Firman WH03041 Manual de usuario

- Categoría

- Generadores de poder

- Tipo

- Manual de usuario

P/N:330745470 Rev:00

OWNER’S MANUAL

Read all safety precautions and instructions carefully

before operating equipment.

Ensure engine is stopped and level before performing

any maintenance or service.

IMPORTANT:

Record product information to reference when ordering parts or

obtaining warranty coverage.

Serial Number:

DUAL FUEL INVERTER GENERATOR

MODEL NUMBER

WH03041

Rev Level:00

DO NOT RETURN TO

STORE!

CALL US FIRST!

CUSTOMER HOTLINE

1-844-347-6261

FOR QUESTIONS OR SERVICE

INFORMATION

Purchase Date:

Table of Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety Precautions . . . . . . . . . . . . . . . . . . . . .2

Unpacking The Generator. . . . . . . . . . . . . . .7

Parts Included. . . . . . . . . . . . . . . . . . . . . .7

Controls and Features. . . . . . . . . . . . . . . . . 8

Generator. . . . . . . . . . . . .. . . . . . . . . . . . . .8

Control Panel. . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . 10

. . . . . . . . . . . 10

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . 11

Add Engine Oil . . . . . . .. . . . . . . . . . . . . . . .12

Low Oil Shutdown . . . . . . . . . . . . . . . . . . . .12

Add Fuel . . . . . . .. . . . . . . . . . . . . . . . . . . . .13

. . . . . . . . . . .16

Grounding. . . . .. . . . . . . . . . . . . . . .. . . . . .17

System.. . . . . . . . . . . . . . . . . . . . . . .. . . . . .17

Operation . . . . . . . . . . . . . . . . . . . . . . . . .. . . . 18

Generator Location . . . . . . . . . . . . . . . . . . 18

Surge Protection . . . . . . . . . . . . .. . . . . . . .18

Starting the Generator(Recoil Start-Gas).19

Starting the Generator(Recoil Start-LPG).19

.21

.22

Connecting Electrical Loads . . . . . . . .. . . 23

Economy Control Switch. . . . . . . .. . . . . . 24

12V DC Outlet (Battery Charger).. . . . . . 24

Stopping the Engine . . . . . . . . . . . . . . . . . 25

Low Oil Shutdown . . . . . . . . . . . . . . . . . . 25

Do Not Overload Generator . . . . . . . . . . . 25

Parallel Operation. . . . . . . . . . . . . . . . . . . 26

Introduction

Battery Cable Connection

Regulator Cover Installation

Operation at High Altitude

Starting the Generator (Electric Start-Gas)

Starting the Generator (Electric Start-LPG)

Connecting to a Building’s Electrical

English Customer Service: 1-844-FIRMAN1

Maintenance And Storage. . . . . . . . . . . . . . 27

Maintenance Schedule . . . . . . . . . . . . . 27

Engine Maintenance .. . . . . . . . . . . .. . . . 28

Change Engine Oil . . .. . . . . . . . . . . . . . 28

Air Filter Maintenance. . . . . . . . . . . . . .28

Spark Plug Maintenance. . . . . . . . . . . . 29

. . . 30

Generator Maintenance . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . 30

Charging The Generator Battery. . . . . . 31

Service and Storage . . . . . . . . . . . . . . . .. 32

Trouble Shooting . . . . . . . . . . . . . . . . . . . . .33

Parts Diagram and Parts List . . . . . . . . . . 34

Generator Parts Diagram . . . . . . . . . . . . 34

Engine Parts Diagram . . . . . . . . . .. . . . . 35

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . 36

Service Information . . . . . . . . . . . . . .. . . . . 38

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Inspect Muffler and Spark Arrester

Battery Replacement

Thank you for purchasing a FIRMAN generator.

This manual covers operation and maintenance of the FIRMAN generators. All information in this

publication is based on the latest production information available at the time of approval for printing.

The manufacturer reserves the right to change, alter or other wise improve the generator and this

documentation at any time without prior change.

Page 01

This manual contains safety information to make you aware of the hazards and risks associated

with generator products and how to avoid them. This generator is designed and intended only

for supplying electrical power for operating compatible electrical lighting, appliances, tools and

motor loads, and is not intended for any other purpose. It is important that you read and

understand these instructions thoroughly before attempting to start or operate this equipment.

Save these original instructions for future reference.

Important Safety Information

The manufacturer cannot possibly anticipate every possible circumstance that might involve a

hazard. The warnings in this manual and the tags and decals affixed to the unit are therefore not

all-inclusive. If you use a procedure, work method or operating technique that the manufacturer

does not specifically recommend you must satisfy yourself that it is safe for you and others. You

must also make sure that the procedure work method or operating technique that you choose

does not render the generator unsafe.

SAFETY INFORMATION

DANGER WARNING CAUTION

DANGER indicates a

potentially hazardous

situation which, if not

avoided. WILL result in

death or serious injury.

WARNING indicates a

potentially hazardous

situation which, if not

avoided, could result in

death or serious injury.

CAUTION indicates a

potentially hazardous

situation which, if not

avoided, may result in minor

or moderate personal injury,

or property damage.

Toxic Fumes

Fire Hazard

Hot Surface.

Do Not Touch the Surface.

Kickback

Risk of Electric Shock

Explosion Hazard

Rotating Parts Entanglement

Hazard

Operator’s Manual

INTRODUCTION

English Customer Service: 1-844-FIRMAN1

SAFETY PRECAUTIONS

Page 02

WARNING

POISONOUS GAS HAZARD.

•

•

•

•

•

English Customer Service: 1-844-FIRMAN1

Page 03

CORRECT USAGE

Example location to reduce risk of carbon monoxide poisoning

•ONLY use outside and downwind, far away from windows, doors and vents.

•Direct exhaust away from occupied spaces.

INCORRECT USAGE

Do not operate in any of the following locations:

Near any door, window or vent

Garage

Basement

Crawl Space

Living Area

Attic

Entry Way

Porch

Mudroom

English Customer Service: 1-844-FIRMAN1

Page 04

WHEN OPERATING EQUIPMENT

•

DO NOT tip engine or equipment at angle

which causes fuel or oil to spill.

DO NOT stop engine by moving choke

control to “Start” position.

•

•

WHEN TRANSPORTING, MOVING

OR REPAIRING EQUIPMENT

Transport/move/repair with fuel tank

EMPTY or with fuel shut OFF.valve

•

•DO NOT tip engine or equipment at angle

which causes fuel or oil to spill.

Disconnect spark plug wire.

•

WHEN STORING FUEL OR EQUIPMENT

WITH FUEL IN TANK

•

WARNING

•

•

WARNING

Generator voltage could cause

electrical shock or burn resulting

in death or serious injury.

•

WARNING

•

•NEVER start or stop engine with electrical

devices plugged in and turned on.

WARNING

Gasoline, gasoline vapors and liquid petroleum

gas(LPG) are extremely flammable and explosive

which could cause burns, fire, or explosion resulting

in death or serious injury and/or property damage.

WHEN ADDING OR DRAINING GASOLINE

Turn generator engine OFF and let it cool at

least 2 minutes before removing fuel cap.

Loosen cap slowly to relieve pressure in tank.

Fill or drain fuel tank outdoors.

•

•DO NOT overfill tank. Allow space for fuel

expansion.

If fuel spills, wait until it evaporates before

starting engine.

•

Keep fuel away from sparks, open flames,

pilot lights, heat, and other ignition sources.

Check fuel lines, tank, cap, and fittings

frequently for cracks or leaks. Replace if

necessary.

DO NOT light a cigarette or smoke.

•

•

•

•

WHEN STARTING EQUIPMENT

Ensure spark plug, muffler, fuel cap, and air

cleaner are in place.

•

DO NOT crank engine with spark plug

removed.

•Use approved transfer equipment, suitable

for the intended use, to prevent backfeed by

isolating generator from electric utility

workers.

English Customer Service: 1-844-FIRMAN1

Make certain that a LPG cylinder is not attached

to generator and is securely stowed away.

•

Do not store gasoline or LPG cylinder near

furnaces, water heaters, or any other appliances

that produce heat or have automatic ignitions.

•

Page 05

WARNING

Unintentional sparking

could cause fire or

electric shock resulting

in death or serious

injury.

WHEN ADJUSTING OR MAKING REPAIRS TO

YOUR GENERATOR

Disconnect the spark plug wire from the

spark plug and place the wire where it cannot

contact spark plug.

•

WHEN TESTING FOR ENGINE SPARK

Use approved spark plug tester.

•DO NOT check for spark with spark plug

removed.

•

WARNING

NEVER operate generator without protective

housing or covers.

DO NOT wear loose clothing, jewelry or

anything that could be caught in the starter

or other rotating parts.

Tie up long hair and remove jewelry.

•

•

•

•

•

DO NOT exceed the generator’s wattage

amperage capacity.

Start generator and let engine stabilize

before connecting electrical loads.

NOTE:

•

•

•

•

CAUTION

Exceeding generators wattage/amperage capacity

could damage generator and/or electrical devices

connected to it.

Connect electrical loads in OFF position,

then turn ON for operation.

Turn electrical loads OFF and disconnect

from generator before stopping generator.

•

•

•

DO NOT use generator with electrical cords

which are worn, frayed, bare or otherwise

damaged.

DO NOT operate generator in the rain or

wet weather.

DO NOT handle generator or electrical

cords while standing in water, while

barefoot, or while hands or feet are wet.

DO NOT allow unqualified persons or

children to operate or service generator.

•

WARNING

Exhaust heat/gases could ignite combustibles,

structures or damage fuel tank causing a fire,

resulting in death or serious injury and/or

property damage.

Contact with muffler area could cause burns

resulting in serious injury.

DO NOT touch hot parts and AVOID hot

exhaust gases.

Allow equipment to cool before touching.

It is a violation of California Public Resource

Code, Section 4442, to use or operate the

engine on any forest-covered, brush-covered,

or grass-covered land unless the exhaust

system is equipped with a spark arrester, as

defined in Section 4442, maintained in

effective working order. Other states or

federal jurisdictions may have similar laws.

Contact the original equipment manufacturer,

retailer, or dealer to obtain a spark arrester

designed for the exhaust system installed on

this engine.

Replacement parts must be the same and

installed in the same position as the original

parts.

•

•

•

•

When using generator for backup power,

notify utility company.

Use a ground fault circuit interrupter (GFCI)

in any damp or highly conductive area,

such as metal decking or steel work.

DO NOT touch bare wires or receptacles.

•

•

•

English Customer Service: 1-844-FIRMAN1

Page 06

•

•

•

•

•

Use generator only for intended uses.

If you have questions about intended use,

ask dealer or contact local service center.

Operate generator only on level surfaces.

DO NOT expose generator to excessive

moisture, dust, dirt, or corrosive vapors.

DO NOT insert any objects through cooling

slots.

If connected devices overheat, turn them off

and disconnect them from generator.

Shut off generator if:

-Electrical output is lost.

-Equipment sparks, smokes, or emits flames.

-Unit vibrates excessively.

•

•

WARNING

Medical and Life Support Uses.

In case of emergency, call 911 immediately.

NEVER use this product to power life support

devices or life support appliances.

NEVER use this product to power medical

devices or medical appliances.

Inform your electricity provider immediately

if you or anyone in your household depends

on electrical equipment to live.

Inform your electrical provider immediately

if a loss of power would cause you or anyone

in your household to experience a medical

emergency.

•

•

•

•

•

NOTE:

Improper treatment of generator could damage

it and shorten its life.

English Customer Service: 1-844-FIRMAN1

Fuel Safety

DANGER

GASOLINE AND GASOLINE VAPORS ARE HIGHLY

FLAMMABLE AND EXPLOSIVE.

Fire or explosion can cause severe burns or death.

Unintentional startup can result in entanglement,

traumatic amputation or laceration.

Gasoline expands or contracts with ambient

temperatures. Never fill the gasoline tank to

full capacity, as gasoline needs room to expand

if temperatures rise.

Gasoline can cause a fire or explosion if ignited.

Gasoline is a liquid fuel but it’s vapors can ignite.

•

•

•Gasoline is a skin irritant and needs to be cleaned

up immediately if spilled on skin or clothes.

•Gasoline has a distinctive odor, this will help

detect potential leaks quickly.

•In any gasoline fire, flames should not be

extinguished unless by doing so the fuel supply

valve can be turned OFF. This is because if a fire is

extinguished and a supply of fuel is not turned OFF,

then an explosion hazard could be created.

•

Liquid Petroleum Gas (LPG/Propane):

This generator is dual fuel and capable of running

with both gasoline and Liquid Petroleum Gas

(LPG/Propane).

•

If you smell gas: close off the gas supply. Make

sure there is no leak before using the generator.

•

•

•

•

•

•

Gasoline:

Liquid Petroleum Gas (LPG) is highly flammable

and explosive. Fire or explosion can cause severe

burns or death.

Do not use or store LPG cylinder in a building,

garage or enclosed area.

Do not check for leaks with a lighted match or

flame.

The LPG cylinder valve should be fully closed

when the generator is not in use or is running

with gasoline.

DANGER

WARNING

Device used for handling LPG must be installed

and used in strict conformance with NFPA 58

(Liquefied Petroleum Gas Code) and NFPA 54

(National Fuel Gas) and all other codes, regulations

and manufacturer recommendations.

Never use a gas container, LPG connector

hose, LPG cylinder or any other fuel item that

is damaged or appears damaged.

The LPG cylinder valve should be fully closed

when the generator is not in use or is running

with gasoline.

•

•The regulator/hose assembly and cylinder

valve must be inspected before each use for

leaks or sign of damages.

1. Engine Oil(Bottle) . . . . . . . . . . . . . . . . . . . . . . . 1

2. Oil Funnel . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . 1

3. Wrench for Spark Plug . . . . . . . . . . . . . . . . . . . .1

4. Screwdriver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. Battery Charge Cable . . . . . . . . . . . . . . . . . . . . .1

6. Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

7. Quick Reference Guide . . . . . . . . . . . . . . . . . . . 1

8. Battery Float Charger(12V DC) . . . . . . . . . . . 1

LPG Regulator/ Hose Assembly. . . . . . . .. . . . 19.

2

1

Quick

Reference

Guide

3

Manual

6

4

57

8

Page 07

English Customer Service: 1-844-FIRMAN1

UNPACKING THE GENERATOR

•

•

Parts Included

Your gasoline powered generator ships with

the following parts:

If you smell gas: close off the gas supply. Spray

a soapy water solution to check all connections

for leaks before attempting to use generator.

Contact a qualified technician to inspect and

repair the LPG system if a leak found before

using the generator.

•

CAUTION

LPG under pressure is highly flammable and

can cause a fire or explosion if ignited.

LPG is heavier than air and can accumulate in

confined spaces and low places in the event

of a leak.

LPG has a distinctive odor to help detect

potential leaks.

Do not allow children to tamper or play with

the LPG cylinder.

In the event of an LPG fire, flames should not

be extinguished unless by doing so the fuel

supply valve can be turned off. If the fire is

extinguished and a supply of fuel is not turned

off, an explosion hazard greater than the fire

hazard could be created.

Keep a fire extinguisher near the generator all

the time.

Always keep the LPG cylinder in an upright

position.

Do not subject LPG cylinder to excessive heat.

Contact with liquid contents of the cylinder

will cause freeze burns to the skin.

An LPG cylinder not connected for use shall

not be stored in the vicinity of the generator.

When transporting and storing, turn off the

cylinder valve and fuel selector switch, and

disconnect the cylinder.

•

•

•

•

•

•

•

•

•

•

•

9

Page 08

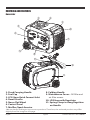

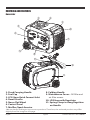

CONTROLS AND FEATURES

Generator

*We are always working to improve our products. Therefore, the enclosed product may differ

slightly from the image on this page.

1- Fixed

2- Fuel Cap

3- LPG Hose Quick Connect Inlet

4- Recoil Starter

5- Never Flat Wheel

6- Control Panel

7- Muffler/Spark Arrester

Carrying Handle

English Customer Service: 1-844-FIRMAN1

⑨

②

③

①

④

⑤

⑥

⑦

①

⑧

8- Folding Handle

9- Maintenance Cover – Oil filler and

air filter access.

10- LPG Hose with Regulator

11- Spring Clamp to Hang Regulator

on Handle

⑪

⑩

Page 09

Control Panel

1

2

3

4

6

Total power drawn from all receptacles must not exceed the name plate rating.

NOTE:

English Customer Service: 1-844-FIRMAN1

5

7

Oil Warning Indicator Light – Check oil level when

this light turns “ON”. Engine will not run when

indicator is lit.

8

Overload Indicator Light – This light turns “ON”

when the generator is overloaded and will cut

power to the receptacles.

9

Output Ready Indicator Light – Remains “ON”

during normal operating conditions. Shuts “OFF”

when generator is overloaded.

10

Economy Control Switch

The Economy Control switch can be activated in order to

minimize fuel consumption and noise while operating the

unit during times of reduced electrical output, allowing

the engine speed to idle during periods of non-use. The

engine speed returns to normal when an electrical load is

connected. When the economy switch is off, the engine

runs at normal speed continuously.

When the oil falls below the minimum level, the oil

warning indicator light comes on and the engine

stops automatically. The engine will not start until

the proper amount of oil is in the crank case.

The green AC Power Indicator Light comes on

when the engine starts and generates power.

If the engine overload indicator light comes on, the

generator’s wattage / amperage capacity has been

exceeded by connected electrical devices or by a

power surge. When this occurs, the green AC Power

Indicator Light(Item 7) will go off. The engine will

continue to run, but the red Engine Overload Indicator

Light will stay on and power will no longer be supplied

to connected electronic devices.

3-1 Data-Minder(Multi-Meter) – Push the SELECT

button to show the Voltage, Hertz and running hours.

120V, 20A Duplex – (NEMA 5-20R) 20 Amp of current

may be drawn from this 120 Volt receptacle.

120V, 30A RV (NEMA TT-30R) Maximum full load

30 Amp current may be drawn from this 120 Volt receptacle.

–

Engine Switch – To start engine, press the switch

in the “RUN”(l) position.

DC 5V 2.1A USB Outlet

Circuit Breakers – The receptacles are protected by

an AC circuit protector. If the generator is overloaded

or an external short circuit occurs, the circuit protector

will trip. If this occurs, disconnect all electrical loads and

try to determine the cause of the problem before

attempting to use the generator again. If overloading

causes the circuit protector to trip, reduce the load.

Note: Continuous tripping of the circuit protector

may cause damage to generator or equipment. The

circuit protector may be reset by pushing the button

of the protector.

6

9

7

8

10 11

12

13

15

14

1

2

34

5

16

17

18

19

20

21

Battery Power Restore Switch

11

22

Page 10

English Customer Service: 1-844-FIRMAN1

12

14

15

Parallel Operation Outlets - These outlets are used

for connecting two FIRMAN inverter generators for

parallel operation. A FIRMAN parallel kit(optional

equipment) is required for parallel operation.

12V DC outlet – 8.3 Amp of DC current may be drawn

from this receptacle.

Use this outlet to charge 12V automotive type

batteries ONLY. See 12V DC outlet (Battery

Charger) section.

16

DC Circuit Breaker - The circuit protector may be reset

by pushing the button of the protector.

Ground Terminal – Consult an electrician for local

grounding regulations.

17

18

Outlet Cover - Protect the receptacles from dust

and debris.

LPG Regulator Solenoid Port

Recoil Stater

Choke Button

12V DC Battery Charger Port - Plug the 120 Volt

AC charger into this port to charge the generator

battery.

13

19

Battery Cable Connection

1.Unscrew the maintenance cover by provided

screwdriver.

2. Cut wire tie that is binding the black battery

cables A and B.

3. Insert the male connector of cable A into

female connector of cable B.

4. Reattach the maintenance cover.

Follow below instruction to connect battery to

the generator:

LPG Hose Quick Connect Inlet

20

21

22

Fuel Selector Switch Used to select and turn on

gas or LPG fuel source.

-

Regulator Cover Installation

A

B

C

D

Follow below instruction to install the LPG

regulator cover:

1, Place the LPG regulator cover A over the LPG

regulator B.

2, Use M5X14(QTY:3) C and M5X35(QTY:1) D

screws to tighten the LPG regulator cover.

Page 11

SPECIFICATIONS

AN IMPORTANT MESSAGE ABOUT TEMPERATURE:

Your Firman Power Equipment product is designed and rated for continuous operation at

ambient temperatures up to 40°C (104°F). When your product is needed, your product may be

operated at temperatures ranging from -15°C (5°F) to 50°C (122°F) for short periods. If the

product is exposed to temperatures outside this range during storage, it should be brought back

within this range before operation. In any event, the product must always be operated outdoors,

in a well-ventilated area and away from doors, windows and other vents.

When operated above 77°F(25°C) there may be a decrease in power.

Maximum wattage and current are subject to and limited by such factors as fuel BTU content

ambient temperature, altitude, engine condition and etc. Maximum power decreases about

3.5% for each 1,000 feet above sea level; and will also decrease about 1% for each 10°F(6°C)

above 60°F(16°C) ambient temperature.

•

•

Model

Rated AC Voltage

Phase

Power Factor

Voltage regulator

Alternator Type

Running Watts

Starting Watts

Engine

Engine Type

Displacement

Low Oil Shutdown

Ignition System

Starting System

Fuel

Capacity Fuel Tank

Lubricating Oil Capacity

Carburetor Type

Air Cleaner

P.T.O. shaft rotation

120V

WH03041

3300(GASOLINE)/3000(LPG)

Digital

Single Phase

1

Single Cylinder, 4-Stroke OHV Air Cooled

171 cc

Breakless Ignition Type, Flywheel Magneto

Unleaded Automotive Gasoline/LPG

1.8 Gallon

20.3 oz(0.6L)

Counter Clockwise (Facing P.T.O.)

Float

Polyurethane Type

YES

FIRMAN

Rated Fequency 60Hz

Oil Type

See “Add Engine Oil” Section

English Customer Service: 1-844-FIRMAN1

Magneto Inductor

Recoil

Total Harmonic Distortion(THD) <3%

AC Grounding System

Floating Neutral

3000(GASOLINE)/2700(LPG)

Add Engine Oil

Page 12

DO NOT attempt to crank or start the engine

before it has been properly filled with the

recommended type and amount of oil. Damage

to the generator as a result of failure to follow

these instructions will void your warranty.

1.Place generator on a flat and level surface.

2.Loosen the cover screw and remove the

maintenance cover.

NOTE:

The recommended oil type is 10W-30 automotive

oil. However outdoor temperatures will determine

the space proper oil viscosity for the engine. Use the

chart to select the best for the outdoor temperature

range expected.

The engine is equipped with a low oil shut-off and

will stop when the oil level in the crankcase falls

below the threshold level.

NOTE:

We consider the first 5 hours of run time to be

the break-in period for the unit. During the break

in period stay at or below 50% of the running

watt rating and vary the load occasionally to allow

stator windings to heat and cool. Adjusting the

load will also cause engine speed to vary and help

seat piston rings.

CAUTION

The unit is equipped with a low oil shutdown.If

the oil level becomes lower than required,the

sensor will activate a warning device or stop the

engine.

If generator shuts off and the oil level is within

specifications, check to see if generator is sitting

at an angle that forces oil to shift. Place on an

even surface to correct this. If engine fails to

start, the oil level may not be sufficient to

deactivate low oil level switch. Make sure the

sump is completely full of oil.

5.Replace oil fill cap/dipstick and fully tighten.

6.Reinstall maintenance cover and tighten screws.

4.Using oil funnel, slowly pour contents of

provided oil bottle into oil fill opening to the

"H" mark on dipstick. Be careful do not

overfill. Overfilling with oil could cause the

engine to not start or hard starting.

Low oil shutdown

Degrees Celsiusº(Outside)

Full Synthetic 5W-30

Degrees Fahrenheitº(Outside)

5W-30 10W-40

10W-30

CAUTION

English Customer Service: 1-844-FIRMAN1

3.Remove oil fill cap/dipstick .

7.Oil Level should be checked prior to each use or

at least 8 hours or operation. Keep oil level maintained.

DRAIN PLUG

HIGH

H

H

L

Add Fuel

Page 13

Fuel must meet these requirements:

•Clean, fresh, unleaded gasoline.

Use regular UNLEADED gasoline with the

generator engine with a minimum 87 octane

/ 87 AKI (91 RON).

For high altitude use, see "Operation at High

Altitude".

Do not use gasoline with more than 10%

alcohol such as E85 or ethanol.

•

•

Failure to follow Operator's Manual for fuel

recommendations voids warranty.

Avoid generator damage.

DO NOT use unapproved gasoline such as E85.

DO NOT mix oil in gasoline.

DO NOT modify engine to run on alternate fuels.

•

•

•

WARNING

Fuel and its vapors are extremely flammable

and explosive which could cause burns, fire or

explosion resulting in death, serious injury

and/or property damage.

WHEN ADDING FUEL

Fill fuel tank outdoors.

DO NOT overfill tank. Allow space for fuel

expansion. If the tank is overfilled, fuel

can overflow onto a hot engine and cause fire

or explosion. Wipe up any spilled fuel

immediately.

If fuel spills, wait until it evaporates before

starting engine.

Keep fuel away from sparks, open flames,

pilot lights, heat, and other ignition sources.

Check fuel lines, tank, cap and fittings

frequently for cracks or leaks. Replace if

necessary.

DO NOT light a cigarette or smoke when

filling the fuel tank.

•

•

•

•

1.Clean area around fuel fill cap, remove cap.

2.Slowly add unleaded fuel to fuel tank. Be

careful not to fill above the red fuel level

indicator . This allows adequate space for

fuel expansion.

3.Install fuel cap and let any spilled fuel

evaporate before starting engine or wipe up

any spilled gasoline.

English Customer Service: 1-844-FIRMAN1

CAUTION

Slowly add unleaded gasoline to fuel tank.

Do not overfill tank.

•

•

•Do not fill above the red fuel level indicator.

This will allow expansion in hot weather and

prevent overflow.

Fuel Level Indicator

IMPORTANT: It is important to prevent gum

deposits from forming in fuel system parts such

as the carburetor, fuel hose or tank during

storage. Alcohol-blended fuels (called gasohol,

ethanol or methanol) can attract moisture, which

leads to separation and formation of acids during

storage. Acidic gas can damage the fuel system

of an engine while in storage. To avoid engine

problems, the fuel system should be emptied

before storage of 30 days or longer. See the

" Long Term Storage" section. Never use engine

or carburetor cleaner products in the fuel tank

as permanent damage may occur.

1.Gasoline

2-Connecting Liquid Petroleum Gas

(LPG/Propane) Cylinder

•

•

Liquid Petroleum Gas (LPG) is highly flammable

and explosive. Fire or explosion can cause severe

burns or death.

Do not use or store LPG cylinder in a building,

garage or enclosed area.

DANGER

•Do not place the LPG cylinder in the path of

muffler outlet.

Page 14

English Customer Service: 1-844-FIRMAN1

•Never use a gas container, LPG connector

hose, LPG cylinder or any other fuel item that

is damaged or appears damaged.

The LPG cylinder valve should be fully closed

when the generator is not in use or is running

with gasoline.

•

•The regulator/hose assembly and cylinder

valve must be inspected before each use for

leaks or sign of damages.

Use only 20 or 30 lb capacity cylinders with

Type 1, right hand Acme threads with this

generator. Verify the re-qualification date

on the tank has not expired. Do not use rusted

or damaged cylinders.

All new cylinders must be purged of air and

moisture prior to filling. Used cylinders that

have not been plugged or kept closed must

also be purged. The purging process should

be done by your propane gas supplier.

Do not connect or disconnect the LPG cylinder

in enclosed area.

Do not install or replace the LPG cylinder near

open flames, pilot lights, or sparking electrical

equipment such as power tools, welders and

grinders.

If you smell gas: close off the gas supply. Spray

a soapy water solution to check all connections

for leaks before attempting to use generator.

Contact a qualified technician to inspect and

repair the LPG system if a leak found before

using the generator.

•

•WARNING

Device used for handling LPG must be installed

and used in strict conformance with NFPA 58

(Liquefied Petroleum Gas Code) and NFPA 54

(National Fuel Gas) and all other codes, regulations

and manufacturer recommendations.

If you smell gas: close off the gas supply. Make

sure there is no leak before using the generator.

•

•

•

Do not check for leaks with a lighted match or

flame.

The LPG cylinder valve should be fully closed

when the generator is not in use or is running

with gasoline.

D(Regulator Assembly)

A(LPG Regulator/Hose Assembly)

B(LPG Regulator

solenoid plug)

C(Quick Connect

Fitting)

Page 15

English Customer Service: 1-844-FIRMAN1

Remove the cap/plug and attach the quick

connect fitting C to the quick connect in let

located on the control panel.

Attach the LPG regulator solenoid plug B to

the LPG regulator solenoid port located on

the control panel.

Remove the safety cap/plug from the cylinder

valve and attach the LPG regulator assembly

D to the LPG cylinder.

Tighten the nut by hand clock wise to a positive

stop.

Do not use a wrench to tighten .

Use of wrench may damage quick closing coupling

nut and result in a hazardous condition.

NOTE:

Do not use tape or any type sealant to seal the

LPG hose connections.

Always position the cylinder so the connection

between the valve and the regulator won’t cause

bends or kinks in the hose.

Spray a soapy water solution (one part liquid

detergent and one part water) to check all

connections for leaks before attempting to

use generator. Slowly open the cylinder valve.

A leak exists if bubbles appear or grow larger

in size or number. This must be corrected before

using the generator. Contact your local

Authorized Service Facility for assistance. Do

not attempt to make repairs yourself.

You must use the supplied regulator/hose

assembly for safe operation.

Do not check for leaks with a lighted match or flame.

Do not light or smoke cigarettes.

Check the fuel system periodically for leaks

or signs of damages.

Page 16

English Customer Service: 1-844-FIRMAN1

Operation at High Altitude

At altitudes over 5,000 feet(1524 meters), a

minimum 85 octane / 85 AKI (89 RON) gasoline

is acceptable.

The density of air at high altitude is lower

than at sea level. Engine power is reduced

as the air mass and air-fuel ratio decrease.

Engine power and generator output will be

reduced approximately 3.5% for every 1000 feet

of elevation above sea level. This is a

natural trend and cannot be changed by

adjusting the engine. At high altitudes

increased exhaust emissions can also result

due to the increased enrichment of the air

fuel ratio.

Other high altitude issues can include hard

starting, increased fuel consumption and

spark plug fouling. To a l l e v i a t e hi gh

al titud e issues o ther tha n the n atura l

power loss, FIRMAN can provide a high

altitude carburetor main jet. The alternative

The part number and recommended minimum

altitude for the application of the high

altitude carburetor main jet is listed in the

table below.

main jet and installation instructions can be

obtained by contacting Customer Support.

Installation instructions are also available in the

Technical Bulletin area of the FIRMAN internet site.

OPEN

WARNING

3-Permanent Connection to a large

Propane supply tank:

In the instance that you would need to connect

your generator to a large propane Supply tank,

larger than 20 or 30 lb DOT cylinder, it is

recommended to contact your Gas Equipment

Company. Various equipment for use with LPG,

is required for proper conformance to all NFPA

regulations. Your Gas Equipment Company can

help you select and install the proper regulator,

fittings and connections to meet all the Codes

and manufacturer regulations. Each installation

may be different and will required proper equipment.

Contact your Gas Equipment Company to assure

that you are meeting all NFPA 58 (Liquefied

Petroleum Gas Code) and NFPA 54 (National Fuel

Gas) Codes.

When transporting and storing, turn off the

cylinder valve and fuel selector switch, and

disconnect the cylinder.

Contact with liquid contents of the cylinder

will cause freeze burns to the skin.

•

An LPG cylinder not connected for use shall

not be stored in the vicinity of the generator.

•

•

•Always keep the LPG cylinder in an upright

position.

Do not subject LPG cylinder to excessive heat.

•

In the event of an LPG fire, flames should not

be extinguished unless by doing so the fuel

supply valve can be turned off. If the fire is

extinguished and a supply of fuel is not turned

off, an explosion hazard greater than the fire

•

hazard could be created.

•Keep a fire extinguisher near the generator

all the time.

Altitude main jet 1

Altitude main jet 2

171cc

330717004

330717005

Altitude

3000-6000Feet

6000-8000Feet

LPG under pressure is highly flammable and

can cause a fire or explosion if ignited.

CAUTION

•

LPG is heavier than air and can accumulate in confined

spaces and low places in the event of a leak.

LPG has a distinctive odor to help detect

potential leaks.

•

•

Do not allow children to tamper or play with

the LPG cylinder.

•

Page 17

Use approved transfer equipment to prevent

backfeed by isolating generator from electric

utility workers.

When using generator for backup power, notify

utility company.

Use a ground fault circuit interrupter (GFCI) in

any damp or highly conductive area, such as

metal decking or steel work.

DO NOT touch bare wires or receptacles.

DO NOT use generator with electrical cords

which are worn,frayed, bare or otherwise

damaged.

DO NOT operate generator in the rain or wet

weather.

DO NOT handle generator or electrical cords

while standing in water, while barefoot, or

while hands or feet are wet.

DO NOT allow unqualified persons or children

to operate or service generator.

Connecting to a Building's Electrical System

Connections for standby power to a building's

electrical system must be made by a qualified

electrician. The connection must isolate the

generator power from utility power or other

alternative power sources and must comply

with all applicable laws and electrical codes.

WARNING

Generator voltage could cause

electrical shock or burn resulting

in death or serious injury.

•

•

•

•

•

•

•

•

English Customer Service: 1-844-FIRMAN1

Grounding

The National Electric Code requires your generator

must be properly connected to an appropriate

ground to help prevent electric shock.

Failure to properly ground the

generator can result in electric

shock.

WARNING

A ground terminal connected to the frame of

the generator has been provided on the control

panel. For remote grounding, connect of a

length of heavy gauge (12 AWG minimum)

copper wire between the generator ground

terminal and a copper rod driven into the

THERE IS A PERMANENT CONDUCTOR BETWEEN

THE GENERATOR (STATOR WINDING) AND THE

FRAME.

ground. We strongly recommend that you

consult with a qualified electrician to ensure

compliance with local electrical codes.

Page 18

Surge Protection

Voltage fluctuation may impair the proper

functioning of sensitive electronic equipment.

Electronic devices, including computers and

many programmable appliances use components

that are designed to operate within a narrow

voltage range and may be affected by momentary

voltage fluctuations. While there is no way to

prevent voltage fluctuations, you can take steps

to protect sensitive electronic equipment.

Install UL1449, CSA-listed, plug-in surge

suppressors on the outlets feeding your

sensitive equipment. Surge suppressors come

in single- or multi-outlet styles. They’re

de s i g n e d to pr o t e ct a g a i n s t vir t u a ll y

all short-duration voltage fluctuations.

Operate this product ONLY outside far away

from windows, doors and vents to reduce

the risk of carbon monoxide gas from

accumulating and potentially being drawn

towards occupied spaces.

•

•Install battery-operated carbon monoxide

alarms or plug-in carbon monoxide alarms

with battery back-up according to the

manufacturer’s instructions. Smoke alarms

cannot detect carbon monoxide gas.

•

DO NOT run this product inside homes,

garages, basements, crawlspaces, sheds, or

other partially-enclosed spaces even if using

fans or opening doors and windows for

ventilation. Carbon monoxide can quickly

build up in these spaces and can linger for

hours, even after this product has shut off.

•ALWAYS place this product downwind and

point the engine exhaust away from

occupied spaces. If you start to feel sick,

dizzy, or weak while using this product, shut

it off and get to fresh air RIGHT AWAY. See a

doctor. You may have carbon monoxide

poisoning.

CAUTION

English Customer Service: 1-844-FIRMAN1

OPERATION

Generator Location

Make sure you review each warning in order to

prevent fire hazard.

Keep area clear of inflammables or other

hazardous materials.

Select a site that is dry, well ventilated and

protected from the weather.

Keep exhaust pipe clear of foreign objects.

Keep generator away from open flame.

Keep generator on a stable and level surface.

WARNING

WARNING

POISONOUS GAS HAZARD.

Engine exhaust contains carbon

monoxide, a poisonous gas that

could kill you in minutes. You

CANNOT smell it, see it, or taste

it. Even if you do not smell exhaust

fumes, you could still be exposed

to carbon monoxide gas.

Avoid other generator hazards.

READ MANUAL BEFORE USE.

Do not block generator air vents with paper or

other material.

CAUTION

Tilting can cause fuel spillage.

Page 19

English Customer Service: 1-844-FIRMAN1

Starting the Generator (Recoil Start-Gasoline)

1. Before starting the generator, check for loose

or missing parts and for any damage which

may have occurred during shipment.

2. Check oil level and fuel.

9. Pull the starter cord slowly until resistance is

felt and then pull rapidly.

11. Allow generator to run at no load for few

minutes upon each initial start-up to permit

engine and generator to stablize.

10. Push the choke button to the “RUN” position.

6. Flip the engine switch to the “RUN"(l) position.

5. Disconnect all electrical loads from the

generator. Never start or stop the generator

with electrical devices plugged in or turned

on.

3. Make sure the LPG cylinder knob is fully closed.

8. Pull the choke lever out to the "CHOKE" position.

7. Push the battery power restore switch for about

3 seconds and then release.

Starting the Generator (Recoil Start-LPG)

NOTE: hen the fuel

selector switch is in “GAS” position(4:30 o’clock).

To close this valve, turn the slector switch to the

“ LPG” position (1:30 o’clock).

The gasoline valve is OPEN, w

NOTE: The generator will NOT start with LPG without

battery power or an appropriate connection.

1. Before starting the generator, check for loose

or missing parts and for any damage which

may have occurred during shipment.

4. Turn the fuel selector switch to “GAS” position(4:30 o’clock).

Page 20

English Customer Service: 1-844-FIRMAN1

11. Push the choke button to the “RUN” position.

7. Flip the engine switch to the “RUN"(l) position.

6. Disconnect all electrical loads from the generator.

Never start or stop the generator with electrical

devices plugged in or turned on.

5. Turn the fuel selector switch to “LPG” position(1:30 o’clock).

9. Pull the choke lever out to the "CHOKE" position.

8. Push the battery power restore switch for about

3 seconds and then release.

4. Fully open the LPG cylinder knob.

Use your fingers, slide the outer barrel back on

the LPG quick connect hose fitting. While the outer

barrel is in the back position, insert the LPG hose

(included) into the inlet and release the outer barrel.

The barrel will automatically return and lock the

hose in the inlet.

10. PULL TO-PRIME:-

Pull the starter cord 1-2 times. Pull slowly until

resistance if felt and then pull rapidly.

12. PULL TO RUN:- -

Pull the starter cord slowly until resistance if felt

and pull rapidly to run the unit.

If the engine fails to start in 1-2 pulls with choke in the

“RUN” position, then move choke lever to “START”

position and repeat the “PULL-TO-PRIME” step.

3. Connect the regulator(A) to both LPG cylinder

and generator. Connect the power cord(B) to the

LPG regulator port. See “Connecting liquid Petroleum

Gas(LPG/Propane) ” section on page 13, 14,15.Cylinder

2. Check oil level.

Page 21

English Customer Service: 1-844-FIRMAN1

13. Allow generator to run at no load for few

minutes upon each initial start-up to permit

engine and generator to stablize.

Starter cord kickback(rapid

retraction) will pull hand and arm

toward engine faster than you can

let go which could cause broken

WARNING

When starting engine, pull cord slowly until

resistance is felt and then pull rapidly to avoid

kickback.

bones, fractures, bruises, or sprains resulting in

serious injury.

If engine starts after 3 pulls but fails to run, or if

unit shuts down during operation, make sure

unit is on a level surface and check for proper

oil level in crankcase. This unit may be equipped

with a low oil protection device. If so, oil must

be at proper level for engine to start.

Keep choke lever in “CHOKE” position for only 1

pull of the recoil starter. After first pull, move

choke lever to the “RUN” position for up to the

next 3 pulls of the recoil starter. Too much

choke leads to sparkplug fouling/engine

flooding due to the lack of incoming air. This

will cause the engine not to start.

3.Plug in and turn on the desired 120 Volt AC,

single phase, 60Hz electrical loads. It is

better to attach the item with largest load first.

Connecting Electrical Loads

1.Let engine stabilize and warm up for a few

minutes after starting.

2.Ensure circuit breaker on control panel is in

on position.

This unit has been pretested and adjusted to

handle its full capacity. Before starting the

generator, disconnect all load. Apply load only

after generator is running. Voltage is regulated

via the engine speed adjusted at the factory for

correct output. Readjusting will void warranty.

CAUTION

When applying a load, do not exceed the maximum

wattage rating of the generator when using one or

more receptacles. Also, do not exceed the amperage

rating of any one receptacle.

Do not apply heavy electrical load during break-in

period (the first five hours of operations).

Connecting a generator to your electric utility

company’s power lines or to another power

source may be against the law. In addition this

action, if done incorrectly, could damage your

generator and appliances and could cause

serious injury or even death to you or a utility

worker who may be working on nearby power

lines. If you plan to run a portable electric

generator during an outage, please notify your

electric utility company immediately and

remember to plug your appliances directly into

the generator. Do not plug the generator into

any electric outlet in your home. Doing so could

create a connection to the utility company

power lines. You are responsible for ensuring

that your generator’s electricity does not feed

back into the electric utility power lines.

If the generator will be connected to a building

Page 24

English Customer Service: 1-844-FIRMAN1

electrical system, consult your local utility

company or a qualified electrician. Connections

must isolate generator power from utility

power and must comply with all applicable laws

and codes.

Economy Control Switch

The Economy Control switch can be activated in

order to minimize fuel consumption and noise

while operating the unit during times of reduced

electrical output, allowing the engine speed to

idle during periods of non-use. The engine speed

returns to normal when an electrical load is

connected. When the economy switch is off, the

engine runs at normal speed continuously.

WARNING

For periods of high electrical load or momentary

fluctuations, the Economy Control Switch should

be turned OFF.

12V DC Outlet (Battery Charger)

The 12V DC outlet is ONLY to be used with the

supplied 12V battery charging cable. The DC

output is unregulated and will damage other

12V DC products.

The amount of current flowing will depend on the

charging voltage and battery's state of charge. As

the battery becomes more fully charged, the output

current to the battery decreases and nearly becomes

constant. Taper chargers are intended to be used

with the provision that they will be disconnected

from the battery after a maximum time on charge.

Normally a period of 30 to 120 minutes is sufficient

to recharge a weak battery. The charge level of the

battery should be checked periodically.

1. Before connecting the battery charging cable

to a battery that is installed in a vehicle, disconnect

the vehicle battery ground cable from the

negative (–) battery terminal.

Do not continue to charge a battery that becomes

hot or is fully charged.

2. Plug the battery charging cable into the DC

receptacle of the generator.

3. Connect the red (+) battery charger lead to the

red (+) battery terminal.

4. Connect the black (–) battery charger lead to

the black (–) battery terminal.

5. Start the generator.

NOTE:

When the battery circuit is in use the AC capacity

is reduced by 100 watts. Make sure the combined

load is within the rated limits.

WARNING

Do not continue to charge a battery that becomes

hot or is fully charged.

CAUTION

Storage batteries give off EXPLOSIVE hydrogen

gas while charging. Do not allow smoking, open

flames, sparks, or spark producing equipment

in the area while charging.

WARNING

Do not start the vehicle while the battery charging

Cable is connected and the generator is running.

It will not give the battery a boost of power. The

Vehicle or the generator may be damaged. Charge

only vented wet lead acid batteries. Other types

of batteries may burst, causing personal injury

or damage.

Battery electrolyte fluid is comprised of sulfuric

acid that can be very dangerous and cause severe

burns. Do not allow this fluid to contact eyes, skin,

clothing, etc. If contact or spillage does occur,

flush the area with water immediately.

WARNING

For use with 12V direct current outlet, always

keep the ECO mode deactivated (OFF Position).

•

•You can use the 12V direct current outlet and

the 230V current at the same time, but keep

the ECO mode deactivated (OFF Position) at

all times.

Page 25

English Customer Service: 1-844-FIRMAN1

A DC circuit protector has been provided to

protect the circuit from overloads. If an overload

occurs, the circuit protector will trip. The circuit

protector may be reset by pushing the button of

the protector.

DC CIRCUIT PROTECTOR

Charging a large capacity battery or a totally

discharged battery may cause the DC breaker to

turn off. In these cases, a separate battery charger

unit connected to an AC power source is

recommended instead of the DC receptacle on

the generator.

Stopping the Engine

1. Turn off and remove entire electrical loads.

Never start or stop the generator with

electrical devices plugged in or turned on.

Let the generator run at no-load for two minutes to stabilize

internal temperatures of the engine and generator.

2. Flip the engine switch to“OFF”(O) position.

Low Oil Shutdown

If the engine oil drops below a preset level, an

oil switch will stop the engine. Check oil level

with dipstick.

If oil level is between the LOW and HIGH mark on

dipstick:

1.Add oil to bring level to HIGH mark.

2.Restart engine and if the engine stops again

a low oil condition may still exist. DO NOT try

to restart the engine.

3.Contact an Authorized FIRMAN Service Dealer.

4.DO NOT operate engine until oil level is

corrected.

Do Not Overload Generator

Overloading a generator in excess of its rated

wattage capacity can result in damage to the

generator and to connected electrical devices.

To prolong the life of your generator and

attached devices, follow these steps to add

electrical load:

1.DO NOT try to restart the engine.

2.Contact an Authorized FIRMAN Service Dealer.

3.DO NOT operate engine until oil level is corrected.

If oil level is below the LOW mark on dipstick:

DO NOT stop engine by moving choke control

to “START” position.

Important: Always ensure that the

is in the “OFF” position when the engine

is not in use.

fuel selector

switch

explosion resulting in death, serious injury

and/or property damage.

If the engine will not be used for a period of two

weeks or longer, please see the Storage section

for proper engine and fuel storage.

3. Turn the fuel selector switch to “ ” position

(1:30 o’clock). The gasoline valve is close on this

position.

LPG

4. Fully close the LPG cylinder knob.

If a cover is used, do not install until unit has cooled.

WARNING

Fuel and its vapors are extremely flammable and

explosive which could cause burns, fire or

NOTE: Disconnect the LPG cylinder from the

generator during transportation.

Page 26

English Customer Service: 1-844-FIRMAN1

Observing frost on LPG and regulators

is common during operation and normally is not

an indication of a problem. As LPG vaporizes and

travels from the tank to the generator engine it

expands. The amount of frost that forms can be

affected by the size of the cylinder, the amount

of fuel being used, the humidity of the air and other

operating conditions. In unusual situations this

frost may eventually restrict the flow of LPG gas

cylinders

NOTE:

to the generator resulting in deteriorating

performance. For example, if the tank temperature

is reduced to a very low level then the rate at which

the LPG vaporizes is also reduced and may not

provide sufficient fuel flow to the engine. This is

not an indication of a problem with the generator

but only a problem with the flow of gas from the

LPG cylinder. If generator performance seems

to be deteriorating at the same time that ice

formation is observed on tank valve, hose or

regulator then some actions may be taken to

eliminate this symptom. In these rare situations

it can be helpful to reduce or eliminate the cold

fuel system effects by doing one of the following:

The LPG cylinder can be temporarily warmed

by pouring warm water over the top of the

cylinder.

Exchanging fuel tanks to allow the first tank

to warm up, repeating as necessary

•

Placing the LPG cylinder at the end of the

generator near the handle, where engine fan

air flows out from the generator. This air is

slightly heated by flowing over the engine.

•

•

DO NOT PLACE THE LPG CYLINDER IN THE PATH

OF MUFFLER OUTLET.

DANGER

Muffler

Parallel Operation

1. Disconnect any electronic devices, and then

stop the engine.

2. Reduce the total wattage of connected

electronic devices until it is within the generator’s

rated output.

3. Inspect the Air Inlet and Control Panel for any

blockage. Remove blockage if found.

4. Restart Engine.

How to Correct

CAUTION:

DO NOT disconnect parallel cables while generator

is running.

Any two FIRMAN inverter generator with parallel

port including two FIRMAN inverter model WH03041

can be paralleled to increase the total available

electrical power to 5500 Watts (on gasoline

application). A FIRMAN Parallel kit (not included) is

Overload Operation

The overload indicator light will turn on and cut

power to the receptacles after 30 seconds when

the load exceeds 3080W(approximately).

The overload indicator light will turn on and cut

power to the receptacles after 2 seconds when

the load exceeds 3150W(approximately).

For Kit availability, call customer Service at 1-844-

347-6261 or visit: www.firmanpowerequipment.com.

required for parallel operation.

1. Start the generator with no electrical load

attached.

2. Allow the engine to run for several minutes

to stabilize.

3. Plug in and turn on the first item. It is best to

attach the item with the largest load first.

4. Allow the engine to stabilize.

5. Plug in and turn on the next item.

6. Allow the engine to stabilize.

7. Repeat steps 5-6 for each additional item.

MAINTENANCE AND STORAGE

Page 27

General Recommendations

Regular maintenance will improve the performance and extend the life of the generator. See any

authorized dealer for service.

The generator's warranty does not cover items that have been subjected to operator abuse or

negligence. To receive full value from the warranty, the operator must maintain the generator as

instructed in this manual.

Some adjustments will need to be made periodically to properly maintain your generator.

All service and adjustments should be made at least once each season. Follow the requirements

in the Maintenance Schedule chart above.

Notice Once a year you should clean or replace the spark plug and replace the air filter. New

spark plugs and clean air filter assure proper fuel-air mixture and help your engine run better

and last longer.

English Customer Service: 1-844-FIRMAN1

MAINTENANCE SCHEDULE

ITEM NOTES Daily(Before

operation)

Initial

25 hours

Every

50 hours

Every

100 hours

(or annual)

Fittings/

Fasteners

Spark Plug

Engine Oil

Air Filter

Fuel Line

Exhaust

System

Engine

Check condition. Adjust gap

and clean. Replace if necessary.

Check oil level.

Clean, replace if necessary.

Check for leakage. Retighten or

replace gasket if necessary.

Check adjust valve clearance.

Clean combustion chamber.

Check. Replace if necessary.

Check fuel hose for cracks or other

damage. Replace if necessary.

√

√

√

√

√

√

√

√

√

√

Replace.

Check spark arrester screen.

Clean/Replace if necessary.

√

Check for damage and leaks.

Replace if necessary.

LPG Regulator

/Hose Assy.

Every

250 hours

√

To be performed by knowledgable/experienced owner or by authorized service center.

*

*

*

Page 28

English Customer Service: 1-844-FIRMAN1

ENGINE MAINTENANCE

Air Filter Maintenance

Use fresh and high quality lubricating oil to the

specified quantity.

If contaminated or deteriorated oil is used or

the quantity of the engine oil is not sufficient,

the engine damage will result and its life will be

greatly shortened.

Change Engine Oil

To prevent accidental starting, remove and

ground spark plug wire before performing any

service.

If you are using your generator under extremely

dirty or dusty conditions, or in extremely hot

weather, change the oil more often.

Avoid prolonged or repeated skin contact with

used motor oil.

CAUTION

•

Change engine oil every 100 hours.

(for a new engine, change oil after 25 hours.)

Maintaining an air filter in proper condition is

very important. Dirt induced through improperly

installed, improperly serviced, or inadequate

elements damages and wears out engines.

Always keep the element clean.

(

(d) Put the element in the case and install it

securely.

(a) Remove the air cleaner cover and locate the

air filter plastic cover.

(e) Reattach the air filter cover.

(f) Reinstall the air cleaner cover and tighten the

cover screw securely.

c) After wetting the element by clean engine

oil squeeze it tight by hand.

(b) Remove the foam element.

Foam Element

Air Cleaner

Used motor oil has been shown to cause skin

cancer in certain laboratory animals.

Thoroughly wash exposed areas with soap

and water.

•

•

(a) Loosen the cover screws and remove the

maintenance cover.

(b) Pop up the rubber plug from below yellow

draining bolt.

(c) Remove yellow drain bolt.

(d) Tilt the generator on its side and allow the oil to

drain completely.

(e) Replace yellow drain bolt.

(f)

. DO NOT OVERFILL.

Fill the engine with oil until it reaches the HIGH

(H) level on the oil filler cap

Page 29

Inspect Muffler and Spark Arrester

Inspect the muffler for cracks, corrosion, or

other damage. Remove the spark arrester, if

equipped, and inspect for damage or carbon

blockage. If replacement parts are required,

make sure to use only original equipment

replacement parts.

Exhaust heat/gases could ignite combustibles,

structures or damage fuel tank causing a fire,

resulting in death or serious injury and/or

property. Contact with muffler area could cause

burns resulting in serious injury.

WARNING

English Customer Service: 1-844-FIRMAN1

DO NOT touch hot parts and AVOID hot exhaust

gases.

Allow equipment to cool before touching.

Keep at least 5 feet (1.5 m) of clearance on all

sides of generator including overhead.

Replacement parts must be the same and

installed in the same position as the original

parts.

•

•

•

•

Clean or replace spark arrester as follows:

Depending on the type fuel used ,the type and

amount of lubricant used, and/or your operating

conditions, the exhaust part and muffler may

become blocked with carbon deposits. If you

notice power loss, you may need to remove these

deposits to restore performance.

1. Allow the engine to cool completely before

servicing the spark arrester.

2. Loosen the spark arrester clamp, remove the

spark arrester cover, and with a thin blade

screwdriver remove the spark arrester.

Spark Plug Maintenance

Changing the spark plug will help your engine

to start easier and run better.

(e) Adjust the electrode gap to 0.7 to 0.8 mm

(0.028” to 0.031”).

(f) Seat spark plug in position and thread by

hand to prevent cross threading.

(g) Tighten plug with provided wrench and put

the cap back on spark plug.

SPARK PLUG: FIRMAN P/N 330723001

or CHAMPION N9YC .

(d) I

with a wire brush before reinstalling

nspect spark plug for damage and clean

(a) Remove the maintenance cover.

(b) Remove the spark plug cable from the spark

plug.

(c)Remove spark plug using provided wrench.

Page 30

GENERATOR MAINTENANCE

Make certain that the generator is kept clean

and stored properly. Only operate the unit on

a flat, level surface in a clean, dry operating

environment. DO NOT expose the unit to

extreme conditions, excessive dust, dirt,

moisture or corrosive vapours.

DO NOT use a garden hose to clean the generator.

Water can enter the generator through the cooling

slots and damage the generator windings.

Use a damp cloth to clean exterior surfaces of

the generator.

Use a soft bristle brush to remove dirt and oil.

Use an air compressor (25 PSI) to clear dirt and

debris from the generator.

Inspect all air vents and cooling slots to ensure

that they are clean and unobstructed.

CAUTION

English Customer Service: 1-844-FIRMAN1

Failure to clean the spark arrester will result in

degraded engine performance.

CAUTION

4. Replace the spark arrester if it is damaged.

5. Position the spark arrester in the muffler and

attach spark arrester cover with the screws.

3. Carefully remove the carbon deposits from the

spark arrester screen with a wire brush. Battery Replacement

1.Unscrew the air cleaner cover by provided

screwdriver.

2. Release the battery retaining rubber belt.

3. Remove the protective cover(rubber sheath)

from battery.

4. Disconnect the black(-) cable from black(-)

terminal on the battery.

Disconnect the red(+) cable from red(+) terminal

on the battery.

Rubber Sheath

Battery

Positive(+)

Terminal

Negative(-)

Terminal

5. Pull out the battery and replace with new battery:

12V sealed lead acid 5.5AH

LXWXH:90X70X100mm(3.54X2.76X3.84in)

6. Connect the red(+)battery cable to the positive

terminal of battery first and then connect the black(-)

battery cable to the negative terminal of battery.

7. Reattach the air cleaner cover.

WARNING

ALWAYS connect the positive (+) battery cable

(red boot) first when connecting battery cables.

To avoid electric shock:

Red Cable

Black Cable

- Intake: 0.06 0.12 mm (0.002 - 0.004 in.)

- Exhaust: 0.08 - 0.14 mm (0.003 - 0.005 in.)

-

Maintenance Valve Clearance

To be performed by knowledgable/experienced

owner or by authorized service center.

Page 31

English Customer Service: 1-844-FIRMAN1

To ensure the battery remains charged, the

supplied battery charger should be plugged

into the generator. Plug the cord from the

charger into the charging port on the generator

control panel. Plug the charger into a 120 volt

There is a light on the charger. This light will

remain red until the battery get charged and

then it will be changed to green. The charger

won't charge the battery or will stop charging

when the light is green to prevent any damage

to battery and generator.

Unplug battery charger from wall outlet and

generator control panel when generator is

going to be used.

AC wall outlet.

ALWAYS disconnect the negative (-) battery

cable (black boot) first when disconnecting

battery cables.

NEVER connect the negative (-) battery cable

(black boot) to the positive (+) post on the

battery.

NEVER connect the positive (+) battery cable

(red boot) to the negative (-) post on the battery.

NEVER touch both battery posts simultaneously.

NEVER place a metal tool across both battery

posts.

ALWAYS use insulated or nonconducting tools

when installing the battery.

Charging The Generator Battery

WARNING

WARNING

SERVICE AND STORAGE

Infrequent Service

If the unit is used infrequently, difficult starting

may result. To eliminate hard starting, follow

these instructions:

1. Run the generator at least 30 minutes every

month.

2. Run the generator, then close the fuel shut-off

valve and allow the unit to run until the engine

stops.

3. Move the engine switch to the "OFF" position.

Long Term Storage

It is important to prevent gum deposits from forming

in essential fuel system parts such as the carburetor,

fuel hoses or tank during storage. Also, experience

indicates that alcohol-blended fuels (called gasohol,

ethanol or methanol) can attract moisture, which leads

to separation and formation of acids during storage.

Acidic gas can damage the fuel system of an engine

while in storage.

When the generator set is not being operated, or

is being stored more than one month, follow these

instructions to avoid engine problems:

1-ADD a properly formulated commercially FUEL

STABILIZER to the tank if it is not already added.

2-Operate the engine for 5-10 minutes to circulate

treated fuel into fuel lines and carburetor before

shutdown.

3- After engine cools down, remove all gasoline

from the fuel tank. Use a commercially available,

non-conductive vacuum siphon.

Page 32

English Customer Service: 1-844-FIRMAN1

DANGER

Drain fuel into approved container outdoors,

away from open flame. Be sure engine is cool.

Do not smoke.

4-FUEL STARVATION: Turn fuel selector switch

to “GAS” position. Start and run the generator until it

stops from lack of gasoline. This will dry out all

remaining gasoline in tank, fuel lines and carburetor.

5-Turn fuel selector switch to “OFF” position.

Fully close the LPG cylinder knob if it is open and

disconnect LPG cylinder from the generator.

6-Allow the unit to cool entirely before cleaning

and storage.

7-Change oil with recommended grade oil.

8-Remove spark plug and pour about one teaspoon

of engine oil through the spark plug hole, then pull

the recoil starter several times to distribute the oil for

lubricating the cylinder. Reattach the spark plug.

Pull recoil slowly until resistance is felt. This will

close the valves so moisture cannot enter engine

9-Cover the unit and store in a clean, dry place

out of direct sunlight. NEVER USE WATER TO

CLEAN GENERATOR.

cylinder. Gently release recoil starter.

We recommend always using a fuel stabilizer.

A FUEL STABLIZER will minimize the formulation

of fuel gum deposits during storage, the fuel

stabilizer can be added to the gasoline in the

fuel tank, or into the gasoline in a storage

container.

Note:

•

If it is not practical to empty the fuel tank and

the unit is to be stored for some time, use a

commercially available FUEL STABILIZER added

to the gasoline to increase the life of the gasoline.

Run the unit for 5-10 minutes to circulate treated

gasoline into the fuel lines abs carburetor before

shutdown. DO NOT STORE GENERATOR WITHOUT

FUEL STABILIZER IN FUEL SYSTEM INCLUDING

TANK, FUEL LINES AND CARBURETOR.

•

Any damages or hazards caused by using

improper fuel, improperly stored fuel, and/

or improperly formulated stabilizers, are not

Do not store gasoline from one season to

another season.

•

covered by manufacturer's warranty.

•

WARNING

Generator exhaust contains odorless and

colorless carbon monoxide gas.

To avoid accidental or unintended ignition of

your generator during periods of storage, the

following precautions should be followed:

When storing the generator for short or extended

periods of time make sure that the fuel selector

switch is in the “OFF” position and the battery

leads have been disconnected from the battery.

The battery powers up the starter motor and the control

module in this generator. This product is equipped with

an automatic battery charging circuit. The battery will

receive charging voltage when the engine is running.

The battery will maintain a proper charge if the unit is

used on a regular basis (about once every two weeks).

If it is used less frequently, the battery should be connected

to a trickle charger (not included) or battery maintainer (not

included) to keep the battery properly charged. If the

battery is not able to start the engine, it can be started

manually only on “GAS” position by pulling the engine

recoil cord. If the battery voltage is extremely low, the

charging circuit may not be able to re-charge the battery.

In this case, the battery must be connected to a standard

automotive style battery charger for re-charging before

it can be used.

Battery Charging & Maintenance

Repairs/Service Parts

We recommend that you use a FIRMAN authorized

dealer for all maintenance, service, and replacement

parts for engine. To find a FIRMAN authorized dealer

visit www.firmanpowerequipment or call

1-844-347-6261.

TROUBLE SHOOTING

Page 33

English Customer Service: 1-844-FIRMAN1

Problem Cause Correction

Engine is running, but no

AC output is available.

1. Circuit breaker is open.

2. Overload light is on.

3. Poor connection or defective cord

set.

4. Connected device is bad.

1. Reset circuit breaker.

2. Review the load and restart the unit.

3. Check all connections and cord set.

4. Replace defective device.

Engine runs good at

no-load but “bogs down”

when loads are connected.

1. Clogged or dirty fuel filter.

2. Clogged fuel line(Gasoline or LPG).

3. Generator is overloaded.

4. Clogged spark arrester.

1. Clean or replace fuel filter.

2. Clean the fuel line.

3. Check the load and adjust.

4. Clean or replace spark arrester.

Engine will not start; starts

and runs rough or shuts

down when running.

Engine lacks power.

Engine“hunts”or falters.

1. Fill crankcase to proper level/

Place generator on level surface.

2. Fill fuel tank with gasoline or Fill

LPG tank with propane(LPG).

3.Replace spark plug.

4. Connect wire to spark plug.

5. Clean or replace the fuel filter.

6. Fully open LPG(propane) cylinder

know.

7. Start engine in "GAS" position,

Charge or replace battery.