3

4

A B

La página se está cargando...

GB

62

Smocking stitch

Seams, hems, T-shirts, underwear, etc.

Set the machine as illustrated.

This stitch can be used for all types of jersey as well as for woven

fabrics. (1)

Sew at 1 cm (1/4") from the fabric edge and trim the surplus fabric.

(2)

Pattern selector on "E".

Turn the stitch length dial to "S".

1

2

0

1

2

3

4

S

S

4~5

5

0

1

2

3

4

E

La página se está cargando...

GB

64

Sewing with the cording foot

Decorative effects, cushions, tablecloths, etc.

Set the machine as illustrated. Various stitches are suitable for

sewing on cord, e.g. Zig-zag, Triple zig-zag, decorative stitches.

Insert the cord between the spring covering the cord groove and

the foot. The cord should run in the groove. One, two or three

cords can be sewn on. The stitch width is adjusted according to

the number of cords and the stitch selected. (1/2)

0

1

2

3

4

S

1~4

3~5

5

0

1

2

3

4

B

1

2

La página se está cargando...

GB

66

Free motion darning

Set the machine as illustrated. Move the drop feed control to right

side to lower the feed dogs. (1)

Remove the presser foot clamp. (2)

Attach the darning foot to the presser foot bar. The lever (A)

should be behind the needle clamp screw (B). Press the darning

foot on firmly from behind with your index finger and tighten the

screw (C). (3)

First sew round the edge of the hole (to secure the threads). (4)

First row: Always work from left to right. Turn work by 1/4 and

oversew.

A darning ring is recommended for easier sewing and better

results.

0

1

2

3

4

S

0

0

5

0

1

2

3

4

A

1

a

b

A

B

C

2

3

4

a

b

La página se está cargando...

GB

68

Practical stitches

1

2 3

F PI

0

1

2

3

4

S

1~2

3~5

5

0

1

2

3

4

Set the machine as illustrated.

Turn the stitch width dial and stitch length dial to suit the fabric.

Feather stitch (1)

Rampart (2)

Shell hem (3)

Pattern selector on "F".

Pattern selector on "I".

For flat joining seams, sewing on elastic, visible hems.

This stitch can be used for firm, thicker fabrics.

Pattern selector on "P".

For decorative edges.

Suitable for edges on sheer, fine and stretch fabrics. The larger

stitch should go just over the edge of the fabric to create the shell

effect.

For decorative joining seam for a fagoted effect.

La página se está cargando...

GB

70

Darning

- Turn stitch length dial to the desired length.

- Turn stitch selector to straight stitch, center needle position.

- Position the fabric to be darned under the presser foot together

with the under laying fabric to be used.

- Lower the presser foot and alternately sew forward or reverse

using the lever.

- Repeat this motion until the area to be darned is filled with rows

of stitching.

For reverse sewing instructions, see page 32.

Darning

0

1

2

3

4

S

2~4

0

5

0

1

2

3

4

A

F

E

- Gire el disco regulador del largo de puntada al largo deseado.

- Gire el selector a costura recta, posición central de la aguja.

- Coloque la tela a zurcir bajo el prensatelas, junto con la tela subyacente que se va a

utilizar.

- Baje el pié prénsatela y de manera alternativa, cosa hacia delante y atrás accionando

la palanca reversora.

- Repita este movimiento hasta que la parte a zurcir se rellene con hileras de cosido.

Para las instrucciones sobre cómo coser hacia atrás, vea página 33.

Zurcido

- Régler la longueur du point selon la longueur désirée.

- Placer le sélecteur de points à la couture droite, position d'aiguille au centre.

- Faufiler une pièce de renfort sous la section à repriser et placer le tissu sous le pied-

de-biche.

- Abaisser le pied-de-biche et coudre alternativement en marche avant et en marche

arrière en vous servant du levier de marche arrière.

- Répéter ce mouvement jusqu'à ce que toute la surface à repriser soit couverte.

Pour les instructions de marche arrière. Voir P. 33.

71

Reprisage

GB

72

Attaching lace

- Turn stitch length dial to the desired length.

- Turn the stitch selector to straight stitch, center needle position.

- Fold in the edge of the fabric (approximately 6 mm 1/4").

- Place the lace under the folded edge of the fabric allowing it to

under lap the fabric slightly as required by the pattern of the lace.

- Sew on the edge of the fabric fold.

- You can add a decorative touch by using the satin stitch to sew

the lace.

Attaching lace

0

1

2

3

4

S

2~4

0

5

0

1

2

3

4

A

La página se está cargando...

GB

74

Applique

- Turn stitch length dial to the desired length.

- Turn pattern selector dial to zig zag.

- Select a narrow zig zag width.

- Cut out the applique design and baste it to the fabric.

- Sew slowly around the edge of the design.

- Trim excess material outside the stitching. Make sure not to cut

any stitches.

- Remove the basting thread.

- Tie top and bottom thread under the applique to avoid

unraveling.

0

1

2

3

4

S

0.5~1

3~5

5

0

1

2

3

4

B

F

E

- Regular la máquina segúina segun la ilústración.

- Reducir el ancho de la puntada de zigzag.

1. Hilvane el diseño sobre la superficie de la tela.

2. Empieze a coser con cuidado según el diseño.

3. Recorte la tela que rebase la costura.

4. Saque la puntadas de hilvanar.

Nota:

Vuelva a coser las puntadas finales e inciales con puntada recta para reforzar.

Aplicación

- Régler le bouton de longueur de point selon la longueur désirée.

- Placer le sélecteur de point à un point de zigzag étroit.

- Découper l'appliqué et le faufiler au vêtement.

- Coudre lentement près du bord extérieur de l'appliqué.

- Recouper tout excédent de tissu en prenant soin de ne couper aucun des points

cousus.

- Retirer le faufil.

- Tirer le fil à l'envers du tissu et attacher ensemble.

75

Appliqué

GB

76

Twin needle

* The twin needle is an optional accessory not supplied with your

machine.

- Turn stitch length dial to the desired stitch length.

- Turn stitch selector to straight stitch, center needle position,

width setting "0".

- Make sure that the two threads used to thread the twin needle

are of the same weight. You can use one or two colors.

- Insert the twin needle in the same way as single needle. Flat

side of needle should face away from you.

- Follow instructions for single needle threading. Thread each

needle separately.

Please note:

When sewing with twin needle, always proceed slowly, and make

sure to maintain a low speed to insure quality stitching.

When using twin needle on zig-zag make sure the stitch width dial

is set between "0" and "2.5". Do not use twin needle at setting

above "2.5".

0

1

2

3

4

S

1~4

0~2.5

5

0

1

2

3

4

A

La página se está cargando...

GB

78

0

1

2

3

4

S

0

1~5

5

0

1

2

3

4

- Set the machine as illustrated.

- Remove the presser foot and the presser foot holder.

- Move the drop feed control to right side to lower the feed dogs.

(1)

- Lower presser foot lever before starting to sew.

- Adjust the stitch width according to the size of lettering or design.

- Draw the desired lettering or design on the right side of the

fabric.

- Stretch the fabric between embroidery hoop as firmly as

possible.

- Place the fabric under the needle. Make sure the presser foot

bar is down in its lowest position.

- Turn the balance wheel towards you to bring up the lower thread

through the fabric. Sew a few securing stitches at the starting

point.

- Hold the hoop with thumb and forefingers of both hands while

pressing the material with the middle and third fingers and

supporting the outside of hoop with smaller finger.

* Embroidery hoop not included with machine.

Preparation for Monogramming and Embroidering*

Monogramming and embroidering with embroidery hoop*

B

2

1

a

b

a

b

La página se está cargando...

GB

80

Quilting

Set pattern selector as illustrated.

Insert the quilting guide in presser foot holder and set the space

as you desired.

Move the fabric over and sew successive rows with the guide

riding along on the previous row of stitching.

Note:

Presser foot shown is the optional quilting foot which does not

come with your machine. If you have not purchased this foot

substitute the all purpose foot.

0

1

2

3

4

S

1~4

0

5

0

1

2

3

4

A

La página se está cargando...

GB

82

Gathering

Set the pattern selector as illustrated.

1. Attach the gathering foot.

2. Sew a single row or multiple rows of straight stitches.

3. If more gathering is required, loosen the upper thread tension

to below 2 so that the lower thread lies on the under side of the

material.

4. Pull the lower thread to gather more of the material.

Note:

Presser foot shown is the optional gathering foot which does not

come with your machine. If you have not purchased this foot

substitute the all purpose foot and gather fabric by hand by

lowering the tension setting to below 2 and pulling the lower

thread to gather the material.

0

1

2

3

4

S

1~4

0

5

0

1

2

3

4

A

La página se está cargando...

GB

84

0

1

2

3

4

S

1~2

5

0

1

2

3

4

N

This machine automatically produces a scallop stitch which may

be used as decorative edging.

- Set the pattern selector at "N".

- Sew the scallop stitch along the edge of the material. (1)

- If desired, trim around the scallop with scissors to create a

scalloped edge. Be careful not to cut the thread. (2)

3~5

Scallop stitching

1

2

La página se está cargando...

GB

86

Patch work

These stitches are used to join two pieces of fabric while leaving a

space between their edges.

1. Fold over the edges of the two pieces of fabric for the hem and

baste the edges to a thin piece of paper leaving a small space

between them.

2. Set the Pattern selector on "I".

Turn the stitch length dial to "S".

3. Stitch along the edge, pulling both threads slightly when begin-

ning to sew.

* Use thicker than normal threads for sewing.

4. After sewing, remove the basting and the paper. Finish by tying

knots on the reverse side at the beginning and the end of the

seams.

0

1

2

3

4

S

S

3~5

5

0

1

2

3

4

I

La página se está cargando...

88

GB

The walking foot accessory

c

a

d

a

b

1

2

3

e

f

Always try to sew first without the walking foot accessory

which should be used only when necessary.

It is easier to guide the fabric and you have a better view of

the seam when using the standard, regular foot on your

machine. Your EURO-PRO sewing machine offers excellent

stitch quality on a wide range of fabrics from delicate

chiffons to multiple layers of denim.

The "Walking foot" accessory equalizes the feeding of the

upper and lower layers of fabric and improves the matching

of plaids, stripes and patterns. This foot helps to prevent

uneven feeding of very difficult fabrics.

1. Lift the presser foot bar.

2. Remove the "foot holder" by opening counter clockwise

the presser bar attaching screw. (3)

3. Attach the "walking foot" to the machine in the following

way.

i) The fork arm should fit into the needle screw and

clamp. (2)

ii) Slide the plastic "attaching head" from your left to right

so that it is fitted into the "presser foot bar".

iii) Lower the "presser foot bar".

iv) Replace and tighten clockwise the "presser bar

attaching screw".

4. Make sure both the "needle screw" and the "presser bar

attaching screw" are tightly secured.

5. Draw the bobbin thread up and place both the bobbin

thread and the needle thread behind the walking foot

attachment.

a. Fork arm

b. Attaching head

c. Needle bar

d. Needle screw & clamp

e. Presser foot bar

f. Presser bar attaching screw

La página se está cargando...

Adjust the stitch length according to the stitch selected.

However, the stitch width must be set at maximum.

Note: The side cutter can only be used with

the regular zigzag stitch (at maximum width

)

or the overlock stitches.

La página se está cargando...

GB

2

Caution:

Always make sure that the machine is unplugged

from power source and the main switch is on "O"

before inserting or removing any parts and before

cleaning.

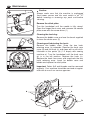

Remove the stitch plate:

Cleaning the feed dog:

Cleaning and lubricating the hook:

Important:

Turn the handwheel until the needle is fully raised.

Open the hinged front cover and unscrew the needle

plate screw with the screw driver. (1)

Remove the bobbin case and use the brush supplied

to clean the whole area. (2)

Remove the bobbin case. Snap the two hook

retaining arms (a) outwards. Remove the hook race

cover (b) and the hook (c) and clean with a soft cloth.

Lubricate at the points (d) (1-2 drops) with sewing

machine oil. Turn the handwheel until the hook race

(e) is in the left position. Replace the hook (c).

Replace the hook race cover and snap back the two

hook retaining arms. Insert he bobbin case and

bobbin and replace the stitch plate.

Fabric fluff and threads must be removed

regularly. Your machine should be serviced at regular

intervals at one of our service agencies.

Maintenance

a

b

c

d

e

1

92

La página se está cargando...

Problem Cause Correction

Upper thread

breaks

Lower thread

breaks

Skipped stitches

Needle breaks

Loose stitches

Seams gather

or pucker

Uneven stitches,

uneven feed

The machine is

noisy

The machine

jams

1.The machine is not threaded

correctly

2.The thread tension is too tight

3.The thread is too thick for the needle

4.The needle is not inserted correctly

5.The thread is round wound the

spool holder pin

6.The needle is damaged

1.The bobbin case is not inserted

correctly

2.The bobbin case is threaded wrongly

3.The lower thread tension is too tight

1.The needle is not inserted correctly

2.The needle is damaged

3.The wrong size needle has been

used

4.The foot is not attached correctly

1.The needle is damaged

2.The needle is not correctly inserted

3.Wrong needle size for the fabric

4.The wrong foot is attached

1.The machine is not correctly

threaded

2.The bobbin case is not correctly

threaded

3.Needle/ fabric/ thread combination is

wrong

4.Thread tension wrong

1.The needle is too thick for the fabric

2.The stitch length is wrongly adjusted

3.The thread tension is too tight

1.Poor quality thread

2.The bobbin case is wrongly

threaded

3.Fabric has been pulled

1.The machine must be lubricated

2.Fluff or oil have collected on the hook

or needle bar

3.Poor quality oil has been used

4.The needle is damaged

Thread is caught in the hook

1.Rethread the machine

2.Reduce the thread tension (lower number)

3.Select a larger needle

4.Remove and reinsert the needle (flat side

towards the back)

5.Remove the reel and wind thread onto reel

6.Replace the needle

1.Remove and reinsert the bobbin case and

pull on the thread. The thread should pull

easily

2.Check both bobbin and bobbin case

3.Loosen lower thread tension as described

1.Remove and reinsert needle (flat side

towards the back)

2.Insert a new needle

3.Choose a needle to suit the thread and

fabric

4.Check and attach correctly

1.Insert a new needle

2.Insert the needle correctly (flat side towards

the back)

3.Choose a needle to suit the thread and

fabric

4.Select the correct foot

1.Check the threading

2.Thread the bobbin case as illustrated

3.The needle size must suit the fabric and

thread

4.Correct the thread tension

1.Select a finer needle

2.Readjust the stitch length

3.Loosen the thread tension

1.Select a better quality thread

2.Remove bobbin case and retread and

insert correctly

3.Do not pull on the fabric while sewing, let it

be taken up by the machine

1.Lubricate as described

2.Clean the hook and feed dog as described

3.Only use good quality sewing machine oil

4.Replace the needle

Remove the upper thread and bobbin case,

turn the handwheel backwards and forwards

by hand and remove the thread remands.

Lubricate as described

Trouble shooting guide

GB

94

La página se está cargando...

F

Comment remédier soi-même aux petits problèmes

F

Problème Cause Remède

Le fil supérieur

casse

Le fil inférieur

casse

Les points ne

se forment pas

toujours

L'aiguille casse

Des noeuds se

forment au cours

du travail

Les coutures se

rétractent ou se

froncent

Les points et

l'entraînement

sont irréguliers

La machine est

bruyante

La machine est

bloquée

1. L'enfilage du fil est incorrect.

2. La tension du fil est trop forte.

3. Le fil est trop épais pour l'aiguille.

4.

5. Le fil s'est entortillé sur la broche de

la bobine.

6. L'aiguille est endommagée.

1. La boîte à canette n'est pas placée

correctement.

2. La boîte à canette n'est pas enfilée

correctement.

3. La tension du fil est trop forte.

2. L'aiguille est tordue ou épointée.

3. L'aiguille n'a pas la classe ou la

grosseur correcte.

4. Le pied-de-biche ne convient pas.

1. L'aiguille est tordue ou épointée.

2. La boîte à canette n'est pas enfilée

correctement.

3. Tissu trop épais/ grosseur incorrecte

de l'aiguille.

4. Le pied-de-biche ne convient pas.

1. Le fil n'est pas enfilé correctement.

2. La boîte à canette n'est pas enfilée

correctement.

3. Le rapport aiguille/ tissu/ fil est incorrect.

4. Le fil n'est pas tendu correctement.

1. L'aiguille est trop grosse pour le tissu.

2. La tension du fil est trop forte.

1. Le fil n'est pas assez solide.

2. La boîte à canette n'est pas enfilée

correctement.

3. Le tissu est tiré lors du piquage.

1. La machine doit être lubrifiée.

2. Présence de bourre ou de trace

d'huile sur le cro-chet ou sur la barre

d'aiguille.

3. L'huilage a été effectué avec une

huile de mauvaise qualité.

4. L'aiguille est tordue ou épointée.

Le fil est coincé dans le crochet.

1. Enfiler à nouveau le fil à travers la machine

et l'aiguille

2. Réduire la tension du fil supérieur (chiffre

inférieur)

3. Utiliser une aiguille plus grosse

4. Enlever l'aiguille , puis la remettre en place

(talon dirigé vers l'arrière)

5. Retirer la bobine et bobiner le fil

6. Remplacer l'aiguille

1. Enlever la navette, puis la remettre en place

et tirer sur le fil. Si le fil se déroule facilement,

la navette est bien en place.

2. Contrôler la canette et la navette

3. Rectifier la tension du fil inférieur de la

manière prescrite

1. Enlever l'aiguille puis la remettre en place

(talon dirigé vers l'arrière).

2. Remplacer l'aiguille.

3. Choisir une aiguille dont la grosseur est

adaptée au fil et à l'étoffe.

4. Vérifier si le pied-de-biche utilisé convient

pour l'ouvrage.

1. Remplacer l'aiguille .

2. Enlever l'aiguille, puis la remettre en place

(talon dirigé vers l'arrière).

3. Choisir une aiguille dont la grosseur est

adaptée au fil et au tissu.

4. Changer le pied-de-biche.

1. Enfiler correctement le fil dans la machine.

2. Enfiler la navette de la manière prescrite.

3. Choisir une aiguille dont la grosseur est

adaptée au fil et à l'étoffe.

4. Rectifier la tension du fil.

1. Utiliser une aiguille plus fine.

2. Rectifier la tension du fil.

1. Utiliser un fil de meilleur qualité.

2. Enfiler à nouveau la boîte à canette, puis la

remettre en place.

3. Ne pas tirer le tissu lors de la couture. Celui-

ci doit être entraîné automatiquement.

1. Huiler la machine en suivant les instructions

2. Nettoyer le crochet et la griffe d'entraînement

en suivant les instructions.

3. Pour le huilage, utiliser exclusivement une

huile spéciale pour machine à coudre.

4. Remplacer l'aiguille.

Enlever le fil supérieur et la navette, tourner le

volant par secousses à la main en avant et en

arrière. Enlever les restes de fil. Huiler selon

les instructions.

L'aiguille n'est pas insérée correctement.

1. L'aiguille n'est pas insérée correctement.

96

La página se está cargando...

Transcripción de documentos