Land Rover L322 Range Rover Workshop Manual

- Categoría

- Carros

- Tipo

- Workshop Manual

Este manual también es adecuado para

Workshop Manual

System Description & Operation

NRRWM 21/11/01 11:21 am Page 1

2002MY

WORKSHOP MANUAL - SYSTEM

DESCRIPTION AND OPERATION

LRL0424ENG (2nd Edition)

Published by Land Rover – Technical Service

© 2002 Land Rover

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form,

electronic, mechanical, recording or other means without written prior permission from Land Rover.

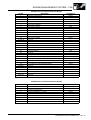

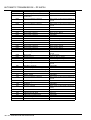

CONTENTS

CONTENTS 1

ENGINE – Td6 12-1-1

Td 6 – External View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1-2

ENGINE - V8 12-2-1

V8 – External View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-2-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2-2

ENGINE MANAGEMENT SYSTEM – Td6 18-1-1

Engine Management Component Location – Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-1-2

Engine Management Component Location – Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-1-4

Engine Management Control Diagram – Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1-6

Engine Management Control Diagram – Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1-8

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1-10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1-35

Cruise Control Component Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-1-39

Cruise Control, Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-1-40

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1-42

ENGINE MANAGEMENT SYSTEM – V8 18-2-1

Engine Management Component Location – Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-2-2

Engine Management Component Location – Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-2-4

Engine Management Control Diagram – Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-2-6

Engine Management Control Diagram – Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-2-8

Bosch ME 7.2 Engine Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-2-10

Variable Camshaft Control Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-2-41

VCC System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-2-42

Cruise Control Component Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-2-50

Cruise Control System Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-2-51

Cruise Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-2-53

EVAP System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-2-55

Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-2-56

FUEL DELIVERY SYSTEM – Td6 19-1-1

Td6 Fuel Delivery Component Location – Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-1-1

Td6 Fuel Delivery Component Location – Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-1-2

Td6 Fuel System Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-1-4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-1-6

FUEL DELIVERY SYSTEM – V8 19-2-1

Fuel Delivery System Component Location (All Except NAS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-2-2

Fuel Delivery System Component Location (NAS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-2-4

V8 Fuel Delivery System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-2-6

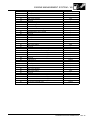

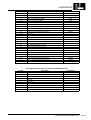

CONTENTS

2CONTENTS

COOLING SYSTEM – Td6 26-1-1

Td6 Cooling System – Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-1-2

Td6 Cooling System – Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-1-4

Td6 Coolant Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-1-6

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-1-8

COOLING SYSTEM – V8 26-2-1

V8 Cooling System – Sheet 1 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-2-2

V8 Cooling System – Sheet 2 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-2-4

V8 Coolant Flow – Models With FBH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-2-6

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-2-8

MANIFOLDS AND EXHAUST SYSTEM – Td6 30-1-1

Exhaust Manifold Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-1-2

Inlet Manifold Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-1-4

Exhaust System Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-1-6

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-1-8

MANIFOLDS AND EXHAUST SYSTEM – V8 26-2-1

Exhaust Manifold Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-2-1

Inlet Manifold Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-2-2

Exhaust System Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-2-4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-2-6

TRANSFER BOX 41-1

Transfer Box Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41-1

Transfer Box Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41-2

Transfer Box Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41-4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41-6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41-20

AUTOMATIC TRANSMISSION – GM 5L40-E 44-1-1

GM 5L40-E Automatic Transmission Component Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44-1-2

GM 5L40-E Automatic Transmission – Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44-1-4

GM 5L40-E Automatic Transmission – Sectional View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44-1-6

GM 5L40-E Automatic Transmission – Valve Block and Solenoid Valves . . . . . . . . . . . . . . . . . . 44-1-8

GM 5L40-E Automatic Transmission – Fluid Pump Cover Plate Assembly . . . . . . . . . . . . . . . . . 44-1-10

GM 5L40-E Automatic Transmission Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44-1-12

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44-1-14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44-1-58

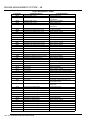

CONTENTS

CONTENTS 3

AUTOMATIC TRANSMISSION – ZF 5HP24 44-2-1

ZF 5HP24 Automatic Transmission Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44-2-2

ZF 5HP24 Automatic Transmission – Exploded View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44-2-4

ZF 5HP24 Automatic Transmission – Sectional View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44-2-6

ZF 5HP24 Automatic Transmission – Valve Block and Solenoid Valves . . . . . . . . . . . . . . . . . . . . 44-2-8

ZF 5HP24 Automatic Transmission Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44-2-10

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44-2-12

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44-2-50

DRIVE AND PROPELLER SHAFTS 47-1

Drive and Propeller Shafts – Component Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47-2

FINAL DRIVE 51-1

Differentials – Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51-2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51-10

STEERING 57-1

Steering Component Location – Td6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57-1

Steering Component Location – V8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57-2

Steering Control Diagram – Servotronic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57-3

Steering Control Diagram – Column Adjustment – Without Memory . . . . . . . . . . . . . . . . . . . . . . . 57-4

Steering Control Diagram – Column Adjustment – With Memory. . . . . . . . . . . . . . . . . . . . . . . . . .57-5

Steering Control Diagram – Column Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57-6

Steering Control Diagram – Steering Wheel Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57-8

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57-9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57-22

SUSPENSION 60-1

Suspension Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60-1

Suspension Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60-2

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60-3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60-27

BRAKES 70-1

Braking System Component Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70-2

Front Brake Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70-4

Rear Brake Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70-5

Foundation Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70-6

Dynamic Stability Control System Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70-12

Dynamic Stability Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70-14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70-26

Hand Brake Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70-32

Hand Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70-34

CONTENTS

4CONTENTS

RESTRAINT SYSTEMS 75-1

Front Seat Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75-1

Rear Seat Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75-2

SRS Component Layout – Sheet 1 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75-3

SRS Component Layout – Sheet 2 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75-4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75-5

SRS Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75-18

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75-20

DOORS 76-1-1

Front Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-1-1

Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-1-2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-1-10

INTERIOR TRIM COMPONENTS 76-3-1

Interior Mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-3-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-3-2

SEATS 76-5-1

Front Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-5-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-5-2

Seat Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-5-8

SUNROOF 76-6-1

Sunroof Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-6-1

Sunroof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-6-2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76-6-3

AIR CONDITIONING 82-1

Refrigerant System Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-1

Heater Assembly and Ducting Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-2

Control System Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-4

FBH System Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-5

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-6

A/C Control Diagram – Low Line System, Sheet 1 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-32

A/C Control Diagram – Low Line System, Sheet 2 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-34

A/C Control Diagram – High Line System, Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-36

A/C Control Diagram – High Line System, Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-38

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82-40

WIPERS AND WASHERS 84-1

Wiper and Washer System Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84-2

Wipers and Washers Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84-4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84-6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84-18

CONTENTS

CONTENTS 5

CHARGING AND STARTING 86-1-1

Charging and Starting Component Location – Td6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-1-1

Charging and Starting Component Location – V8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-1-2

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-1-3

LIGHTING 86-2-1

Exterior Lighting Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-2-2

Exterior Lighting Control Diagram – Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-2-4

Exterior Lighting Control Diagram – Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-2-6

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-2-8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-2-27

Interior Lighting Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-2-32

Interior Lighting Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-2-34

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-2-36

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-2-38

BODY CONTROL UNIT 86-3-1

BCU Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-3-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-3-2

COMMUNICATION DATA BUSES 86-4-1

Communication Data Buses Control Diagram – Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-4-2

Communication Data Buses Control Diagram – Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-4-4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-4-6

SECURITY 86-5-1

Locking and Alarm Component Layout – Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-5-1

Locking and Alarm Component Layout – Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-5-2

Immobilisation Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-5-3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-5-4

Alarm and Locking Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-5-16

Immobilisation Control Diagram – Diesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-5-18

Immobilisation Control Diagram – Petrol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-5-19

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-5-20

WINDOWS 86-6-1

Windows Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86-6-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-6-2

Windows Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-6-6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-6-8

CONTENTS

6CONTENTS

ENTERTAINMENT AND INFORMATION SYSTEMS 86-8-1

MID Audio System Component Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-2

MID Audio System Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-4

Multi-Function Display Audio Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-6

Multi-Function Display Audio Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-8

Screen Aerial Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-10

Speaker System Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-11

Base Speaker Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-12

Power Amplifier Speaker System Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-14

DSP Amplifier Speaker System Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-16

Audio Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-18

Navigation System Component Location (Except Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-37

Navigation System Control Diagram (Except Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-38

Navigation System Component Location (Japan Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-40

Navigation System Control Diagram (Japan Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-42

New Range Rover Navigation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-44

Telephone System Component Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-55

Telephone System Control Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-56

Telecommunication System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-58

Voice Recognition System Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-8-63

DRIVING AIDS 86-10-1

Park Distance Control Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-10-1

PDC Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-10-2

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-10-3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-10-6

Tyre Pressure Monitoring Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-10-8

TPM Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-10-10

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-10-12

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86-10-15

INSTRUMENTS 88-1

Instrument Pack – Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88-1

Instrument Pack – Front View – NAS Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88-2

Instrument Pack – Control Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88-4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88-6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88-31

ENGINE – TD6

DESCRIPTION AND OPERATION 12-1-1

ENGINE – Td 6DESCRIPTION AND OPERATION

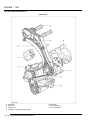

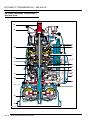

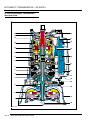

Td 6 – External View

M12 7758A

ENGINE – TD6

12-1-2 DESCRIPTION AND OPERATION

Description

General

The Td6 diesel engine is a 3.0 litre, 6 cylinder, in-line direct injection unit, with 4 valves per cylinder, operated by two

overhead camshafts. The engine emissions comply with ECD3 (European Commission Directive) legislative

requirements and employs a catalytic converter, electronic engine management control, positive crankcase

ventilation and exhaust gas recirculation to limit the emission of pollutants. The unit is water cooled and turbo-

charged. The fuel injection system features common rail technology.

The cylinder block is of cast iron construction with a cast aluminium stiffening plate bolted to the bottom of the block

to improve lower structure rigidity. The cylinder head is cast aluminium with a moulded plastic camshaft cover. The

single-piece oil sump is also cast aluminium. The exhaust manifold is mounted on the right side of the engine and a

moulded plastic acoustic cover is fitted over the upper engine to reduce engine generated noise.

To reduce the level of transmitted engine vibration to the vehicle body, the engine is mounted on two hydraulically

damped mountings, fitted between the engine support brackets and engine sub-frame. These are controlled by the

Engine Control Module (ECM).

+ ENGINE MANAGEMENT SYSTEM – Td6, DESCRIPTION AND OPERATION, Description.

Technical Features

The technical features include:

l In-line 6–cylinder engine with a cast iron crankcase

l Plastic cylinder head cover

l Light alloy cylinder head

l 4-valve technology with centrally arranged fuel injector

l Valves and springs identical to the Td4

l Plastic manifold based on two-shell weld technology

l Exhaust turbocharger, with Variable Nozzle Turbine (VNT)

l Compression ratio 18:1

l Common rail fuel injection system

l High pressure fuel pump

l Cooling duct pistons with central crown bowl

l Electronically controlled Exhaust Gas Recirculation (EGR)

l Exhaust re-treatment by means of a diesel specific oxidation catalytic converter and primary catalytic converter

l Switchable hydraulic engine mounts

l 7-blade cooling fan with viscous clutch drive

l Engine cut out begins at 4000 rpm. The cutout limit is reached at approx. 4800 rpm.

Engine Data

The technical data is detailed below.

DESCRIPTION TYPE

Engine type/valves R6/4

Displacement (eff.) 2926 ccm

Stroke/bore 88.0/84.0 mm

Compression ratio 18 : 1

Firing order 1, 5, 3, 6, 2, 4

Engine weight 210 kg

Power to weight ratio 1.56 kg/kW

Total oil capacity (including

filter)

8.8 litres

ENGINE – TD6

DESCRIPTION AND OPERATION 12-1-3

Cylinder Block Components

The cylinder block components are described below:

Cylinder Block

The cylinders and crankcase are contained in the cylinder block, which is of single grey cast iron construction with

hollow beam structure. The cylinders are direct bored. Oil is supplied via lubrication jets for piston and gudgeon pin

lubrication and cooling.

Lubrication oil is distributed throughout the block via the main oil gallery to critical moving parts through channels

bored in the block which divert oil to the main bearings, and to the big-end bearings via holes machined into the

crankshaft.

A tapping at the front RH side of the cylinder block connects a pipe to the turbocharger by means of a banjo

connection. Oil under pressure from the oil pump provides lubrication for the turbocharger bearings.

Cylinder cooling is achieved by coolant circulating through chambers in the engine block casting.

NOTE: The water jacket does not have core plugs.

Two hollow metal dowels are used to locate the cylinder block to the cylinder head, one on each side at the front of

the unit. Two additional hollow metal dowels are used to locate the timing cover to the cylinder block.

A port is included at the rear right hand side of the cylinder block which connects to the turbocharger oil drain pipe to

return lubrication oil to the sump.

A plug sealing the lubrication cross-drilling gallery is located at the front right hand side of the cylinder block. Plugs

for the main lubrication gallery are included at the front and rear of the cylinder block.

Connecting Rods

The connecting rods are machined, H-sectioned steel forgings. The big-end bearing shells are plain split halves. The

upper half of the bearing shell is treated using the sputtering process (cathodic surface coating process) to improve

its resistance to wear.

The small-end of the connecting rod has a bushed solid eye which is free to move on the gudgeon pin. The small-end

bush is a hand-push transition fit.

ENGINE – TD6

12-1-4 DESCRIPTION AND OPERATION

Connecting Rod and Piston

Pistons

The six pistons are gravity die cast with graphite-compound coated aluminium alloy skirts. Although the piston is

similar to that fitted to the Td4 engine the lobe in the piston crown bowl is higher.

The combustion chamber is designed on a swirl chamber principle.

The swirl chamber partly contains the inlet air during the combustion process and helps provide turbulence for efficient

air/fuel mixture to promote complete combustion. This reduces fuel consumption, exhaust emission and smoke

produced at full load. The four recesses in the piston's crown also provide clearance for the valve heads.

The pistons are attached to the small-end of the connecting rods by fully floating gudgeon pins which are retained in

the piston by circlips.

The pistons incorporate an oil cooling channel for piston and gudgeon pin cooling, oil being supplied under pressure

from the piston lubrication jets.

Piston Rings

Each piston is fitted with two compression rings and an oil control ring. The top compression ring is located in a steel

insert ring carrier which helps to provide a minimal reaction to compression forces.

The top ring is a 10° chromium-plated keystone ring. The 2nd compression ring is a tapered compression ring and

the lower ring is a chromium-plated spring loaded bevelled ring.

Piston Lubrication Jets

The six lubrication jets (one for each cylinder) have a long hook-type nozzle and are fitted at the bottom right hand

side of each cylinder.

The jets provide lubrication to the cylinder walls, and to the piston underskirt for cooling the pistons and lubricating

the gudgeon pins and small-end bearings. The input port to each lubrication jet mates with a port provided in each

mounting position, tapped at the underside of the cylinder block from a main gallery on the RH side of the block.

ENGINE – TD6

DESCRIPTION AND OPERATION 12-1-5

Integrated Oil Cooler and Filter Assembly

1 Sealing gasket

2 Filter housing

3 Filter element

4 O-ring seal – cap

5 O-ring seal (2 off)

6 Filter cap

7 Heat exchanger

8 Heat exchanger to filter housing attachment

bolt (Torx –3 off)

9 Heat exchanger to filter housing gasket

10 Oil pressure switch

11 Filter housing to engine block attachment bolts

– 3 off

The combined engine oil cooler and filter assembly, mounted to the left side of the engine block, is connected to the

vehicle cooling and lubrication systems. The disposable paper filter element is replaced by unscrewing the cover from

the filter housing.

The oil filter housing has an integral thermostatic valve which controls the amount of oil flowing through the oil cooler,

dependent on the oil temperature.

Oil from the cylinder block passes through the oil filter housing and partial flow is directed through the oil cooler before

it is returned to the cylinder block. The coolant for the heat exchanger is supplied directly from the crankcase.

The oil pressure switch, operating a warning lamp in the instrument pack, is fitted to the oil filter housing.

Oil Pressure Switch

The oil pressure switch is located in a port in the oil filter housing. If the oil pressure drops below a given value the

switch operates the warning lamp in the instrument pack

ENGINE – TD6

12-1-6 DESCRIPTION AND OPERATION

High Pressure Fuel Pump

The high pressure fuel pump supplies fuel to the fuel rail and is fixed to a flange on the front LH side of the cylinder

block. The pump is a 3 radial piston type controlled by the EDC engine management system and chain driven from

the crankshaft at 0.75 times engine speed.

+ ENGINE MANAGEMENT SYSTEM – Td6, DESCRIPTION AND OPERATION, Description.

Crankshaft Position (CKP) Sensor

The crankshaft position (CKP) sensor is mounted on the rear LH side of the cylinder block. The sensor is an inductive

type which acts on a reluctor on the flywheel.

+ ENGINE MANAGEMENT SYSTEM – Td6, DESCRIPTION AND OPERATION, Description.

Crankshaft and Sump Components

The crankshaft and sump and oil pump components are described below:

Crankshaft

Crankshaft Drive

Arrow denotes front of engine.

1 No 1 Piston

2 No 6 Piston

3 Incremental wheel

The crankshaft is manufactured from high tensile steel. The bearing surfaces and radii are inductively hardened for

toughness and fatigue resistance. It is supported on 7 main bearings with a flanged thrust bearing located between

No 5 and No 6 cylinders. Dynamic balancing is achieved by the use of twelve balance weights.

Cross-drillings in the crankshaft between the adjoining main and big-end bearings are used to divert the lubrication

oil to the big-end bearings.

ENGINE – TD6

DESCRIPTION AND OPERATION 12-1-7

Crankshafts are available in three sizes:

l Standard

l Undersize 1

l Undersize 2.

Colour coding identifies the size of the journal.

At the front of the crankshaft is a four-hole threaded connection, used to attach the axially vibration damper and

cooling fan. The engine RPM signal is taken from the reluctor “target” attached to the crankshaft.

The crankshaft oil seals are manufactured from PTFE.

Main Bearings

The main crankshaft bearing shells have oil grooves and a drilling in the upper bearing shell, to provide oil via the

crankshaft drillings to the connecting rod big-end bearings.

Sump

The one-piece aluminium die-cast sump, with an integral tunnel for the differential drive shaft, is sealed to the lower

crankcase extension using a rubber metal-backed gasket. The sump is fixed to the lower crankcase extension using

25 bolts. An oil deflector plate is attached to the crankcase reinforcing shell above the sump.

Oil Pump

The oil pump assembly is bolted to the bottom of the cylinder block and is located in front of the engine block stiffener

plate. The pump is an internal gear-type with sintered rotors and is driven through a chain and sprocket system from

the crankshaft.

A pressure relief valve is included at the outlet side of the oil pump to control oil pressure at high engine speeds by

recirculating oil through the relief valve back around the pump to the inlet. The relief valve and spring is a plunger type;

when oil pressure is great enough to lift the plunger, oil is allowed to escape past the plunger to relieve pressure and

prevent any further rise in pressure.

Oil is delivered to the pump from the pick-up pipe, and the outlet side of the oil pump delivers pressurised oil flow to

the engine block main oil delivery gallery.

Flywheel

Located between the engine and transmission the flywheel is of sheet metal laminated construction.

ENGINE – TD6

12-1-8 DESCRIPTION AND OPERATION

Camshaft Timing Components

Chain Drive

1 Camshaft

2 Guide rail

3 Crankshaft

4 Common rail high pressure pump

5 Oil pump

6 Tensioning rail

7 Chain tensioner

ENGINE – TD6

DESCRIPTION AND OPERATION 12-1-9

The camshaft timing components are described below:

Timing Case Cover

The timing chain cover is cast and machined aluminium alloy and is bolted to the cylinder block. Five bolts are used

to fix the upper flange of the timing cover to the cylinder head casting, and a further four bolts secure the front of the

sump to the timing cover. The bottom of the timing cover is located to the front face of the cylinder block by two metal

dowels.

The front of the crankshaft passes through a hole in the timing cover, and a replaceable beaded gasket is used to seal

the interface between the front of the crankshaft and the timing cover.

The ancillary components and belt pulley attachments are fitted to the front cover.

Chain Drive

Two timing chain drives are used. The timing chain between the crankshaft sprocket and the fuel injection pump

sprocket is a simplex type. The timing chain is contained between one fixed and one hydraulically adjustable

tensioning rail.

The chain drive from the fuel injection pump sprocket to the two camshaft sprockets is also a simplex type. The chain

runs between one fixed guide rail and a hydraulically adjustable tensioning rail to minimise chain flutter. An additional

plastic chain guide is located above the two camshaft sprockets.

The adjustable tensioning rails are of aluminium die casting construction with clip-fastened plastic slide linings. The

fixed guide rails are moulded plastic. The tensioner rails are attached to the front of the cylinder blocks using pivot

bolts which allow the tensioner rail to pivot about its axis.

The spring tensioner for both chains is provided from a single unit which contains two spring operated, hydraulically

damped plungers that operate on the tensioning rails at the slack side of each of the timing chains. Pressurised oil for

the adjuster is supplied through the back of the unit from an oil supply port in the front of the cylinder block. The lateral

movement in the tensioner arm causes the timing chain to tension and consequently, compensation for chain flutter

and timing chain wear is automatically controlled.

The timing chains are oil splash lubricated via the oil pump and chain tensioner. Oil spray is directed to the chain from

several oil supply ports in the front of the cylinder block and cylinder head.

An additional chain from the crankshaft sprocket connects to the oil pump sprocket for oil pump operation.

Cylinder Head Components

The cylinder head components are described below:

Cylinder Head

Although the Td6 is of an in-line configuration its cylinders are arranged into 2 sets of three. The forward set consists

of cylinders 1 to 3 and the rear bank consists of cylinders 4 to 6.

The cylinder head is of aluminium gravity die casting construction. The cylinder head is bolted to the cylinder block by

means of M12 cylinder head bolts arranged beneath each camshaft.

NOTE: The cylinder head bolts are not accessible with the camshafts fitted.

ENGINE – TD6

12-1-10 DESCRIPTION AND OPERATION

Inlet Port Configuration

1 Exhaust ports

2 Exhaust valves

3 Fuel injector

4 Inlet swirl port

5 Inlet valves

6 Inlet tangential port

7 Glow plug

The aluminium cylinder head houses the chain driven overhead camshafts, valve gear, fuel injectors and glow plugs.

The Td6 engine has a 4–valve arrangement, similar to the Td4. There are two exhaust ports, combined in the cylinder

head, a tangential inlet and a swirl inlet port. The common fuel injector rail is centrally mounted with the glow plug

fitted to the inlet side.

Coolant flow enters the head from the exhaust side and exits, between No 3 and No 4 cylinder, the inlet side to the

heater matrix and radiator. The Engine Coolant Temperature (ECT) sensor is screwed into an aperture at the rear LH

side of the cylinder head.

+ ENGINE MANAGEMENT SYSTEM – Td6, DESCRIPTION AND OPERATION, Description.

+ COOLING SYSTEM – Td6, DESCRIPTION AND OPERATION, Description.

Cylinder Head Cover

The plastic moulded cylinder head cover is used to seal off the oil chamber in the cylinder head. It shields oil spray

from the camshaft and the chain drive gear, and acts as a housing for the valve gear.

An oil separator for the crankcase ventilation system is mounted at the top of the cover. This provides preliminary oil

separation by cyclone, and fine separation using an internal yarn wrap. The separator unit also contains a pressure

control valve.

The camshaft cover includes an integrated air filter housing which is de-coupled from the cylinder head to absorb and

minimise the transmission of engine noise. The camshaft cover also provides a mounting for the mass air-flow (MAF)

sensor.

Cylinder Head Gasket

The multi-layed steel cylinder head gasket has cylinder specific water flow cross-sections for uniform coolant flow.

There are three thicknesses of gasket available, selected according to the determined piston clearance. The thickness

of the gasket is identified by the number of identification holes, one hole being the thinnest and three holes being the

thickest.

1

6

M12 7769

3

7

2

5

4

ENGINE – TD6

DESCRIPTION AND OPERATION 12-1-11

Vacuum Pump

The vacuum pump is located on a support bracket at the front RH side of the cylinder head and is driven from the

exhaust camshaft.

Camshafts

There are two camshafts, exhaust (right) and intake (left). Each camshaft is maintained in position by seven bearing

caps. Each bearing cap is fixed to the cylinder head by two bolts. The camshafts are made using the clear chill casting

process and are hollow cast. The cam lobes have a negative cam radius. The camshafts are driven from the

crankshaft using a simplex chain and sprocket arrangement.

Each camshaft has twelve machined lobes for operating the inlet and exhaust valves through lash adjusters and roller-

type finger levers.

Inlet and Exhaust Valves

Valve Gear Layout

The inlet and exhaust valves are identical and have ground, solid one-piece head and stems made from Nimonic alloy

material.

The valve springs are made from spring steel and are of the parallel single-coil type. The bottom end of each spring

rests on the flange of a spring retainer which has an integral valve stem seal. The top end of the spring is held in place

by a spring retainer which is held in position at the top end of the valve stem by split taper collets. The taper collets

have grooves on the internal bore that locate to grooves ground into the upper stems of the valves.

Valve seats and valve guides are an interference fit in the cylinder head.

M12 7768

ENGINE – TD6

12-1-12 DESCRIPTION AND OPERATION

Hydraulic Lash Adjusters and Roller Finger Rockers

The valves are operated through roller-type finger rockers and hydraulic lash adjusters, actuated by the camshaft

lobes. When the camshaft lobe presses down on the top of a finger rocker, roller mechanism, the respective valve is

forced down, opening the affected inlet or exhaust port. The use of this type of actuation method helps reduce friction

in the valve timing mechanism.

The body of the hydraulic lash adjusters contains a plunger and two chambers for oil feed and pressurised oil. The

pressurised oil is supplied to the lash adjusters via the main oil galleries in the cylinder head and through a hole in the

side of the lash adjuster body. The oil passes into a feed chamber in the lash adjuster and then through to a separate

pressure chamber via a one way ball valve.

Oil flow from the pressure chamber is determined by the amount of clearance between the lash adjuster outer body

and the centre plunger. Oil escapes up the side of the plunger every time the lash adjuster is operated, the downward

pressure on the plunger forcing a corresponding amount of oil in the lash adjuster body to be displaced. When the

downward pressure from the camshaft and finger rocker is removed (i.e. after the trailing flank of the camshaft lobe

has passed), oil pressure forces the lash adjuster's plunger up again. This pressure is not sufficient to effect the valve

operation, but eliminates the clearance between the finger rocker and top of the valve stem.

Electronic Fuel Injectors

There are six electronic fuel injectors (one for each cylinder), each located in the centre of a cylinder's four valves.

The electronic fuel injectors are supplied with fuel from the fuel rail and deliver finely atomised fuel directly into the

fuel chambers.

+ ENGINE MANAGEMENT SYSTEM – Td6, DESCRIPTION AND OPERATION, Description.

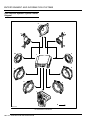

Ancillary Components and Belt Drives

The ancillary components, which comprise the torsional vibration damper, alternator, A/C compressor, steering pump

and water pump, are driven by the engine crankshaft via the ancillary drive belts.

The belts, which are maintenance free poly-V type belts, are automatically pre-loaded by the tensioning rollers and

are routed over deflection pulleys in order to maintain sufficient adhesion about the drive wheels. This ensures slip-

free drive of the ancillary components.

ENGINE – TD6

DESCRIPTION AND OPERATION 12-1-13

Belt Drive

1 Water pump

2 Tensioning pulley

3 Power steering pump

4 Alternator pulley

5 Idler pulley

6 Torsional vibration damper

7 A/C compressor

Torsional Vibration Damper

The torsional vibration damper with decoupled belt pulley suppresses longitudinal vibration and reduces noise. It is

mounted to the forward end of the crankshaft with 4 central bolts torque loaded to 45 Nm.

Tensioning Pulley

The tensioning pulley or idler pulley is a spring-loaded element.

Lubrication

The lubrication system is a wet sump, pressure fed type. It lubricates the engine sliding surfaces, dissipates heat,

absorbs fuel combustion residue and seals off the gap between the cylinder and piston.

M12 7763A

2

6

2

1

3

4

7

5

ENGINE – TD6

12-1-14 DESCRIPTION AND OPERATION

Lubrication Circuit

1 Pressure supply to upper chain lubrication

2 Camshaft bearing

3 Runout stop – Hydraulic Valve Adjuster gallery

4 Hydraulic valve lash adjuster gallery (HVA)

5 Piston spray nozzle — hook-type nozzle

6 Cylinder block main oil gallery feed for

crankshaft bearings

7 Oil filter with oil cooler

8 Oil gallery after oil filter — main oil gallery

9 Oil intake pipe

10 Unfiltered oil duct

11 Oil pump

12 Pressure supply for upper chain lubrication

13 Pressure supply to Turbo-charger

14 Riser to cylinder head

15 Pressure supply to vacuum pump

Operation

Oil from the sump is drawn up through a fabricated metal pick-up pipe which contains a mesh to filter out any relatively

large pieces of material which could cause damage to the oil pump. The head of the pick-up is centrally immersed in

the sump oil which is delivered to the inlet side of the eccentric rotary pump.

The oil pump is driven from the crankshaft by a chain and sprocket system. Pressurised oil from the pump is passed

through a port in the bottom of the cylinder block and is directed up to the oil inlet port of the oil cooler and filter housing

via a port in the RH side of the cylinder block. The oil pump contains an oil pressure relief valve which opens to allow

oil to be recirculated back around the pump if the oil pressure increases to a high enough level.

9

11

8

7

4

5

3

2

1

15

14

M12 7764

13

10

12

6

ENGINE – TD6

DESCRIPTION AND OPERATION 12-1-15

The inlet port of the oil cooler and filter housing has an integral non-return valve which allows flow into the filter, but

prevents unfiltered oil draining back out of the filter housing when oil pressure is reduced.

The oil passes through the oil filter element and out to the oil cooler. The percentage of oil flow passed through to the

oil cooler is dependent on a thermostatic by-pass valve which is integrated into the oil filter housing. An increase in

oil temperature causes the by-pass valve to open and allow a greater percentage of oil flow to be directed through the

oil cooler. The remainder of the oil flow from the outlet side of the filter element is directed to the outlet port of the oil

filter housing where it combines with the oil flow being returned from the oil cooler before being passed back into the

cylinder block.

An oil pressure switch is included in the outlet port of the oil filter housing to sense the oil pressure level before the oil

flow enters the main oil gallery in the engine block. A warning lamp in the instrument pack is switched on if the oil

pressure is detected to be too low.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

Oil entering the cylinder block main gallery passes through drillings to the crankshaft main bearings and cross drillings

in the crankshaft direct oil to the big-end bearings. An additional four drillings in the cylinder block supply oil at reduced

pressure to the lubrication jets for piston and cylinder cooling and gudgeon pin lubrication.

A cross channel from the LH main oil gallery crosses to the RH side of the cylinder block where there is an outlet port

which provides a pressurised oil supply to the turbocharger bearings via a banjo connection and external piping.

Riser channels at the front RH side and rear LH side of the cylinder block are used to channel oil to mating ports in

the cylinder head and provide a source for cylinder head lubrication and operating pressure for the lash adjusters.

Oil is fed through oil galleries at the LH and RH side of the engine and six cross channels from each gallery directs

oil to the camshaft bearings. Lubrication oil fed to the lash adjusters passes up through the lash adjuster's body to the

finger rockers for lubrication of the surfaces between the finger rockers and the camshaft lobes.

Tapered plugs seal the cylinder head oil galleries at the rear of the cylinder head, and an additional tapered plug is

included inside the cylinder head at the front of the RH gallery.

An additional riser channel from the cylinder block LH main oil gallery is used to supply lubrication to the timing chain

system through several outlet ports at the front of the cylinder block and cylinder head.

ENGINE – TD6

12-1-16 DESCRIPTION AND OPERATION

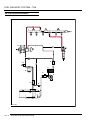

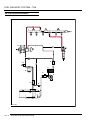

Engine Mounts

System Layout

1 Right hydraulic damper

2 Right engine mounting

3 Left engine mounting

4 Left hydraulic damper

5 Vacuum supply pipe

6 Engine mount damping control actuator

Two hydraulically dampened engine mounts are fitted between the engine support brackets and engine sub-frame to

reduce the level of transmitted engine vibration and noise.

The damping characteristics of the mounts are regulated by controlling the rate of hydraulic fluid transfer between two

internal chambers.

The system consists of two hydraulic mounts, with variable damping regulated by a vacuum, a control actuator,

electric and vacuum lines. The vacuum, controlled by the electrical control actuator, is supplied via a distributor in the

vacuum line between the vacuum pump and brake booster. The system is controlled by the EDC System.

ENGINE – TD6

DESCRIPTION AND OPERATION 12-1-17

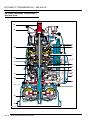

Hydraulic Engine Mount

1 Vacuum connection

2 Bellows

3 Nozzle

4 Annular channel

5 Diaphragm

6 Upper hydraulic chamber

7 Orifice

8 Upper nozzle plate

9 Nozzle

10 Lower nozzle plate

11 Lower hydraulic chamber

12 Support cup

13 Spring

14 Channel

M12 7766

10

3

4

5

6

8

7

9

14

12

13

11

1

2

ENGINE – TD6

12-1-18 DESCRIPTION AND OPERATION

Operation

By applying a vacuum, the Engine Control Module (ECM) controls the engine damping mounting in two stages:

“Hard” Engine Mount

In the basic setting no vacuum is applied to the hydraulic mount. The spring (13) acts on the support cup (12) to close

the U-bellows against the upper nozzle plate (8). Hydraulic fluid flows from the upper hydraulic chamber (6) via the

nozzle (9), the annular channel (4) and via nozzle (3) into the lower hydraulic chamber (11).

The annular channel extends over approximately 300 degrees. Due to the length of the annular channel and the small

nozzle orifice hydraulic oil flows between the upper and lower hydraulic chamber only in the case of vibrations up to

the natural frequency of the engine (approximately. 10 Hz), thus producing a vibration absorber effect.

At higher frequencies, the equalisation between the hydraulic chambers is inhibited by the length of the annular

channel and the small nozzle orifices. In practical terms, equalisation between the upper and lower hydraulic chamber

does not take place.

Diaphragms (5) are fitted in the holes (7) of the nozzle plates in order to achieve good acoustic characteristics at high

frequencies with small amplitude.

"Soft" Engine Mount

At idling speed and in the speed range close to idling, the spring (13) is pulled down by applying vacuum at vacuum

connection (1). The channel (14) in the centre of the upper nozzle plate now acts as a bypass between the upper and

lower hydraulic chamber. This allows the hydraulic fluid to flow unrestricted between the upper and lower chambers.

The increase in the fluid flow rate softens the damping action of the hydraulic mount, reducing the dynamic rigidity of

the engine mount.

EDC Parameters

The ECM controls the engine mounts based on the following parameters:

Switching Value

Engine Speed 900 RPM

Vehicle speed 60 km/h (36 MPH)

ENGINE – TD6

DESCRIPTION AND OPERATION 12-1-19

Vacuum Supply

Distributor

The vacuum necessary for activating the engine mounts is obtained via a distributor located in the vacuum line

between the vacuum pump and brake booster.

For this purpose, the vacuum line of the damping-controlled hydraulic mount is connected to the long outlet of the

distributor.

The vacuum varies within the pressure range from 0.5 to 0.9 bar. It is switched by means of a damping control

actuator.

ENGINE – TD6

12-1-20 DESCRIPTION AND OPERATION

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-1

ENGINE - V8DESCRIPTION AND OPERATION

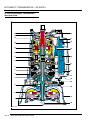

V8 – External View

M12 7816

ENGINE - V8

12-2-2 DESCRIPTION AND OPERATION

Description

General

The V8 petrol engine is a 4.4 litre, eight cylinder water cooled engine having two banks of four cylinders, arranged at

90 degrees to each other, with four valves per cylinder. The engine emissions comply with ECD3 (European

Commission Directive) and NAS LEV 2 legislative requirements. The engine comprises five main castings - two

cylinder heads, cylinder block, timing cover and the oil sump, all of which are manufactured from aluminium alloy.

Plastic rocker covers are fitted to the cylinder heads and, between the cylinder heads, is a plastic manifold intake

assembly. A plastic moulded acoustic cover is fitted over the upper engine to reduce engine generated noise.

The engine is supported, between cast mounting brackets and the front subframe, on two self-contained hydraulically

damped mounts.

Technical Features

The technical features include:

l Four valves per cylinder

l Single plenum chamber

l Variable Camshaft Control (VCC) system

l Double roller timing chain

l Hydraulic Valve Adjusters (HVA)

l Water Cooled Oil Cooler.

Engine Data

The technical data is detailed below

The cylinders are numbered as follows:

NOTE: Cylinders 4 and 8 are at the rear of the engine

Cylinder Block Components

The cylinder block components are described below:

Engine type 90° V

Cylinders 8

Displacement 4398 ccm

Stroke/bore 82.7/92.0 mm

Maximum Power 210 kW (285 PS; 282 bhp) @ 5400

rev/min

Maximum Torque 440 Nm (324 lbf.ft) @ 3600 rev/min

Compression ratio 10: 1

Firing order 1–5–4–8–6–3–7–2

Left bank 5 — 8

Right bank 1 — 4

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-3

Crankcase

The crankcase is made from Alusil for markets where the fuel contains a high sulphur content. The cylinder barrels

have a nickel dispersion coating (Nikasil), and are finished by polishing only.

An adaptor plate for the feed and return flexible pipes to the oil filter assembly is fitted to the left side of the crankcase.

A water drain plug is located at the lower LH rear corner to drain coolant from the crankcase.

Crankcase Ventilation

The crankcase ventilation system is pressure regulated by a valve mounted at the rear of the inlet manifold. Vacuum

supply ports are incorporated on the valve for the power brake booster and the fuel pressure regulator

The pressure regulating vent valve varies the vacuum applied to the crankcase depending on engine load. The valve

is balanced between spring pressure and the amount of manifold vacuum. At idle when the vacuum is high, the valve

closes down and only allows a small amount of blow-by vapours to pass into the manifold. At part to full load

conditions, the spring opens the valve and additional blow-by gasses flow into the manifold. An additional tube leads

the blow-by gasses through the manifold and up to the mixing plate.

The crankcase ventilation system is completely sealed. Hose clamps are used at all connections to ensure that the

system does not contain any leaks.

The crankcase ventilation system uses a cyclone separator to purge the blow-by gasses of any oil vapours. The oil

vapours condense in the separator and drain back into the sump.

ENGINE - V8

12-2-4 DESCRIPTION AND OPERATION

Crankcase Ventilation System

1 Oil separator

2 Breather hose, oil separator to vent valve

3 Breather hose, LH camshaft cover to oil

separator

4 Inlet manifold cover and vent valve

5 Inlet manifold

6 Oil drain pipe assembly

7 Inlet manifold vacuum pipe

8 Mixing plate

9 Vent valve spring

10 Vent valve diaphragm

11 Atmospheric vent

12 Blow-by gasses

M12 7839A

1

2

3

4

5

6

10

7

9

12

11

7

8

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-5

Crankshaft

The crankshaft is manufactured from forged steel with five main bearings and the thrust bearing on number five

bearing. Six counterweights fitted. These are positioned in harmony with the ignition firing order to ensure smooth

running.

The crank pins are offset by 90° and hollow bored to reduce weight.

There are four sizes of crankshaft available, standard and three undersizes.

Colour coding identifies the size of the journal.

The main bearing caps have a unique four bolt fixing for additional strength, and threaded protective bushes which

are torqued before the collar screws are installed.

NOTE: For information on colour coding and journal sizes, refer to the General Data section of the workshop manual.

At the front of the crankshaft, incorporated in the auxiliary belt pulley is a torsional vibration damper. Fitted behind the

damper, to the crankshaft, is the drive sprocket for the camshaft and oil pump.

Torsional Vibration Damper

The torsional vibration damper with decoupled belt pulley suppresses longitudinal vibration and reduces noise. It is

mounted at front of the crankshaft with 4 bolts torque loaded to 45 Nm.

ENGINE - V8

12-2-6 DESCRIPTION AND OPERATION

Bearing Shells

The upper bearing shells have oil grooves and a drilling to provide oil, via drillings in the crankshaft to the crankshaft

main bearings and the connecting rod journals

Flywheel

1 Flywheel

2 Torque converter attachment holes

3 Reluctor ring

4 Starter motor ring gear

The single piece steel flywheel is bolted to the rear of the crankshaft with nine bolts. The torque converter is bolted to

the rear of the flywheel with four bolts.

Attached to the flywheel is the reluctor ring for the crankshaft position sensor and the starter motor ring gear.

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-7

Connecting Rods

The connecting rods are sintered type, one piece forged rods which feature a fracture-split at the big-end between the

connecting rod and the bearing cap. The mating surface of the rod and bearing cap form a rough surface (interference

fit) that eliminates the need for centering sleeves. Each matched rod and bearing cap pair is stamped with a pairing

code.

All of the rods are of one weight class and conform to the double bearing classification, red or blue. One red and one

blue bearing shell are fitted to each connecting rod. The red shell is fitted to the bearing cap.

Pistons

The pistons are of a short skirt design and “iron coated” for use with the Alusil block. Each piston has a flat crown

surface with a front facing arrow for installation direction. The relevant cylinder bank number is engraved into the

piston crown.

Each piston is fitted with two compression rings and an oil control ring.

There are no thermal control strips in the pistons. The pistons are cooled with specific spray jets, mounted in the

crankcase.

M12 7806

ENGINE - V8

12-2-8 DESCRIPTION AND OPERATION

Piston Lubrication Jets

Hook-type nozzles are connected directly into an oil gallery in the crankcase and secured by two screws.

The jets provide lubrication to the cylinder walls, and to the piston underskirt for cooling the pistons and lubricating

the gudgeon pins and small-end bearings.

M12 7843

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-9

Timing Case Covers

Separate timing case covers are bolted to the two cylinder heads and the crankcase.

The upper timing case covers have ports for the VCC solenoid valves and Camshaft Position (CMP) sensors. The

lower cover has an integral mounting for the alternator which acts as a water jacket. A drain plug and sealing ring is

fitted to the bottom of the mounting.

Rubber pre-formed gaskets form seals between the cylinder heads and crankcase and respective timing case covers.

ENGINE - V8

12-2-10 DESCRIPTION AND OPERATION

Sump

The two-piece aluminium die-cast sump, with an integral tunnel for the differential drive shaft, is sealed to the lower

crankcase extension using a rubber metal-backed gasket. The sump is fixed to the lower crankcase extension using

25 bolts. An oil deflector plate is attached to the crankcase reinforcing shell above the sump. The sump incorporates

a drain plug and a dip-stick guide tube.

Oil Pump

The oil pump housing and cover is manufactured from cast aluminium. The gear type oil pump is driven via the

crankshaft.

The oil pump is located in the sump and is attached to Nos 1 and 2 main bearing caps. The rotor-type pump produces

a regulated pressure of approximately 4.5 bar.

A metal suction pipe obtains oil from the sump.

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-11

Oil Filter Assembly

The oil filter assembly, with a replaceable element, is mounted remote to the engine. It is attached to a mounting

bracket fitted to the left of the radiator and the filter is mounted on two rubber mounts to reduce vibration.

Two re-inforced flexible hoses, feed and return, are fitted between the filter assembly and the crankcase mounted

adaptor plate. The hose connections are of the push fit type and sealed with an “O” ring seal. The filter hose

connections are secured by a locking plate bolted to the filter body. The sump hose connections are secured to the

crankcase adaptor with a securing bracket. This bracket is attached with a stud and nut.

A by-pass valve is located internally in the lower end of the filter body. This allows the oil to by-pass the filter if the

filter element becomes blocked

A second valve is screwed into the filter body. It is connected to a rigid pipe on the sump by a flexible hose secured

by two hose clips. The rigid pipe has a banjo fitting on the sump connection. When the filter is removed, the valve

opens allowing oil in the housing to drain to the sump.

The oil pressure switch screws into the base of the filter body.

ENGINE - V8

12-2-12 DESCRIPTION AND OPERATION

Cylinder Head Components

The cylinder head components are described in the following paragraphs.

Cylinder Head Cover

The cylinder head cover is manufactured from magnesium alloy and is secured to the cylinder head with 11 threaded

spacers with rubber seals. The right hand cover incorporates an oil filler cap.

The cylinder head cover also provides mounting for the coils. The coils are protected by a plastic cover, sealed with

a rubber gasket. The cover is retained with two bolts which are covered with protective caps.

NOTE: Damage to the magnesium cover may cause corrosion.

Cylinder Heads

The cross flow cylinder heads are made of die-cast aluminium and feature:

l Centrally located spark plugs

l Four valves per cylinder

l Two camshafts

l Bucket tappets with hydraulic valve clearance adjusters.

The combustion chambers are machined into the heads, thus ensuring more uniform “matched” combustion

chambers and compression pressures.

Bolted to the front end of the cylinder head are the oil distribution flanges. The flanges provide a mounting for the VCC

solenoids and the advance-retard ports from the solenoids to the intake camshafts.

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-13

The cylinder heads for each bank are different lengths due to the offset of the cylinder rows (cylinder bank 1–4 is

shorter).

NOTE: The cylinder head gasket part numbers are different for the two cylinder banks.

The cylinder head is machineable to a limit of 0.3 mm. A repair cylinder head gasket is available and is identified by

a small hole beside the 4th and 8th cylinder apertures.

Camshafts

Two solid cast iron camshafts are used for each cylinder head. The cams run in five machined bearing surfaces with

numbered caps for identification.

The camshafts are also marked for identification and incorporate hexagonal machined blocks for timing the cams

during installation.

For installation and servicing, the camshafts are held in position with locking pins. These pins are inserted into the

front camshaft bearing caps on both cylinder heads.

Valves

The intake and exhaust valves are arranged in a “V” pattern. The valves use single, conical, coil bound shaped valve

springs and Hydraulic Valve Adjustment (HVA) tappets and each comprises the following components:

l Valve x 1 (inlet or exhaust)

l Valve stem seal x 1

l Valve spring x 1

l Valve spring seat x 1

l Valve spring cap x 1

l Valve collets x 2

l Tappet x 1.

Hydraulic Valve Adjustment Tappets

Bucket type hydraulic tappets are used for adjusting the valve clearance. The buckets are self-breathing with a carbon

nitride finished cam contact surface.

Primary drive

Primary drive is provided by a single roller chain from the crankshaft to the two rubber coated cam gears. The train is

guided by a centrally positioned V-shaped aluminium deflector rail, a straight rail on cylinder bank 5 to 8 and a curved

tensioner rail on cylinder bank 1 to 4.

Timing chain adjustment is carried out with a hydraulic tensioner mounted on the upper case for cylinders 1 to 4

Secondary Drive

Secondary drive is from the intake camshaft to the exhaust camshaft by a single roller chain. Chain tension is

maintained by a hydraulic, spring assisted tensioner that incorporates an oil spray jet.

The oil supply for the chain tensioner also supplies the VCC hydraulic units through a pressure control valve.

ENGINE - V8

12-2-14 DESCRIPTION AND OPERATION

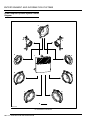

Ancillary Components and Belt Drive

The ancillary components, the torsional vibration damper, alternator, A/C compressor, steering pump and water

pump, are driven by the engine crankshaft by the aid of the ancillary drive belts. The A/C compressor is driven by a

separate belt.

The belts, which are maintenance free poly-vee type belts, are automatically pre-loaded by two tensioning spring pots

and are routed over deflection pulleys in order to maintain sufficient adhesion about the ancillary pulleys. This ensures

slip-free drive of the ancillary components.

Belt Drive

1 Coolant pump

2 Idler pulley

3 Alternator

4 Power assisted steering pump

5 Tensioner pulley

6 Crankshaft pulley

7 Tensioner pulley

8 A/C compressor

Air Intake System

The inlet manifold is a light weight, one piece plastic moulding. Fuel is supplied by a single fuel rail and regulated by

a single pressure regulator mounted on the end of the rail. The manifold is acoustically decoupled from the cylinder

heads to reduce noise and vibrations.

The throttle plate has two wedges screwed directly to it, these provide a curved zone for smoother throttle response

during idle, off-idle transition.

The combined output of the mixing plate ensures that the gasses and vapours are evenly distributed among all the

cylinders, which can improve idle quality.

M12 7815A

8

7

6

5

4

3

2

1

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-15

Lubrication

The lubrication system is a wet sump, pressure fed type. It lubricates the engine sliding surfaces, dissipates heat and

absorbs fuel combustion residue.

Operation

Oil from the sump is drawn up through a fabricated metal pick-up pipe which contains a mesh to filter out any relatively

large particles of material which could cause damage to the oil pump. The head of the pick-up is centrally immersed

in the sump oil which is delivered to the rotor pump.

Variable Camshaft Control (VCC)

The V8 engine uses a VCC (Variable Camshaft Control) system for valve timing on the intake camshaft. While the

engine is running the inlet camshafts are continuously adjusted to their optimum position.

Both camshafts are simultaneously adjusted to a maximum of 20° of the crankshaft rotational axis. This equates to a

maximum span of 40° crankshaft rotation.

+ ENGINE MANAGEMENT SYSTEM – V8, DESCRIPTION AND OPERATION, VCC System.

Cylinder Bank Components

Each cylinder bank contains the following:

l Cylinder head with oil ports for the VCC system

l Control solenoid valve

l VCC Transmission and sprockets

l Oil distribution flanges

l Oil check valve

l Camshaft position impulse wheels

l Camshaft position sensors.

Control Solenoid Valve

The control solenoid valve is fitted with an integral non-return valve and has four ports:

1 Input supply port — engine oil pressure

2 Output retard port — to rear of piston/helical gear (retarded camshaft position)

3 Output advance port — to rear of piston/helical gear (advanced camshaft position)

4 Vent — released oil pressure.

The non-return valve is fitted to the rear of the solenoid valve in the cylinder head oil gallery. The non-return valve

maintains an oil supply in the VCC transmission and oil circuits after the engine is switched off. This prevents piston

movement when the engine is restarted.

+ ENGINE MANAGEMENT SYSTEM – V8, DESCRIPTION AND OPERATION, VCC System.

VCC Transmission and Sprockets

The primary and secondary timing chain sprockets are integrated with the self-contained VCC transmission.

The controlled adjustment of the camshaft occurs inside the “transmission”. Controlled oil pressure moves the piston

axially.

The helical gear cut of the piston acts on the helical gears on the inside surface of the transmission and rotates the

camshaft to the specific advanced or retarded angle position.

Three electrical pin contacts are located on the front surface to verify the default maximum retard position using an

ohmmeter. This is required during assembly and adjustment.

Oil Distribution Flanges

The oil distribution flanges are bolted to the front surface of each cylinder head. They provide a mounting location for

the VCC solenoids as well as the advance-retard oil ports from the solenoids to the intake camshafts.