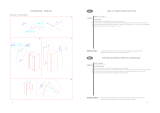

PRODUCT ATTRIBUTES

SCRATCHES

TEMPERATURE

STAINS

SUPERFICIAL

HUMIDITY

SPRAINS -

CRACKS

Distributed in North America by LIFT BRIDGE KITCHEN & BATH

(Strategic Retail )Solutions

(888) 930-8528

Distributed in other countries by FIRPLAK S.A

(+57 4) 444-1771

Manufactured and distributed by MILESTONE MUEBLES S.A.S

(+57 1) 796-5340

LIFT BRIDGE

KITCHEN & BATH

DRAWERS

Easy to assemble metal sided drawers.

Metal sided drawers can support a

maximum load of 55 lbs.

Up to 100,000 openings guaranteed by

Soft-closing mechanism allows drawers

HARDWARE

Up to 40,000 openings guaranteed by

each soft-closing hinge.

Steel hangers support a maximum load of

440 lbs. per cabinet.

WARNING

If you are concerned about the weight of the cabinet on the wall, we recommend using the

optional support legs (sold separately).

MATERIAL

Melamine material gives greater

resistance to:

Resistant to moisture and extreme temperatures.

Multiple melamine color options available.

Edge band on every exposed edge.

each drawer.

to always close soft and silent.

Double-wall mounting plate allows for easy

installation.

Benefits of particle board vs plywood.

Different finishes and textures.

Better finish quality.

The decorative paper does not take off.

If purchased in North America, please contact

the Lift Bridge Kitchen & Bath customer service

at (888) 930-8528 or

This furniture is manufactured with wood

from cultivated forests and is covered with:

Melamine material which gives

a greater resistance to:

M

E

L

A

M

I

N

A

C

A

D

E

x

c

l

u

s

i

v

M

O

D

U

A

R

T

®

SCRATCHES

STAINS

SUPERFICIAL

HUMIDITY

SPRAINS -

CRACKS

M

N

U

F

T

U

R

E

W

I

T

H

E

e

f

o

r

TEMPERATURE

Questions, problems, missing

parts?

If purchased in other countries,

please contact the Firplak S.A customer service

at (+57 4) 444-1771 or

servicioalcliente@firplak.com

Please read all instructions carefully.

Use a dry cloth to clean.

Fill the lower drawers first. Avoid opening

more than one drawer at a time.

Avoid getting the cabinet wet.

Do not allow children to climb on

the cabinet.

Do not paint the cabinet.

Do not drag the cabinet, empty the

cabinet and then lift and move.

READ BEFORE ASSEMBLY

RECOMMENDATIONS AND WARNINGS

Handle with care. Do not drop, handle

roughly, or overtighten screws as this will

cause damage to the wood.

We recommend using two people to assemble,

move or lift the cabinet.

Please contact the appropriate customer

service team if you have any questions.

The production lot number on the last page of

the installation manual will be needed

for warranty issues.

CERTIFICATE OF GUARANTEE

For us it is essential to work with high quality

materials and under certified processes

ISO 9001.

Our furniture has a 10-year Limited Warranty from

the date of purchase. It covers defects or parts

that prevent the correct assembly or usage.

This warranty includes the replacement of defective

parts and is valid as long as the assembly

instructions have been followed.

This warranty excludes damage caused by external

factors, deterioration due to being installed on

wet walls or damage from being exposed

directly to water.

Proof of purchase (original sales receipt) must be

made available for all warranty claims.

1010

This warranty excludes furniture that has been

assembled incorrectly and modified or repaired.

11

11

50201

X

E

X

13

12

13

12

50201 - 1 of 17

22

22

10

1

4

1

1

1

1

2

2

2

2

12

7

6

4

5

4

1

3

6

1

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

2

7

10

1

3

8

4

5

6

2

14

15

9

22

6

PLASTIC PLUG

SCREWS FOR HINGE AND

HINGE PLATES

16

16

ST

ANLEY

RUBBER HAMMER

QTY.

CONFIRMAT SCREW

QTY.

ALLLEN WRENCH

QUICK FIT CAM

QUICK FIT DOWEL

WOODEN PIN

PLASTIC CAM TAP

DOUBLE-WALL MOUNTING

PLATE

LEFT CABINET HANGER

RIGHT CABINET HANGER

EURO SCREWS

LARGE SELF DRILLING

SCREWS

ANCHOR

DRYWALL ANCHOR

PLASTIC PIN

SMALL SELF DRILLING

SCREWS

SINK

(NOT INSTALLED)

HAMMER

PLEASE READ THE INSTRUCTIONS

CAREFULLY BEFORE BEGINNING

THE ASSEMBLY

NOTE:

IT IS RECOMMENDED

TO ASSEMBLE THE

CABINET BETWEEN

TWO OR MORE PEOPLE.

DRILL

STUD FINDER

PENCIL

SILICONE

SCREWDRIVER

TAPE MEASURE

LEVEL

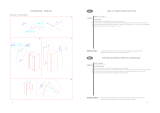

HOW TO ASSEMBLE YOUR HARDWARE

3. ASSEMBLY AND ADJUSTMENT OF THE CAM

Arrow pointing towards

the quick fit dowel

Turn (tighten) the cam

clockwise until it locks

in place.

Place the dowel

into the cam

4. ASSEMBLY OF THE PINS

place the wooden

pins into the

perforations

Use the hammer

gently to adjust

them

1. CAM

Place the quick fit cam

into the specific perforations

with the arrow pointing

towards the insertion

point.

Insertion

point

2. DOWEL

Place the quick fit

dowel into the specified

perforations

Screw the

dowel

clockwise

Until it

locks in

place

RIGHT CABINET HANGER

COVER

LEFT CABINET HANGER

COVER

CABINET PROFILES AND METALLIC

SIDE DRAWERS LEFT/RIGHT 13 3/4"

SOFT-CLOSING HALF OVERLAY

HINGE AND HINGE PLATE

37" VITELI VANITY CABINET

HARDWARE INCLUDED

CAUTION:

ASSEMBLE THE UNIT IN A FLAT AREA.

TOOLS INCLUDED

SOFT-CLOSING

MECHANISM

RIGHT CLIP FRONT FIXING

BRACKET

LEFT CLIP FRONT FIXING

BRACKET

SCREWS FOR SOFT-CLOSING

MECHANISM AND METAL SIDE

DRAWERS

TOOLS REQUIRED

SCREWS FOR ANCHOR

1

2

SURF

A

CE

SURF

A

CE

SURFA

CE

8

4

10

SURF

ACE

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

SURFA

CE

3

INSTALL PLASTIC PLUGS

SURF

A

CE

1

USING THE RUBBER

HAMMER INSTALL THE

PLASTIC PLUGS.

SURFA

CE

9

14

SURF

ACE

15

SURF

ACE

50201 - 2 of 17

INSTALL PINS

PLASTIC

PIN

PLASTIC

PIN

ASSEMBLY INSTRUCTIONS

USING THE RUBBER

HAMMER INSTALL THE

PLASTIC PLUGS.

7

4

FRONT

FRONT

SURFACE

5

50201 - 3 of 17

FRONT

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

SURFACE

1

5

SURF

ACE

SURFACE

9

3

ASSEMBLY INSTRUCTIONS

INSTALL CABINET PROFILES AND HANGERS

THE WHEEL SHOULD FACE

THE FRONT OF THE CABINET

AND DOWN.

THE WHEEL SHOULD FACE

THE FRONT OF THE CABINET

AND DOWN.

USE SCREWS FOR

SIDE DRAWERS

LEFT CABINET

HANGER

RIGHT CABINET

HANGER

APPLY PRESSURE TO

THE HANGERS TO FIT

SECOND AND EIGHTH HOLE

SECOND AND EIGHTH HOLE

SECOND AND EIGHTH HOLE

SECOND AND EIGHTH HOLE

NOTE:

THE SOFT-CLOSING MECHANISMS

ARE INSTALLED IN CABINET PIECE #5.

USE SCREWS FOR SOFT-

CLOSING MECHANISM

INSTALL SOFT-CLOSING MECHANISM

5

6

50201 - 4 of 17

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

4

1

SURF

ACE

Titus

SURFA

CE

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

1

Titus

3

2

2

ASSEMBLY INSTRUCTIONS

Cam adjustment

INSTALL PIECE 1-2-3

NOTE:

REMEMBER TO ASSEMBLE THE CABINET

BETWEEN TWO OR MORE PEOPLE.

INSTALL PIECE 4

NOTE:

REMEMBER TO ASSEMBLE THE CABINET

BETWEEN TWO OR MORE PEOPLE.

Cam adjustment

7

8

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

6

SURFACE

1

50201 - 5 of 17

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

SURF

ACE

4

5

ASSEMBLY INSTRUCTIONS

INSTALL PIECE 5

USE CONFIRMAT

SCREWS

NOTE:

REMEMBER TO ASSEMBLE THE CABINET

BETWEEN TWO OR MORE PEOPLE.

Cam adjustment

INSTALL PIECE 6

NOTE:

REMEMBER TO ASSEMBLE THE CABINET BETWEEN TWO OR MORE PEOPLE.

HOLD PIECE 6 UNTIL

PIECE 9 IS ASSEMBLED

9

10

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

5

8

SURF

A

CE

50201 - 6 of 17

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

1

SURF

A

CE

ASSEMBLY INSTRUCTIONS

Cam adjustment

INSTALL PIECE 7

NOTE:

REMEMBER TO ASSEMBLE THE CABINET BETWEEN TWO OR MORE PEOPLE.

HOLD PIECES 6-7 UNTIL

PIECE 9 IS ASSEMBLED

Cam adjustment

INSTALL PIECE 8

HOLD PIECES 6-7-8 UNTIL

PIECE 9 IS ASSEMBLED

7

11

12

50201 - 7 of 17

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

SURFA

CE

4

2

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

SURFACE

4

6

2

3

2

9

8

4

9

3

2

8

6

7

2

ASSEMBLY INSTRUCTIONS

Cam adjustment

INSTALL PIECE 9 WITH PIECES 2-3-4-6-7 AND 8

INSTALL SCREWS TO PIECE 2 BELOW PIECE 4

USE LARGE SELF

DRILLING SCREWS

7

13

14

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

50201 - 8 of 17

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

SURFA

CE

SURFACE

ASSEMBLY INSTRUCTIONS

LIFT THE CABINET

LIFT THE

CABINET

CAUTION:

TWO PEOPLE ARE NEEDED TO SAFELY LIFT THE CABINET.

INSTALL PIECE 10 AND AJUST PIECE 2

REAR VIEW

USE SMALL SELF

DRILLING SCREWS

USE CONFIRMAT

SCREW

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

10

7

2

2

5

SURF

ACE

15

16

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

2

SURFA

CE

11

12

12

11

SURFACE

11

1

11

50201 - 9 of 17

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

11

12

SURFACE

ASSEMBLY INSTRUCTIONS

ASSEMBLE PIECES 11-12

USE LARGE SELF

DRILLING SCREWS

NOTE:

REMEMBER TO ASSEMBLE THE CABINET

BETWEEN TWO OR MORE PEOPLE.

INSTALL METAL SIDE DRAWERS

USE SCREWS FOR

METAL SIDE

DRAWERS

FIT THE METAL SIDE

DRAWERS AND SCREW

18

17

SURF

ACE

13

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

50201 - 10 of 17

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

SURFACE

11

11

ASSEMBLY INSTRUCTIONS

INSTALL SOFT-CLOSING MECHANISM

USE SCREWS FOR

SOFT-CLOSING MECHANISM

INSTALL CLIP FRONT FIXING BRACKET LEFT/RIGHT

NOTE:

DO NOT TIGHTEN THE

SCREWS COMPLETELY

19

20

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

W

ALL

1

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

W

ALL

2

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

13

13

9

50201 - 11 of 17

9

1

3

SURF

A

CE

11

13

1

11

13

2

11

13

3

4

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

SURF

ACE

SURFACE

ASSEMBLY INSTRUCTIONS

ASSEMBLE UPPER AND LOWER DRAWERS

NOTE:

TIGHTEN THE SCREWS

COMPLETELY

NOTE:

MAKE SURE THAT THERE IS NO

SPACE BETWEEN PIECE 11-13.

INSTALL SINK, CABINET HANGER COVERS AND DRAWERS

HEIGHT ADJUSTMENT

DRAWER

HITCH

DISENGAGEMENT

OF THE DRAWERS

NOTE:

IF YOU BOUGHT THE OPTIONAL LEGS FOR YOUR

CABINET THEN PLEASE FOLLOW THE INSTALLATION

GUIDE ON PAGE 14 BEFORE YOU MOUNT THE

CABINET ON THE WALL.

NOTE:

WHEN MOUNTING THE CABINET ON THE WALL

USE THE INSTALLATION GUIDE ON PAGE 15.

NOTE:

ONCE THE CABINET IS MOUNTED ON THE WALL,

FOLLOW VANITY TOP INSTALLATION.

INSTRUCTIONS (INCLUD WITH THE VANITY TOP)

NOTE:

INSTALL THE DRAWERS AND PLACE THE HANGER

COVERS ON THE HANGERS AFTER THE CABINET

HAS BEEN MOUNTED ON THE WALL.

22

21

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

50201 - 12 of 17

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

14

SURF

A

CE

WALL

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

1

15

SURFA

CE

USE SCREWS FOR

HINGES PLATES

USE SCREWS

FOR HINGES

ASSEMBLY INSTRUCTIONS

INSTALL HINGES AND HINGE PLATES

SEE STEP 22

SEE STEP 22

HINGE ASSEMBLY AND DOOR ADJUSTMENT

3

DOOR

CLICK

2

DOOR

DOOR

SIDE

INSERT THE HINGE IN

THE BASE

SLIDE HINGE

VERTICAL AJUSTMENT

To move the door

up and down.

HORIZONTAL ADJUSTMENT

To move the door left or right.

“CLICK”

BASE

BISAGRA

“Hinge plate”

“Hinge”

P

ANELS

SIDE

PANELS

SIDE

PANELS

1

PRESS UNTIL IT CLICKS

DEPTH ADJUSTMENT

To move the door

forwards and backwards.

TO REMOVE THE DOOR USE

THE FOLLOWING ACTION:

W

ALL

IMAGEN FINAL DEL MUEBLE

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

19

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

50201 - 13 of 17

ASSEMBLY INSTRUCTIONS

FINAL IMAGE OF THE CABINET

SURFA

CE

9

1

W

ALL

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

4

50201 - 14 of 17

SURF

A

CE

USE SCREWS

FOR LEGS

NOTE:

USE THE LEG LEVELER TO

ADJUST THE HEIGHT.

FOLLOW THESE STEPS IF YOU

PURCHASED LEGS FOR YOUR VANITY

GUIDE TO INSTALL THE OPTIONAL VANITY LEGS

INSTALLATION OF THE LEGS MUST

BE DONE AFTER THE CABINET IS

ASSEMBLED BUT BEFORE IT IS

MOUNTED TO THE WALL.

INSTALL LEGS IN PIECE 4.

NOTE:

TWO PEOPLE ARE REQUIRED TO SAFELY LIFT THE CABINET

ST

ANLEY

STANLEY

A B C

D E F

G

50201 - 15 of 17

H

WALL

1

ST

ANLEY

DRILL

STUD FINDER

TAPE MEASURE

ATTACHING THE MOUNTING PLATE

LEVEL

SCREWDRIVER

SILICONEPENCIL

28"

-

28"

11/32

27/64

TOOLS REQUIRED (NOT INCLUDED)

GUIDE TO MOUNTING THE CABINET ON THE WALL

MEASURE FROM THE EDGE

OF THE FLOOR UP.

MARK A HORIZONTAL LINE

WITH THE LEVEL AS A GUIDE TO

INSTALL THE MOUNTING PLATE.

WITH THE STUD FINDER LOCATE THE

STUDS AND MARK THEM WITH AN X,

THEN MARK A LINE IN THE CENTER

OF THE DRAINAGE.

DRILL A MOUNTING HOLE IN THE

INTERSECTION OF THE TWO LINES.

INSERT THE DRYWALL ANCHOR USING

THE SCREWDRIVER.

INSERT THE SCREW INTO THE

DRYWALL ANCHOR.

WITH THE LEVEL OVER THE MOUNTING

PLATE MAKE SURE THAT THE PLATE IS

LEVEL ON BOTH SIDES.

INSERT THE OTHER ANCHORS DIRECTLY

INTO THE STUDS USING A DRILL WITH A

HEXAGONAL BIT.

(Follow this guide if you are using the optional legs. Otherwise, install the mounting plate at your desired height)

2

2

50201 - 16 of 17

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

ST

ANLEY

C

F

I

J

G

D

A

B

H

E

GUIDE TO MOUNTING THE CABINET ON THE WALL

HANG THE CABINET ON THE WALL

WITH TWO OR MORE PEOPLE LIFT THE

CABINET UP ONTO THE MOUNTING PLATE.

MAKE SURE THAT THE HANGER IS

ATTACHED TO THE PLATE.

MARK THE DRILL GUIDES ON PIECE 2, NOTE THAT

THEY MUST BE ALIGNED WITH THE SCREWS AT THE END OF

THE PLATE, AND THEN REMOVE THE CABINET FROM THE WALL.

DRILL ON THE MARKS

PREVIOUSLY MADE.

INSERT THE ANCHORS THROUGH

PIECE 2.

ONCE AGAIN LIFT THE CABINET AND

ATTACH IT TO THE MOUNTING PLATE.

MAKE SURE THAT THE HANGERS ARE

COMPLETELY ATTACHED TO THE PLATE

AND THEN TIGHTEN THE ANCHORS.

INSTALL THE DRAWERS AND PLACE

THE HANGER COVERS OVER THE HANGERS.

LEVEL THE CABINET.

IF THE CONNECTIONS ARE NOT

WITHIN THIS RANGE IT IS NECESSARY

TO DO PLUMBING WORK FIRST.

21"

17/64

22"

53/64

7/16"

3/4"

3 Regulations

Height 7/16"

Front 3/4"

Side 5/16"

9

1

9

1

9

1

2

2

2

2

9

13

13

50201 - 17 of 17

BLUMOTION

L

FRONT

BLUMOTION

L

FRONT

Enjoy your unit!!

OP No:

Installation instructions / Instrucciones de instalación

Important / Importante

Assemble the faucet and

drain on the sink before you

install it on the vanity.

Instale la grifería y el desagüe

en el lavamanos antes de fijar

el lavamanos en el mueble.

Identify what type of faucet to install,

Faucet 0 " (already pre-drilled), Faucet 4"

or Faucet 8 "

Identifique que tipo de grifería va instalar

Grifería 0” (ya están previamente perfora-

dos), Grifería 4” o Grifería 8”

See drilling instructions if required. Page.3

Ver instrucciones de perforación si lo requiere. Pag.3

Flexible P trap /

Desagüe flexible

Install supply connections if

you do not have them.

Instale las llaves de abasto si

no las tiene.

Install the drain.

Instale el desagüe.

Install the P trap or flexible P trap to the wall

Instale el sifón o sifón flexible en la pared.

1

Vanity Top Installation

Instructions

Instrucciones de instalación

Para lavamanos vanity

Water supply

connections /

Conexiones de agua

Illustrative image / Imagen ilustrativa

bottom view / Vista inferior

A

B C

Drill-out guides located on the underside of the sink

Guías de pre-ponchado bajo la superficie del lavamanos

0”

4”

8”

Distributed by:

Liftbridge Kitchen & Bath.

For customer support please email : support@strategicretail-

solutions.com, or call (888)930-8528.

Manufactured by FIRPLAK S.A

(574) 444 1771

servicioalcliente@firplak.com

This vanity top uses a

drain without an

overflow.

Este lavamanos debe instalarse

con un desagüe sin rebose.

ATTENTION

ATENCIÓN

Once the adhesive has cured, connect

the drain and water supply lines.

Strengthen connections with Teflon

tape to prevent leakage.

Una vez que el adhesivo haya secado,

conecte las conexiones de desagüe y

suministro de agua. Refuerce las

conexiones con cinta de teflón, para

evitar fugas.

Remove the sink and add a thin bead

of silicone adhesive around the edge

of the cabinet and carefully set the

sink top on the vanity.

Levante el lavamanos y agregue un

cordón fino de adhesivo de silicona

alrededor del borde del mueble, luego

ubique cuidadosamente el lavamanos

sobre el mueble.

2

3

Turn the water on to test for leaks

and make any necessary

adjustments.

Deje correr el agua y verifique que no

haya fugas, ajuste conecciones si es

necesario.

4

5

6

bottom view / Vista inferior

If you want to seal between the wall and sink,

apply antifungal silicone between sink, the cabinet

and the wall, use masking tape for a clean

application.

Si desea tener un sellamiento entre la pared y el

lavamanos, aplique silicona antihongos entre el

lavamanos, el mueble y la pared, use cinta de

enmascarar para lograr una aplicación limpia.

• Lavamanos

• Silicona antihongos

• Cinta teflón

• Mueble

• Grifería y desagüe

• Sifón flexible*

• Sifón

• Tornillos y chazos

• Sink

• Antifungal Silicon

• Teflon tape

• Cabinet

• Faucet and drain

• Flexible P trap*

• P trap

• Screws and drywall anchor

Tools and parts

Herramientas y partes

Let it dry for

24 hours

Dejar secar

24 horas

Tape / Cinta

Silicone / Silicona

With the faucet installed and the help

of another person, place the sink on

the cabinet making sure the drain and

lines fit correctly.

Con la ayuda de otra persona, ubique el

lavamanos en el mueble y asegurese

que el desagüe y el sifón estén

alineados.

Teflon tape /

Cinta de teflón

Drilling Instructions for

Faucet Installation

Instrucciones de perforación

para la instalación de grifería

2

From the underside of the sink make a small hole using the

guide drill bit, aiming for the center of the hole where you want

to install the faucet.

Haga una pequeña perforación solo con la broca guía, buscando el

punto céntrico del orificio en el que desee instalar la grifería.

3

From the topside drill the holes guided by the marks made by

the drill bit, using the 1-¼” hole saw.

Perfore los orificios insinuados para instalar la grifería usando la

copa sierra de 1-¼”. Esto se debe hacer con el lavamanos hacia

arriba. Este proceso se repite para las perforaciones que la

grifería requiera.

4

After drilling the hole, polish any scuffs with 60 grit sandpaper,

proceed to install the faucet, according to the faucet's manual.

Después de perforar el orificio, pula con lija 60 y proceda a

instalar la grifería de acuerdo al manual de la griferia.

Taladro broca (guía) 1/8”

1/8 " Drill bit (guide)

Broca cierra de 1 ¼”

1-¼” hole saw

Lija grano 60

60 grit sandpaper

1

Identifique el tipo de grifería que se va a instalar 0”, 4” o 8”, para

perforar los orificios correctos.

Identify the type of faucet for your sink 0”, 4” and 8”, in order to

drill the right holes.

0”

4”

8”

Distributed by:

Liftbridge Kitchen & Bath.

For customer support please email : support@strategicretail-

solutions.com, or call (888)930-8528.

Manufactured by FIRPLAK S.A

(574) 444 1771

servicioalcliente@firplak.com

Cleaning High Gloss Finishes / Limpieza para acabado brillante

This material is manufactured with a high-gloss coating called a gel-coat which becomes an integral part of the product.

The gel coat layer is resistant to most staining agents. However, products containing harsh chemicals or acids (hair color,

acetone nail polish remover, etc.) can damage the finish if allowed to remain on gel coat surface for an extended period.

Any cleaning should be handled the same as the automotive finish on your car. Use a mild non-abrasive cleanser, liquid

dish soap, baking soda and water, or vinegar and water with a soft cloth or sponge. (Do not use scotch-brite pads, scour-

ing pads, steel wool, scrapers, or sandpaper) DO NOT USE ABRASIVE CLEANERS.

Before using any cleaner, be sure to read the label for recommended usage and warnings. To remove hard water stains

or mineral deposits, use a vinegar soaked soft cloth to soak area for an extended period and then wipe clean. Protect the

surface with regular applications of automotive wax.

Este material se fabrica con un recubrimiento de alto brillo denominado gel coat que se convierte en una parte integral del

producto. La capa de revestimiento de gel es resistente a la mayoría de las manchas. Sin embargo, los productos que

contienen químicos fuertes o ácidos (colorante para el cabello, removedor de esmalte de uñas de acetona, etc.) pueden dañar

el acabado si se deja permanecer en la superficie del gel coat durante un período prolongado.

Cualquier limpieza se debe manejar igual que el acabado automotriz en su coche. Use un limpiador no abrasivo, suave, jabón

líquido para platos, bicarbonato de sodio y agua, vinagre y agua con un paño suave o una esponja. (No utilice esponjas

scotch-brite, almohadillas de fregar metálicas, raspadores o papel de lija) NO UTILICE LIMPIADORES ABRASIVOS.

Antes de usar cualquier limpiador, asegúrese de leer la etiqueta para el uso recomendado y las advertencias. Para eliminar

manchas de agua dura o depósitos de minerales, use un paño suave empapado de vinagre para remojar el área por un perío-

do prolongado y luego limpie. Proteja la superficie con aplicaciones regulares de cera automotriz.

Cultured Marble / Mármol cultivado

Maintenance Guide

Sinks, laundry sinks and kitchen

sinks

Guía de mantenimiento / Lavamanos,

lavarropas y lavaplatos.

Cultured Marble is a man-made, chemically bonded, mineral-filled, polymeric material, which is molded and hardened in

a variety of shapes.

El mármol cultivado es un material polimérico de origen mineral, químicamente fusionado, fabricado artificialmente que se

moldea y endurece en una variedad de formas.

Distributed by:

Liftbridge Kitchen & Bath.

For customer support please email : support@strategicretail-

solutions.com, or call (888)930-8528.

Manufactured by FIRPLAK S.A

(574) 444 1771

servicioalcliente@firplak.com

To remove fine scratches, scuffmarks or light stains from your high gloss product use an automotive buffing compound

or baking soda and a hand-held polisher.

Deeper scratches may require wet sanding with appropriate sandpaper (600, 800, 1000). To bring the shine back, buff

with an automotive buffer and polishing compound.

Do not use rubbing compound, as this is too coarse. A professional should handle deep scratches. You MUST be careful

NOT to buff or sand through the gel coat surface. Once this is done, the piece is no longer protected in that spot. Protect

the surface with regular applications of automotive wax.

Para quitar rayones superficiales o las manchas ligeras de su producto con apariencia brillante utilice cera para automóviles

o un bicarbonato de sodio y un pulidor manual.

Las rayas más profundas pueden requerir lijado en húmedo con papel de lija apropiado (600, 800, 1000). Para traer el brillo

de nuevo, puede utilizar cera para automóviles.

No utilice rubbing compound (pasta pulidora) ya que es demasiado abrasiva. Un profesional debe manejar rayas profundas.

Debe tener cuidado de no pulir con polvo o arena sobre la superficie del producto. Una vez hecho esto, la pieza ya no estará

protegida en ese lugar. Proteja la superficie con aplicaciones regulares de cera para automóviles.

Removing scratches – High Gloss Finishes / Para eliminar rayones en acabado brillante

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

Lift Bridge Kitchen & Bath 37VSIEWAL Guía de instalación

- Tipo

- Guía de instalación

en otros idiomas

Artículos relacionados

Otros documentos

-

Frost King UDS36 Instrucciones de operación

Frost King UDS36 Instrucciones de operación

-

DANCO 88735 Manual de usuario

-

Blum BP38N35508180S Instrucciones de operación

-

LaToscana OAC024DR Guía de instalación

LaToscana OAC024DR Guía de instalación

-

allen+roth allen roth 1483VA-48-201 48-In Vanity Manual de usuario

-

GE GXWH37F Manual de usuario

-

Decor Living EV326W Guía de instalación

-

Sheffield Home EV333 Guía de instalación

Sheffield Home EV333 Guía de instalación

-

RCI KVSB36-SSW Guía de instalación

-

Sheffield Home EV24E3 Instrucciones de operación

Sheffield Home EV24E3 Instrucciones de operación